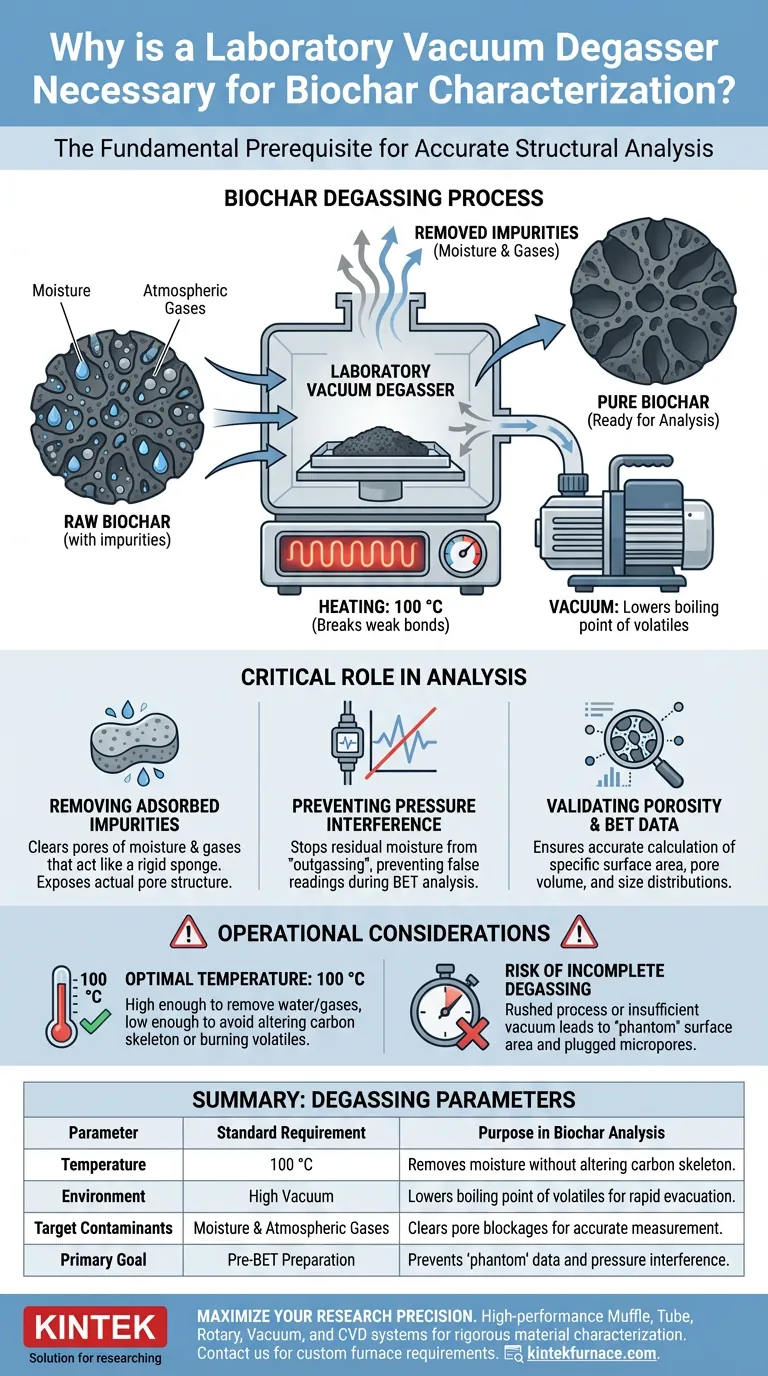

A laboratory vacuum degasser is a fundamental prerequisite for the accurate structural characterization of biochar. Before analysis can begin, this device prepares the sample by subjecting it to vacuum conditions at elevated temperatures—specifically 100 °C—to strip away adsorbed impurities. This process clears the pores of moisture and environmental gases, ensuring that subsequent measurements reflect the true nature of the biochar rather than contaminants.

The purity of the sample dictates the quality of the data. By removing residual moisture and gases that naturally cling to biochar, a vacuum degasser prevents these impurities from skewing sensitive pressure measurements, ensuring reliable surface area and porosity calculations.

The Critical Role of Degassing in Biochar Analysis

To understand biochar structure, you must first eliminate external variables. The vacuum degasser acts as the "reset" button for the material's internal environment.

Removing Adsorbed Impurities

Biochar is highly porous, acting essentially like a rigid sponge. In its natural state, these pores are filled with atmospheric moisture and gases.

If these impurities are left in place, they occupy the very space you are trying to measure. The degasser physically evacuates these substances to expose the actual pore structure.

The Function of Heat and Vacuum

The process relies on a specific combination of thermal energy and negative pressure.

According to standard protocols, the biochar is heated to 100 °C under vacuum. The heat provides enough energy to break the weak bonds holding moisture to the biochar surface, while the vacuum lowers the boiling point of volatiles, facilitating their rapid removal.

Ensuring Accuracy in BET Analysis

The primary reason for degassing is to prepare the sample for Brunauer-Emmett-Teller (BET) analysis, the gold standard for measuring specific surface area.

Preventing Pressure Interference

BET analysis works by measuring how gas interacts with the solid surface at specific pressures.

If the sample contains residual moisture, it will "outgas" during the analysis. This releases extra gas molecules into the system, interfering with the sensitive pressure sensors and creating false readings.

Validating Porosity Parameters

The presence of contaminants does not just affect surface area; it distorts porosity data as well.

Blocked pores cannot be measured. By using a degasser to clear these pathways, you ensure that the calculated pore volume and size distributions are accurate representations of the biochar's physical architecture.

Operational Considerations

While necessary, the degassing process requires careful control to balance cleaning efficiency with sample integrity.

Temperature Constraints

The target temperature of 100 °C is deliberate. It is high enough to drive off water and atmospheric gases but generally low enough to avoid structurally altering the carbon skeleton of the biochar.

Exceeding this temperature significantly could inadvertently activate the biochar further or burn off volatile organic compounds that are part of the sample's actual composition.

The Cost of Incomplete Degassing

Attempting to shorten this step is a common source of analytical error.

If the degassing phase is rushed or the vacuum is insufficient, "phantom" surface area results may occur. The data may show lower porosity than exists in reality because the smaller micropores remain plugged with water molecules.

Ensuring Reliable Characterization Results

To derive meaningful insights from your biochar research, apply the following principles during sample preparation:

- If your primary focus is Data Accuracy: Ensure the degassing protocol strictly maintains 100 °C under vacuum to fully evacuate pores without damaging the sample structure.

- If your primary focus is Process Troubleshooting: Look at the degassing stage first if your BET surface area results appear inexplicably low or inconsistent.

Proper degassing is the invisible foundation upon which all valid structural biochar data is built.

Summary Table:

| Parameter | Standard Requirement | Purpose in Biochar Analysis |

|---|---|---|

| Temperature | 100 °C | Removes moisture without altering the carbon skeleton |

| Environment | High Vacuum | Lowers boiling point of volatiles for rapid evacuation |

| Target Contaminants | Moisture & Atmospheric Gases | Clears pore blockages for accurate measurement |

| Primary Goal | Pre-BET Preparation | Prevents 'phantom' data and pressure interference |

Maximize Your Research Precision with KINTEK

Don't let sample impurities compromise your data integrity. KINTEK provides high-performance laboratory solutions specifically designed for rigorous material characterization. Backed by expert R&D and manufacturing, we offer high-temperature Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the specific degassing and thermal processing needs of your biochar research.

Ready to achieve superior accuracy in your lab? Contact us today to discuss your custom furnace requirements with our technical specialists.

Visual Guide

References

- Fairuz Gianirfan Nugroho, Abu Talha Aqueel Ahmed. Utilizing Indonesian Empty Palm Fruit Bunches: Biochar Synthesis via Temperatures Dependent Pyrolysis. DOI: 10.3390/nano15010050

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What functions do high-purity sulfur powder and ceramic boats serve in TB-MoS2 prep? Precision in 2D Material Synthesis

- How does a high-performance temperature controller contribute to repeatability? Precision for FTO Thin Film Annealing

- How does a laboratory drying oven function in catalyst synthesis? Secure Precision Metal Precursor Stabilization

- How does a lab vacuum pump work? Understanding the Liquid Piston Mechanism

- What role do high-purity graphite molds and punches play during the sintering of silicon carbide ceramics in SPS?

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- Why use high-purity quartz glass tubes for copper sulfide synthesis? Ensure Thermal Stability & Purity

- What is the purpose of utilizing a glassy carbon crucible and HCl gas treatment? Ensure Pure Molten Salt Systems