Repeat sintering processes and specialized molds solve the geometric limitations of standard manufacturing by allowing large flywheel components to be built in segments and fused into a single unit. When a rotor exceeds the size of a standard isostatic pressing chamber, engineers join multiple pre-sintered parts using precision machining and a second high-temperature treatment to create a seamless bond.

The core challenge of manufacturing oversized rotors is not just size, but maintaining structural unity. By leveraging the diffusion bonding mechanism of liquid phase sintering, this method allows for the creation of massive, complex structures that retain the material integrity of a single-piece component.

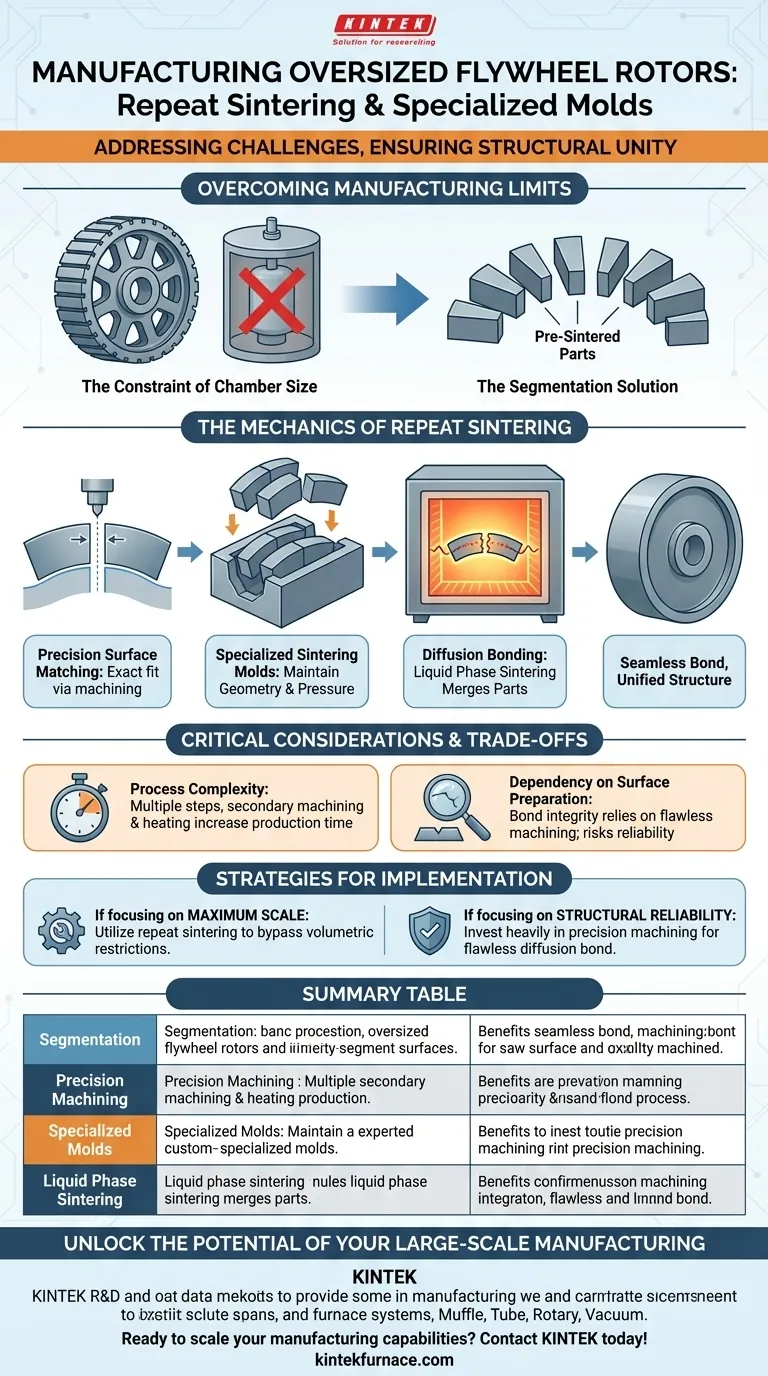

Overcoming Manufacturing Limits

The Constraint of Chamber Size

Standard manufacturing equipment has hard physical limits. specifically, isostatic pressing chambers cannot accommodate oversized flywheel rotor components in a single run.

The Segmentation Solution

To bypass this limitation, manufacturers produce the component in smaller, manageable segments. These parts are pre-sintered individually before being assembled for the final joining process.

The Mechanics of Repeat Sintering

Precision Surface Matching

For the segments to fuse correctly, the fit must be exact. The contact surfaces of each pre-sintered part undergo precision machining to ensure perfect alignment.

The Role of Specialized Molds

Once machined, the parts are assembled and placed into specialized sintering molds. These molds are critical for maintaining the correct geometry and pressure during the secondary heating phase.

Diffusion Bonding

During the second high-temperature treatment, the process triggers liquid phase sintering. This creates a diffusion bonding mechanism, effectively merging the separate parts into a reliable, unified structure.

Critical Considerations and Trade-offs

Process Complexity

While this method solves size constraints, it introduces multiple processing steps. The requirement for secondary machining and a second heating cycle increases production time compared to single-piece manufacturing.

Dependency on Surface Preparation

The integrity of the final bond is entirely dependent on the quality of the contact surfaces. If the precision machining is flawed, the diffusion bond may be compromised, risking the reliability of the component.

Strategies for Implementation

To ensure success when manufacturing oversized flywheel components, consider the following strategic priorities:

- If your primary focus is Maximum Scale: Utilize repeat sintering to bypass the volumetric restrictions of your available isostatic pressing equipment.

- If your primary focus is Structural Reliability: Invest heavily in the precision machining of contact surfaces to ensure the liquid phase sintering results in a flawless diffusion bond.

Mastering this multi-stage process transforms the limitations of your machinery into new possibilities for scale and complexity.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Segmentation | Component built in smaller, manageable parts | Overcomes isostatic pressing chamber limits |

| Precision Machining | Exact surface matching of pre-sintered parts | Ensures flawless alignment for bonding |

| Specialized Molds | Custom fixtures for secondary heating | Maintains geometry and pressure during fusion |

| Liquid Phase Sintering | High-temp diffusion bonding mechanism | Creates a seamless, unified structural bond |

Unlock the Potential of Your Large-Scale Manufacturing

At KINTEK, we understand that specialized projects require specialized solutions. Backed by expert R&D and world-class manufacturing, we provide the precision Muffle, Tube, Rotary, and Vacuum furnace systems necessary to master complex processes like repeat sintering and diffusion bonding. Whether you need a standard setup or a fully customizable high-temperature furnace for unique flywheel rotor production, our team is ready to deliver the reliability and performance your lab demands.

Ready to scale your manufacturing capabilities? Contact us today to discuss your unique needs!

Visual Guide

References

- Adéla Macháčková, Silvie Brožová. Applications of Tungsten Pseudo-Alloys in the Energy Sector. DOI: 10.3390/app14020647

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why use high-precision gas flow control for argon in oil migration simulations? Achieve Re=215 Accuracy

- What is the specific function of the water circulation cooler in zirconium sponge processing? Key for Purity & Safety

- How does surface finish impact the performance of alumina ceramic furnace tubes? Boost Purity and Efficiency

- What are the functions of BN crucibles and embedding powders in Si3N4 sintering? Expert Guide to Material Stability

- How do cooling modules in high-temperature laboratory furnaces manage thermal energy? Protect Your System Components

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- Why is an air-cooled stainless steel sampling probe utilized? Ensure Accurate High-Temp Combustion Analysis

- What is the role of quartz capillaries in the vacuum sealing process of sulfur? Enhance Purity and In-Situ Analysis