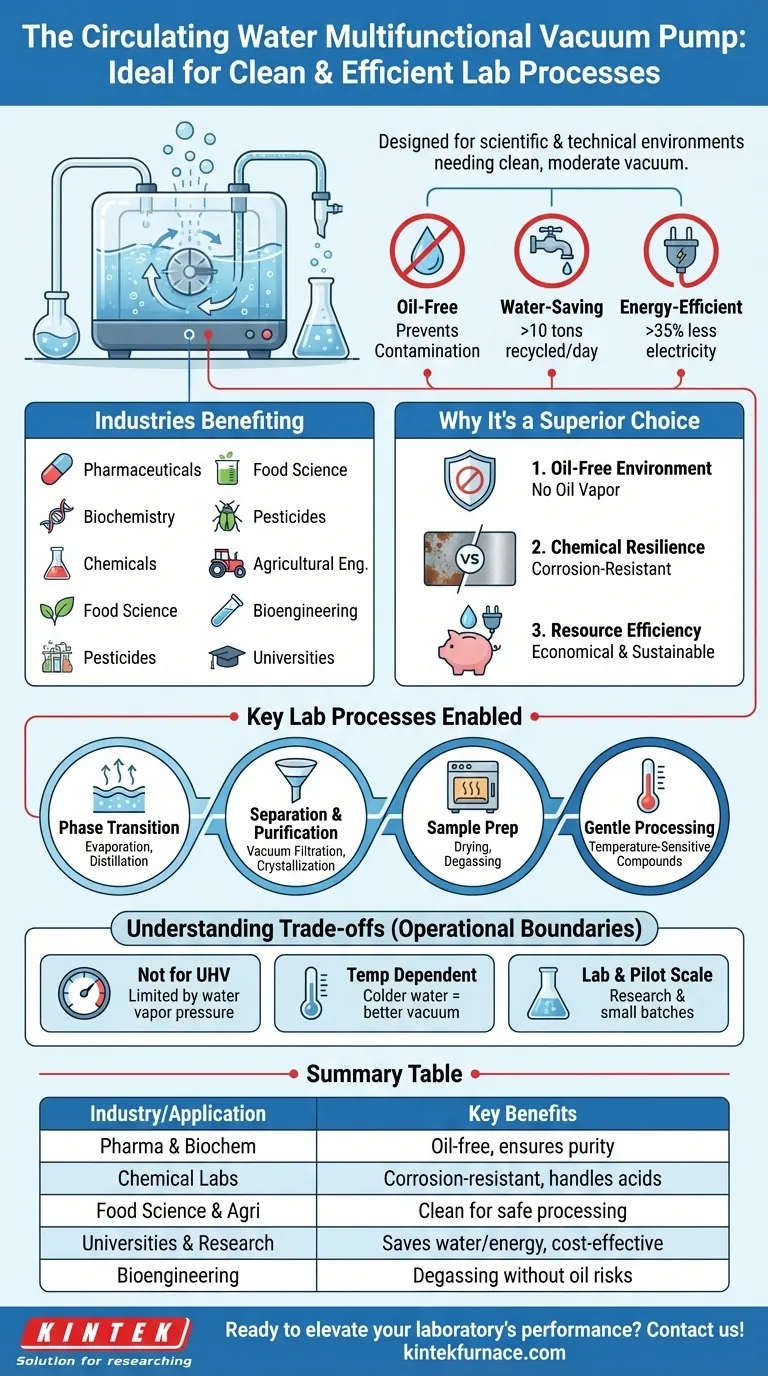

At its core, the circulating water multifunctional vacuum pump is designed for scientific and technical environments where a clean, moderate vacuum is essential. It is particularly beneficial for laboratories in universities and for industries such as pharmaceuticals, biochemistry, chemicals, food science, pesticides, agricultural engineering, and bioengineering.

This pump's primary value is not just in creating a vacuum, but in doing so without oil contamination while conserving significant amounts of water and energy. This unique combination makes it indispensable for laboratory and small-scale production processes where purity and operational efficiency are paramount.

Why These Industries Rely on Water-Based Vacuum

The suitability of this pump extends beyond a simple list of industries. It is the underlying principles of its operation that make it a superior choice for specific scientific and research contexts.

The Critical Need for an Oil-Free Environment

Many applications, especially in biology and pharmaceuticals, cannot tolerate even trace amounts of oil contamination.

An oil-based vacuum pump risks introducing oil vapor back into the system, which can ruin sensitive samples, skew experimental results, or contaminate a final product.

The circulating water pump uses water as its sealant and pumping medium, completely eliminating this risk and ensuring a clean vacuum.

Resilience Against Chemical Corrosion

Chemical laboratories frequently work with volatile acids, alkalis, and organic solvents.

Vapors from these substances can quickly degrade the components and oil in a traditional vacuum pump, leading to frequent maintenance and premature failure.

These pumps are specifically built with corrosion-resistant materials, making them a durable and reliable workhorse for processes like distillation and filtration of aggressive chemicals.

Efficiency in Resource-Limited Settings

Universities and research institutes often operate under tight budgets and increasing pressure for sustainable practices.

Compared to a system that uses tap water directly, a circulating pump can save over 10 tons of water in a single day by recycling its internal supply. It also consumes over 35% less electricity than many other pump types.

This dual savings on water and power makes it a highly economical and environmentally responsible choice for any lab.

Key Laboratory and Production Processes Enabled

This pump provides the necessary negative pressure for a range of fundamental scientific procedures. Understanding these applications reveals its true utility.

Phase Transition Processes

Processes like evaporation, distillation, and sublimation rely on lowering the pressure in a vessel.

Reducing the ambient pressure lowers the boiling point of liquids, allowing for gentle and rapid separation or purification of temperature-sensitive compounds without thermal degradation.

Separation and Purification

Vacuum filtration and crystallization are core techniques in chemistry and biology.

Applying a vacuum dramatically speeds up the process of pulling a liquid through a filter medium, separating a solid precipitate from its mother liquor far more efficiently than gravity alone.

Sample Preparation

Before analysis or further use, samples often need to be completely dry or free of dissolved gases.

A vacuum is used for drying to remove residual solvents at low temperatures. It is also used for degassing liquids to prevent bubble formation that can interfere with analytical instruments or subsequent reactions.

Understanding the Trade-offs

While highly effective, the circulating water vacuum pump is not a universal solution. Objectivity requires acknowledging its operational boundaries.

Not Designed for Ultra-High Vacuum

The ultimate vacuum level this pump can achieve is limited by the vapor pressure of the water in its tank.

This makes it perfect for the "rough" or "medium" vacuum needs of most lab procedures, but unsuitable for applications requiring ultra-high vacuum (UHV), such as surface science or particle accelerators.

Performance Depends on Water Temperature

Because the vacuum level is tied to water's vapor pressure, performance is affected by water temperature. Colder water will produce a deeper, more stable vacuum.

In continuous, heavy-use scenarios, the water in the tank may warm up, slightly reducing the maximum achievable vacuum. For most standard applications, this effect is negligible.

Best Suited for Lab and Pilot Scale

The design prioritizes flexibility, cleanliness, and ease of use in a laboratory or small-scale production setting.

These pumps are not intended for large, heavy-industrial manufacturing operations that require massive, continuous vacuum flow rates. Their strength lies in their adaptability for research, small trials, and batch processes.

Making the Right Choice for Your Application

To determine if this pump is the correct tool, consider your primary goal.

- If your primary focus is sample purity and avoiding contamination: The pump's oil-free design is its single most important feature, making it ideal for biochemical, pharmaceutical, and food science applications.

- If your primary focus is operational cost and sustainability: Its significant water and energy savings offer a clear and rapid return on investment, especially for academic labs or facilities in water-scarce regions.

- If your primary focus is versatility in a chemical lab: Its robust resistance to acids and solvents, combined with its mobility, makes it a flexible workhorse for a wide array of synthesis and purification tasks.

Ultimately, this pump empowers precise scientific work by providing a reliable vacuum that is clean, efficient, and cost-effective.

Summary Table:

| Industry/Application | Key Benefits |

|---|---|

| Pharmaceuticals & Biochemistry | Oil-free operation prevents contamination, ensures sample purity |

| Chemical Labs | Corrosion-resistant, handles acids and solvents for distillation and filtration |

| Food Science & Agriculture | Clean vacuum for safe processing, ideal for sensitive materials |

| Universities & Research | Saves water and energy, cost-effective and sustainable for tight budgets |

| Bioengineering | Supports degassing and drying without oil risks, maintains experimental integrity |

Ready to elevate your laboratory's performance with a clean, efficient vacuum solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements. Whether you're in pharmaceuticals, biochemistry, or chemical research, our products deliver purity, durability, and sustainability. Contact us today to discuss how we can support your specific needs and drive your innovations forward!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the function of a vacuum drying oven for biochar FTIR analysis? Ensure High-Purity Sample Preparation

- What is the function of a graphite plate in microwave cladding? Ensure Purity & Thermal Uniformity for HEA Synthesis

- What is the function of high-alumina ceramic boats? Ensure Purity in I-NC Catalyst Synthesis

- How does a laboratory blast drying oven facilitate the conversion of acid leach liquor into solid PAFS? Key Mechanism

- Why are alumina ceramic tubes preferred for high-temperature furnaces? Ensure Stability and Control Up to 1800°C

- How is the vacuuming operation performed with a water circulating vacuum pump? Master the Liquid Ring Technique

- What is the specific utility of crucibles in high-temperature lab applications? Precision & Thermal Integrity

- What is the function of high-purity alumina crucibles in NRBBO:Eu2+ sintering? Ensure Pure Phosphor Synthesis