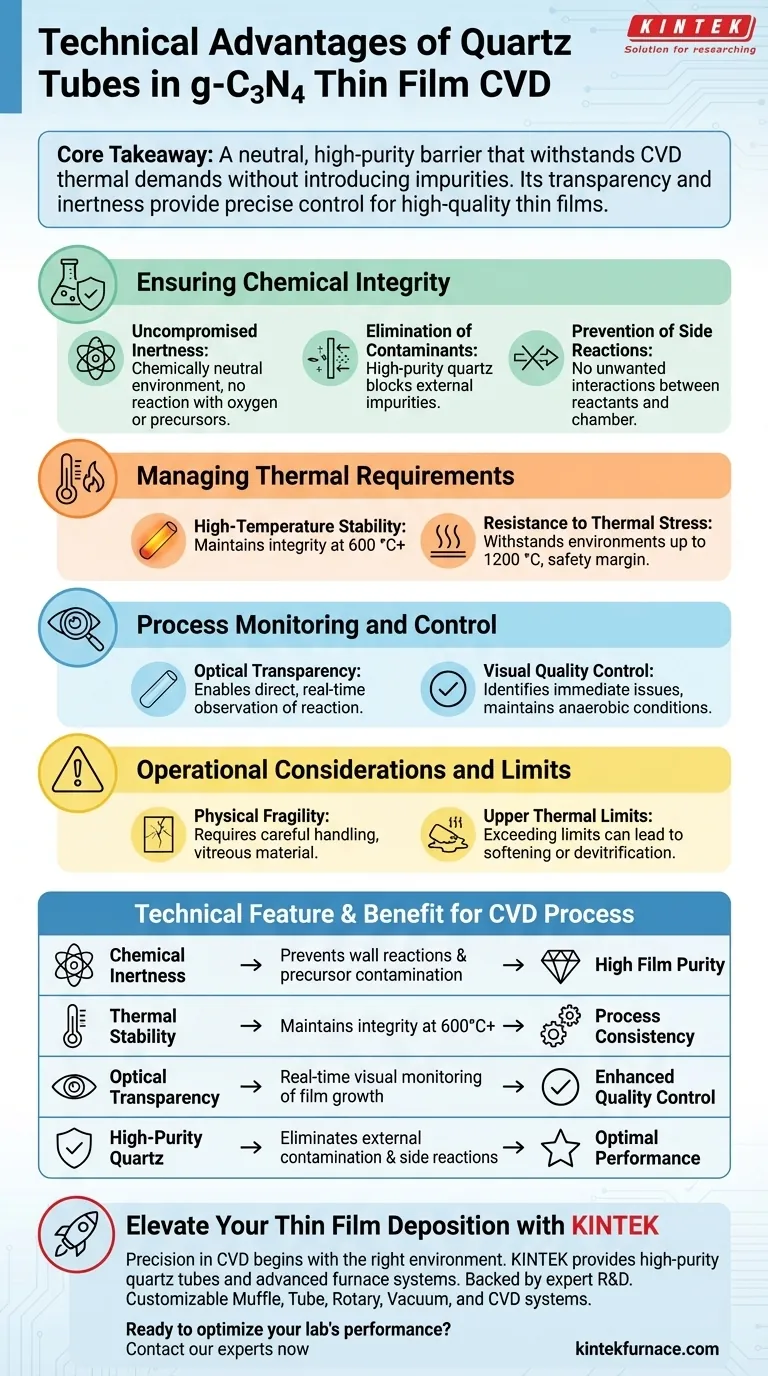

The primary technical advantages of using a quartz tube for g-C3N4 thin film CVD include superior high-temperature resistance, chemical inertness, and optical transparency. These properties ensure the reaction environment remains stable at 600 °C while preventing precursor contamination and allowing visual monitoring of the film growth.

Core Takeaway The quartz tube acts as a neutral, high-purity barrier that withstands the thermal demands of Chemical Vapor Deposition (CVD) without introducing impurities. Its transparency and inertness provide the precise control necessary for growing high-quality, uncontaminated thin films.

Ensuring Chemical Integrity

Uncompromised Chemical Inertness

A quartz tube creates an environment that is chemically neutral. It does not react with oxygen or the specific reaction precursors used in the CVD process. This prevents the tube material itself from interfering with the chemical reaction.

Elimination of Contaminants

High-purity quartz effectively prevents external contamination from entering the reaction zone. By isolating the process, it ensures that the resulting g-C3N4 thin film maintains the clean environment necessary for optimal performance.

Prevention of Side Reactions

Unlike metal furnace walls, quartz prevents unwanted side reactions between the reactants and the chamber boundaries. This ensures that the chemical precursors are consumed solely for the deposition of the target film, rather than being wasted on container interactions.

Managing Thermal Requirements

High-Temperature Stability

The CVD process for g-C3N4 requires elevated temperatures, typically around 600 °C. Quartz possesses excellent thermal stability, allowing it to maintain its structural integrity and performance characteristics consistently at these temperatures.

Resistance to Thermal Stress

Quartz tubes are capable of withstanding environments significantly hotter than the standard 600 °C requirement, with some grades managing up to 1200 °C. This provides a significant safety margin during operation, ensuring the chamber does not degrade during heating cycles.

Process Monitoring and Control

Optical Transparency

A distinct advantage of quartz over ceramic or metal chambers is its transparency. This allows operators to perform direct, real-time observation of the reaction process inside the tube.

Visual Quality Control

The ability to see into the chamber helps in identifying immediate issues with the deposition flow. It ensures that the strict anaerobic or specific atmospheric conditions are maintained without needing to open the chamber and disrupt the process.

Operational Considerations and Limits

Physical Fragility

While quartz offers exceptional thermal and chemical resistance, it remains a vitreous material. Unlike metal chambers, it requires careful handling to avoid physical breakage during loading, unloading, or cleaning procedures.

Upper Thermal Limits

Although quartz is stable at 600 °C and can withstand up to 1200 °C, exceeding these extreme upper limits can lead to softening or devitrification. Operators must ensure the CVD protocol does not inadvertently spike beyond the material's rated thermal ceiling.

Making the Right Choice for Your Goal

When selecting a reaction chamber for Chemical Vapor Deposition, align your choice with your specific technical priorities:

- If your primary focus is Film Purity: Rely on quartz for its chemical inertness to prevent wall reactions and precursor contamination.

- If your primary focus is Process Optimization: Utilize the transparency of quartz to visually monitor reaction progress and troubleshoot in real-time.

- If your primary focus is Thermal Stability: Leverage the high-temperature resistance of quartz to ensure consistent performance at 600 °C and above.

By utilizing a quartz tube, you secure a reaction environment that is both physically robust against heat and chemically invisible to your process.

Summary Table:

| Technical Feature | Benefit for g-C3N4 CVD Process | Impact on Quality |

|---|---|---|

| Chemical Inertness | Prevents reactions between precursors and tube walls | High Film Purity |

| Thermal Stability | Maintains structural integrity at 600°C+ | Process Consistency |

| Optical Transparency | Enables real-time visual monitoring of film growth | Enhanced Quality Control |

| High-Purity Quartz | Eliminates external contamination and side reactions | Optimal Performance |

Elevate Your Thin Film Deposition with KINTEK

Precision in CVD processes begins with the right environment. As a leader in laboratory high-temperature solutions, KINTEK provides high-purity quartz tubes and advanced furnace systems designed to meet the rigorous demands of g-C3N4 thin film growth.

Backed by expert R&D and world-class manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to your unique research or production needs. Ensure chemical integrity and superior thermal control for your materials today.

Ready to optimize your lab's performance? Contact our experts now to find the perfect thermal solution for your application.

Visual Guide

References

- Kota Higuchi, Yoshio Hashimoto. Layered carbon nitride films deposited under an oxygen-containing atmosphere and their electronic properties. DOI: 10.1063/5.0193419

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the preparation steps for a water circulating vacuum pump? Ensure Optimal Performance and Longevity

- Why are high-purity alumina crucibles used for phosphor synthesis? Ensure Maximum Luminescence and Spectral Purity

- How is measurement accuracy maintained for infrared pyrometers? Master Optical Hygiene for High-Temp Metallic Melts

- What is the function of a water-cooled jacket on a sampling probe? Optimize Atomization and Protect Hardware

- What is the purpose of using a high-purity ceramic crucible with a sealed lid during the thermal treatment of biochar?

- What are the advantages of using high-purity quartz tubes as reaction vessels? Unlock Active Flux Synthesis

- What are the critical functions of graphite molds in hot press sintering? Discover their role in densification

- What is the primary function of a drying oven during LLZTO preparation? Ensure Pure Phase Solid Electrolytes