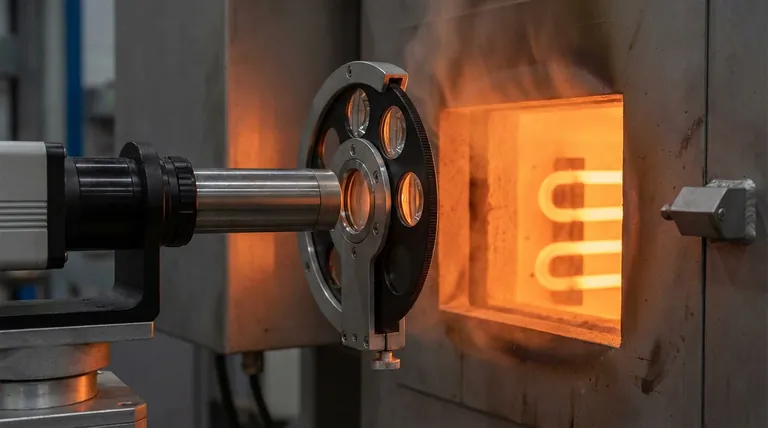

Measurement accuracy in high-temperature metallic melt processing is maintained by mechanically protecting the pyrometer’s optical path from the harsh environment. While the sensor relies on Planck’s Law to calculate temperature from infrared radiation, the physical accumulation of metallic vapors and dust on the viewport can obstruct this radiation. To prevent this "fogging" effect, advanced systems utilize a rotating protection wheel equipped with multiple lenses and mirrors to ensure a clean line of sight is available throughout experimental cycles.

The Core Insight High-temperature accuracy is less about the sensor's electronics and more about optical hygiene. Even the most precise pyrometer will fail if metallic vapors deposit on the viewport; therefore, a mechanical system that rotates fresh optical elements into place is essential for consistent, long-term data integrity.

The Challenge of High-Temperature Environments

The Threat of Vapor Deposition

In processing environments ranging from 300°C to 2400°C, the primary threat to accuracy is not heat, but particulate matter.

Metallic melts release vapors and dust that naturally rise and deposit on cooler surfaces.

If these contaminants coat the viewport, they block infrared energy. This forces the pyrometer to read a lower temperature than reality, leading to process errors.

Why Contact Sensors Fail

Maintaining accuracy is difficult because traditional alternatives, like contact thermocouples, are often unsuitable for these extremes.

In vacuum or high-current sintering environments, thermocouples suffer from electromagnetic interference (EMI), which skews readings.

Furthermore, physical probes have limited lifespans when exposed to ultra-high temperatures and reactive molten metals.

The Mechanical Solution for Accuracy

The Rotating Protection Wheel

To counteract vapor deposition, reliable systems employ a rotating protection wheel.

This mechanism houses multiple lenses and mirrors. As the process continues and one segment becomes compromised by dust or vapor, the wheel rotates to expose a fresh, clean optical element.

Preserving the Optical Path

This mechanical rotation ensures that the light path remains unobstructed.

By maintaining a clear path, the pyrometer can accurately receive infrared radiation according to Planck’s Law.

This allows for precise monitoring of the center of the mold (often graphite) through an observation hole, ensuring complex heating profiles and holding times are met without drift.

Understanding the Trade-offs

Mechanical Complexity

While a protection wheel solves the accuracy problem, it introduces moving parts into the sensing system.

Unlike a static sensor, this mechanism requires synchronization with the process cycle to ensure a fresh lens is available when critical measurements are taken.

Dependency on Line of Sight

Infrared pyrometry is strictly a non-contact, line-of-sight technology.

Accuracy is entirely dependent on the alignment of the viewport and the observation hole.

If the internal observation hole in the mold shifts or becomes physically blocked by debris that the protection wheel cannot reach, the measurement will fail regardless of the sensor's calibration.

Making the Right Choice for Your Goal

To achieve consistent results in metallic melt processing, consider how you prioritize sensor longevity versus immediate data precision.

- If your primary focus is Long-Duration Cycles: Prioritize systems with a high-capacity protection wheel to ensure you do not run out of clean optical elements before the process finishes.

- If your primary focus is Electromagnetic Immunity: Rely on non-contact pyrometers over thermocouples to eliminate noise from high-current heating elements.

Accuracy in pyrometry is not just about measuring light; it is about guaranteeing the path for that light remains clear.

Summary Table:

| Factor | Impact on Accuracy | Solution |

|---|---|---|

| Vapor Deposition | Blocks IR radiation; causes temperature under-readings | Rotating protection wheel with fresh lenses |

| EMI Interference | Skews electronic signals in thermocouples | Non-contact pyrometry (electromagnetic immunity) |

| Optical Path | Physical obstructions lead to total measurement failure | Clean line-of-sight & aligned observation holes |

| Extreme Heat | Degrades physical probes and contact sensors | High-temp non-contact monitoring (Planck's Law) |

Precision Heat Processing Starts with KINTEK

Don’t let vapor deposition or electromagnetic interference compromise your data integrity. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temperature furnaces are fully customizable to meet your unique processing needs.

Ready to optimize your high-temperature accuracy? Contact us today to discuss your custom furnace requirements.

References

- G. Lohöfer, Andreas Meyer. TEMPUS—A microgravity electromagnetic levitation facility for parabolic flights. DOI: 10.1063/5.0182719

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the components of the circulating water vacuum pump and their functions? Discover Oil-Free Vacuum Solutions

- How are quartz tubes used in laboratory applications? Essential for High-Temp, High-Purity Processes

- Alumina vs. Platinum Crucibles for Lithium Titanate (LTO) Synthesis: Which is Right for You?

- How do graphite molds in SPS affect maraging steel? Managing Carbon Diffusion for Precise Sintering Results

- How does a laboratory blast drying oven facilitate the treatment of Au/ZnO/In2O3 precursor precipitates? Key Benefits

- What is the function of laboratory pellet presses and steel dies? Maximize Reaction Kinetics in Oxide Processing

- Why is a graphite crucible used and the melt temperature maintained at 750°C for AA7150-Al2O3? Optimize Your Composite

- What processes is the circulating water multifunctional vacuum pump suitable for? Ideal for Clean, Economical Lab Vacuum Needs