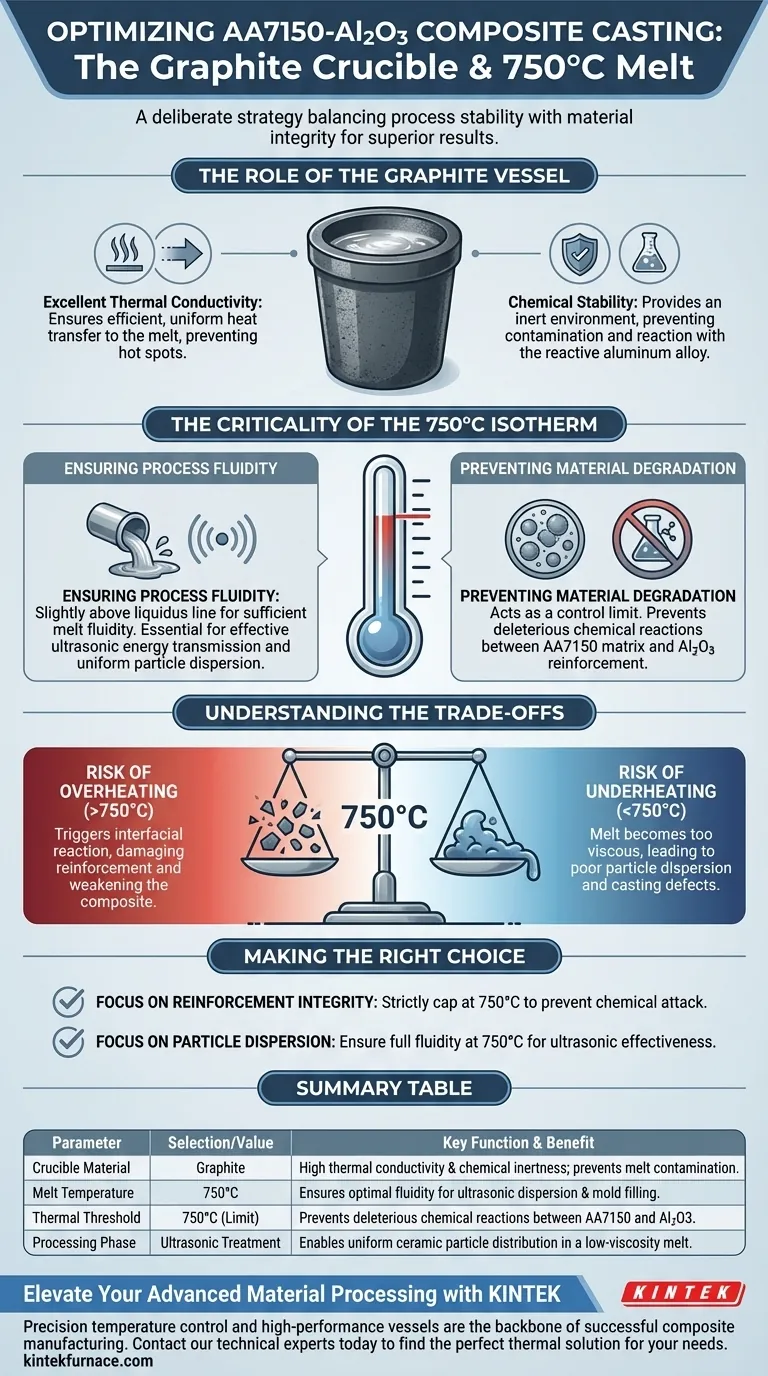

The selection of a graphite crucible and a specific 750°C holding temperature is a deliberate strategy to balance process stability with material integrity. Graphite provides a chemically inert, highly conductive vessel, while the precise temperature ensures the AA7150 aluminum alloy is fluid enough for ultrasonic processing and casting without becoming so hot that it chemically degrades the Al2O3 reinforcement.

Success in casting AA7150-Al2O3 composites relies on maintaining a strict thermal window. 750°C is the critical threshold that permits effective ultrasonic dispersion and casting flow while preventing adverse chemical reactions between the metal matrix and the ceramic reinforcement.

The Role of the Graphite Vessel

Thermal Conductivity and Resistance

Graphite is chosen primarily for its excellent thermal conductivity. This property ensures that heat is transferred efficiently and uniformly to the melt, preventing hot spots or uneven temperature gradients.

Additionally, graphite possesses high high-temperature resistance, allowing it to maintain structural integrity under the intense thermal loads required for melting aluminum alloys.

Chemical Stability

The crucible must not contaminate the alloy. Graphite provides a stable chemical environment for the melt.

This inertness prevents the vessel itself from reacting with the reactive aluminum alloy, ensuring the final composite maintains the intended chemical composition.

The Criticality of the 750°C Isotherm

Ensuring Process Fluidity

The melt is maintained at 750°C because this temperature is slightly above the liquidus line of the alloy.

At this temperature, the metal achieves sufficient melt fluidity. This low viscosity is essential for the effective transmission of ultrasonic energy during the dispersion phase, ensuring the Al2O3 particles are distributed evenly.

Fluidity is also critical for the subsequent mold casting, allowing the metal to fill the mold intricacies before solidifying.

Preventing Material Degradation

While high heat improves flow, excessive heat is dangerous to the composite's quality.

Holding the temperature at 750°C acts as a control limit to prevent deleterious chemical reactions.

If the temperature rises significantly higher, the matrix (AA7150) may react chemically with the reinforcement phase (Al2O3). This degrades the reinforcement and compromises the mechanical properties of the final composite.

Understanding the Trade-offs

The Risk of Overheating

Exceeding 750°C shifts the balance from fluidity to reactivity.

While the metal may flow better, you risk triggering an interfacial reaction between the aluminum and the alumina. This damages the reinforcement phase, rendering the composite weaker despite the better fill.

The Risk of Underheating

Dropping significantly below 750°C risks crossing the liquidus line too early.

If the melt is too viscous, ultrasonic energy transmission becomes inefficient, leading to poor particle dispersion. Furthermore, the metal may freeze prematurely during casting, causing defects.

Making the Right Choice for Your Goal

To ensure the production of a high-quality AA7150-Al2O3 composite, adhere to these operational principles:

- If your primary focus is Reinforcement Integrity: Strictly cap your temperature at 750°C to prevent the matrix from chemically attacking the Al2O3 particles.

- If your primary focus is Particle Dispersion: Ensure the melt remains fully fluid (at 750°C) to allow ultrasonic energy to effectively break up agglomerates.

By using a graphite vessel and locking the temperature at 750°C, you maintain the narrow window required for both excellent castability and superior material properties.

Summary Table:

| Parameter | Selection/Value | Key Function & Benefit |

|---|---|---|

| Crucible Material | Graphite | High thermal conductivity & chemical inertness; prevents melt contamination. |

| Melt Temperature | 750°C | Ensures optimal fluidity for ultrasonic dispersion & mold filling. |

| Thermal Threshold | 750°C (Limit) | Prevents deleterious chemical reactions between AA7150 and Al2O3. |

| Processing Phase | Ultrasonic Treatment | Enables uniform ceramic particle distribution in a low-viscosity melt. |

Elevate Your Advanced Material Processing with KINTEK

Precision temperature control and high-performance vessels are the backbone of successful composite manufacturing. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique AA7150-Al2O3 or metal-matrix composite needs.

Ready to achieve superior material integrity and process stability?

Contact our technical experts today to find the perfect thermal solution for your laboratory or production line.

Visual Guide

References

- K. Chinna Maddaiah, R. Pramod. Studies on the Mechanical, Strengthening Mechanisms and Tribological Characteristics of AA7150-Al2O3 Nano-Metal Matrix Composites. DOI: 10.3390/jcs8030097

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role do substrate heaters play in Ga2O3:Er thin films? Unlock Crystalline Beta-Phase Transitions

- Why is laboratory heating equipment critical for photothermal actuators? Master Structural Curing & Precision Thermal Control

- What is the significance of using a vacuum saturation device for AAS concrete? Ensure Valid Chloride Ion Testing

- Why is a high-precision mass flow controller (MFC) necessary in ferronickel alloy smelting? Ensure Metal Purity

- What is the purpose of a PTFE-lined autoclave in TiO2 synthesis? Unlock Precision Nano-material Growth

- Why is radiation correction necessary for K-type thermocouple readings? Ensure Accurate High-Temp Combustion Data

- What is the specific purpose of using a graphite crucible equipped with a plug during the melting process of Mg3Sb2?

- How does the design of a graphite box optimize the sulfurization of Sb thin films? Key Insights for Film Uniformity