Laboratory drying and constant-temperature heating equipment serve as the critical foundation for structural integrity in photothermal actuator fabrication. These devices perform two essential functions simultaneously: they drive the controlled, slow evaporation of solvents like ethanol and provide the precise thermal environment required to cure epoxy resins. Without this controlled heating, the device would lack the mechanical strength necessary for operation.

The success of a photothermal actuator relies on transforming liquid chemical components into a solid, unified structure. Precise thermal control is the catalyst that locks carbon nanospheres to the substrate, ensuring the device is both durable and hydrophobic.

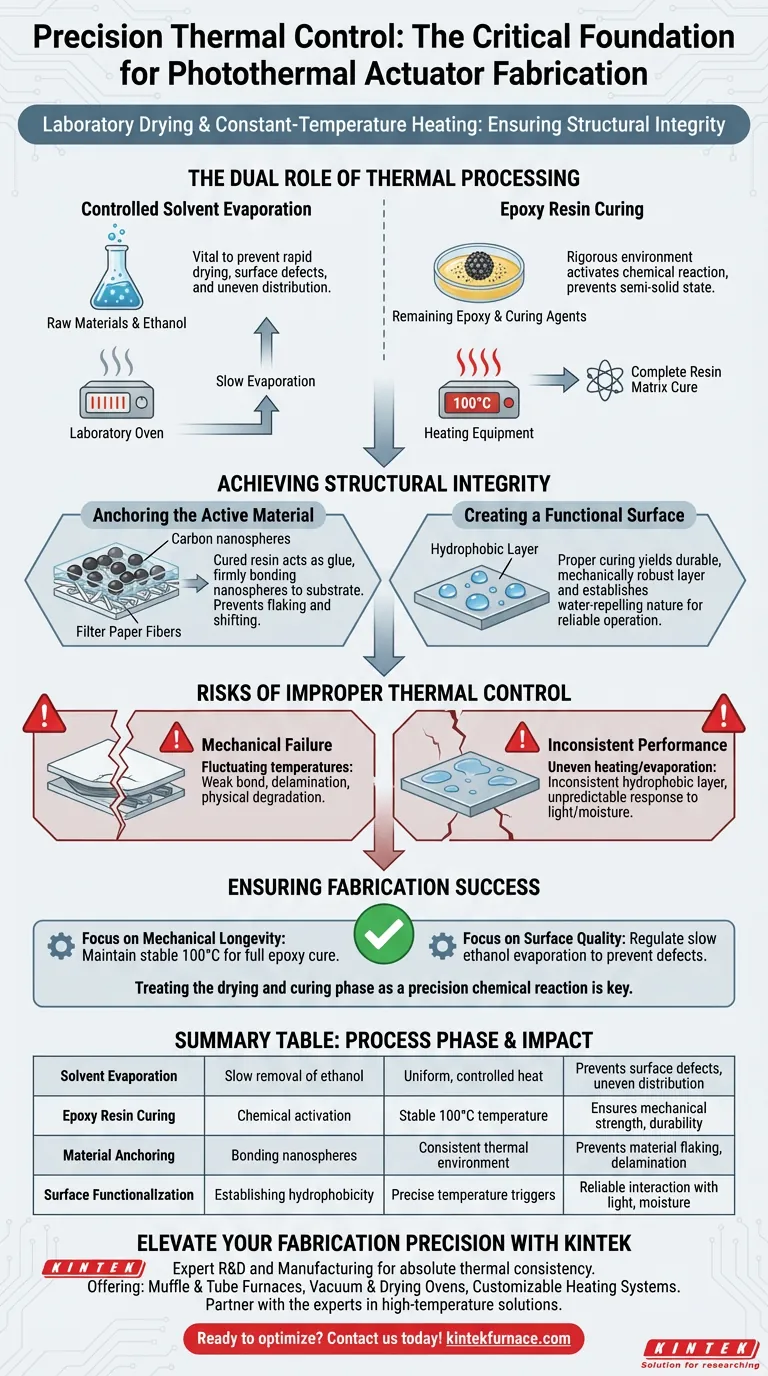

The Dual Role of Thermal Processing

Controlled Solvent Evaporation

In the initial stages of fabrication, the raw materials are often suspended in solvents such as ethanol.

Laboratory ovens are used to drive the slow evaporation of these solvents.

This controlled removal is vital to prevent rapid drying, which could lead to surface defects or uneven material distribution.

Epoxy Resin Curing

Once the solvent is removed, the remaining epoxy resins and curing agents require a specific thermal trigger to activate.

The heating equipment maintains a rigorous environment—typically around 100°C—to facilitate this chemical reaction.

This specific temperature ensures the resin matrix cures completely rather than remaining in a semi-solid or tacky state.

Achieving Structural Integrity

Anchoring the Active Material

The primary goal of the thermal curing process is to create a robust mechanical bond.

The cured resin acts as a glue, firmly anchoring carbon nanospheres to the fibers of the filter paper substrate.

This prevents the active photothermal material from flaking off or shifting during the actuator's movement.

Creating a Functional Surface

Beyond holding the materials together, the heating process dictates the surface properties of the actuator.

Properly cured resin results in a mechanically durable layer that can withstand repeated use.

Additionally, this process is responsible for establishing the hydrophobic (water-repelling) nature of the photothermal layer, which is often critical for the device's interaction with its environment.

Risks of Improper Thermal Control

Mechanical Failure

If the curing temperature fluctuates or fails to reach the required 100°C target, the resin matrix will not form a strong network.

This results in a weak bond between the carbon nanospheres and the filter paper fibers.

Under these conditions, the actuator is likely to suffer from delamination or physical degradation during operation.

Inconsistent Performance

If the solvent evaporation is not controlled or if the heating is uneven, the hydrophobic layer may develop inconsistencies.

This can lead to unpredictable responses to light or moisture, compromising the precision of the actuator.

Ensuring Fabrication Success

To maximize the performance of your photothermal actuators, prioritize precision in your thermal processing steps.

- If your primary focus is mechanical longevity: Ensure your equipment can maintain a stable 100°C to fully cure the epoxy resin matrix and anchor the nanospheres.

- If your primary focus is surface quality: Utilize the equipment to regulate the slow evaporation of ethanol, preventing defects caused by rapid drying.

Treating the drying and curing phase as a precision chemical reaction rather than a simple drying step is the key to producing reliable, high-performance actuators.

Summary Table:

| Process Phase | Primary Function | Key Requirement | Impact on Final Device |

|---|---|---|---|

| Solvent Evaporation | Slow removal of ethanol | Uniform, controlled heat | Prevents surface defects and uneven distribution |

| Epoxy Resin Curing | Chemical activation of resin matrix | Stable 100°C temperature | Ensures mechanical strength and durability |

| Material Anchoring | Bonding nanospheres to substrate | Consistent thermal environment | Prevents material flaking and delamination |

| Surface Functionalization | Establishing hydrophobicity | Precise temperature triggers | Reliable interaction with light and moisture |

Elevate Your Fabrication Precision with KINTEK

Successful photothermal actuator development hinges on absolute thermal consistency. At KINTEK, we understand that even a minor temperature fluctuation can compromise your device's structural integrity and performance.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of laboratory equipment including:

- Muffle & Tube Furnaces for high-temperature material synthesis.

- Vacuum & Drying Ovens for precise solvent evaporation and epoxy curing.

- Customizable Heating Systems tailored to your specific lab-scale or industrial needs.

Ensure your actuators achieve maximum mechanical longevity and functional reliability. Partner with the experts who specialize in precision high-temperature solutions for researchers and manufacturers alike.

Ready to optimize your fabrication process? Contact us today to find your custom furnace solution!

Visual Guide

References

- Mingshan Wen, Fuquan Xiong. Photothermal Performance of Lignin-Based Nanospheres and Their Applications in Water Surface Actuators. DOI: 10.3390/polym16070927

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the integration of digital control panels and safety devices enhance industrial electric furnace operation?

- How do dense-walled crucibles function during the high-temperature melting of bismuth-lead-borosilicate glass?

- What type of motor does the circulating water multifunctional vacuum pump use? Discover Its Oil-Free Benefits

- Why are high-purity quartz tubes and quartz boats preferred for plastic pyrolysis? Ensure Precise, Pure Results

- What are the key properties of alumina ceramic furnace tubes? Discover Their High-Temp and Chemical Resistance

- How are quartz tubes applied in optics and pharmaceuticals? Unlock Purity and Performance in Critical Applications

- Why is a standard Quartz Crystal Sensor required during germanium evaporation for nanocrystal fabrication?

- Why are laboratory precision stirrers and heating devices essential for synthesizing magnetic precursor solutions?