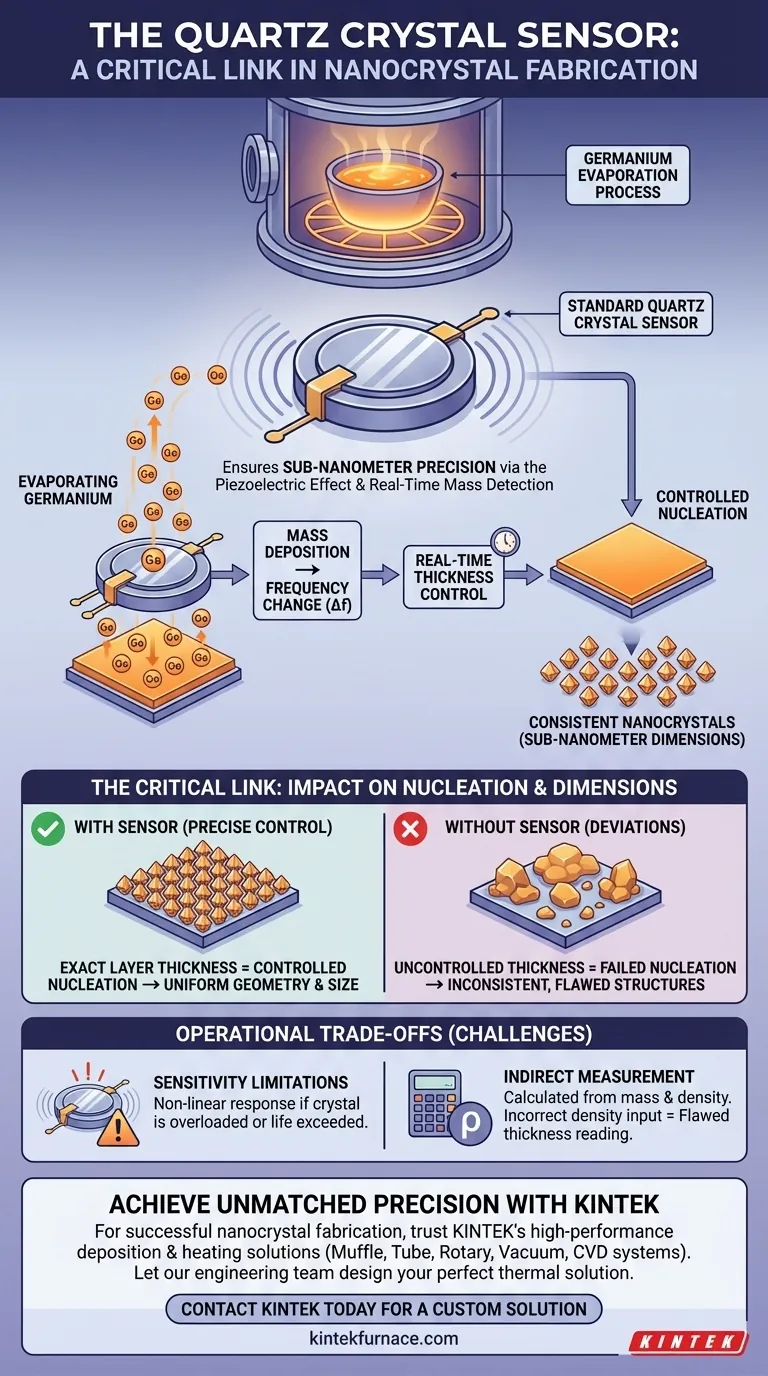

A standard Quartz Crystal Sensor is the primary mechanism for ensuring sub-nanometer precision during the germanium evaporation process. By leveraging the piezoelectric effect, this device detects minute changes in deposited mass in real-time. This capability allows for exact control over the thickness of the evaporated layer, which is the foundational variable in defining the final properties of the nanocrystals.

In nanocrystal fabrication, the thickness of the deposited material directly dictates the nucleation process. The Quartz Crystal Sensor acts as the critical feedback loop, translating mass changes into precise thickness measurements to ensure the dimensions of the final product meet strict specifications.

The Mechanics of Precision Control

Utilizing the Piezoelectric Effect

The sensor operates by exploiting the piezoelectric effect. This physical phenomenon allows the sensor to translate mechanical stress—in this case, the weight of the depositing material—into a measurable electrical signal.

Real-Time Mass Detection

As germanium evaporates and lands on the sensor, the added mass alters the crystal's oscillation frequency.

Because this detection happens in real-time, engineers can monitor the rate of deposition instantly. This prevents the need for post-process measurements, which are often too late to correct errors.

The Critical Link to Nanocrystal Formation

Impact on Nucleation

The primary reference indicates that the fabrication of nanocrystals is highly sensitive to the initial layer thickness.

Even minor deviations in the amount of germanium deposited can fundamentally alter the nucleation process. Nucleation is the "seed" stage where the crystal begins to form; if this stage is uncontrolled, the entire structure may fail.

Achieving Sub-Nanometer Dimensions

To achieve specific nanocrystal dimensions, the margin for error is virtually non-existent.

The Quartz Crystal Sensor provides sub-nanometer precision, ensuring that the evaporated layer is exactly as thick as required to support the desired crystal geometry. Without this level of granularity, achieving consistent nanocrystal sizes is impossible.

Understanding the Operational Trade-offs

Sensitivity Limitations

While the sensor provides high precision, it relies entirely on the accuracy of the mass detection. If the sensor becomes overloaded or the "crystal life" is exceeded, the frequency response may become non-linear, leading to inaccurate thickness readings.

Indirect Measurement

It is important to remember that the sensor measures mass, not physical thickness directly.

The system calculates thickness based on the density of germanium. If the density parameters entered into the controller are incorrect, or if the material density changes during deposition, the resulting thickness reading will be flawed despite the sensor working correctly.

Ensuring Process Integrity

To maximize the effectiveness of the Quartz Crystal Sensor in your fabrication workflow, consider the following focus areas:

- If your primary focus is Dimensional Uniformity: Rely on the sensor’s sub-nanometer precision to maintain strict consistency across different fabrication runs.

- If your primary focus is Process Stability: Monitor the real-time feedback loop to instantly identify and correct any deviations in the evaporation rate before they affect nucleation.

Precise control of the germanium layer is the single most important factor in transitioning from raw material to functional nanocrystal.

Summary Table:

| Feature | Function in Germanium Evaporation | Impact on Nanocrystals |

|---|---|---|

| Piezoelectric Effect | Translates mass changes into electrical signals | Enables sub-nanometer thickness control |

| Real-Time Monitoring | Detects mass deposition during evaporation | Allows immediate adjustments to nucleation |

| Frequency Response | Measures oscillation changes | Ensures consistent crystal geometry and size |

| Feedback Loop | Provides continuous rate data | Prevents deviations in structural integrity |

Achieve Unmatched Precision in Your Nanotechnology Research

Precision is the difference between a successful experiment and a failed nucleation process. KINTEK provides the high-performance deposition and heating environments necessary for advanced nanocrystal fabrication. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your specific germanium evaporation and material science requirements.

Don't let minor deviations compromise your results. Let our engineering team help you design the perfect thermal solution for your lab.

Contact KINTEK Today for a Custom Solution

Visual Guide

References

- Z. Remeš, Oleg Babčenko. Thin Hydrogenated Amorphous Silicon Carbide Layers with Embedded Ge Nanocrystals. DOI: 10.3390/nano15030176

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-alumina powder crucible? Ensure Purity in Maraging Steel Pre-treatment

- How does a Mass Flow Controller (MFC) regulate TCNF morphology? Achieve Precise Carbon Nanofiber Growth

- What is the role of High-Strength Graphite Molds in Al-Ti-Zr sintering? Mastering Vacuum Hot Pressing Performance

- How does a high-performance temperature controller contribute to repeatability? Precision for FTO Thin Film Annealing

- Why are alumina (Al2O3) sample pans or crucibles essential for DSC testing of titanium alloys? Expert Insights

- What role does a mass flow controller (MFC) play in plasma-based aluminum reduction? Precision Control for High Yields

- How do industrial sealing clamps and O-ring systems ensure process repeatability? Achieve Consistent Sintering Quality

- What creates the pumping action in a circulating water vacuum pump? Discover the Liquid Ring Mechanism