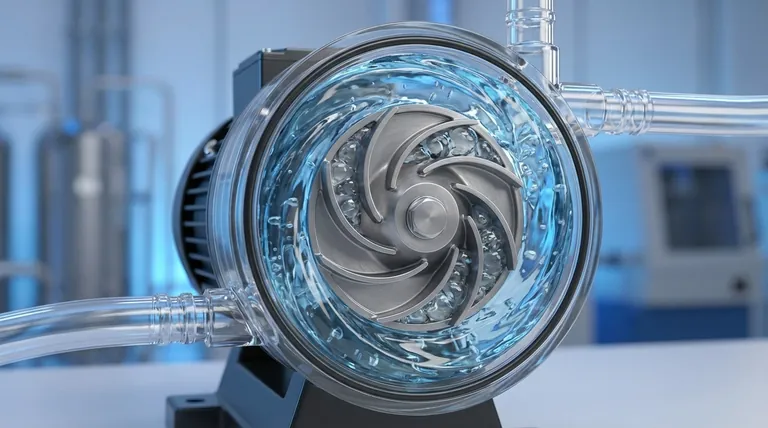

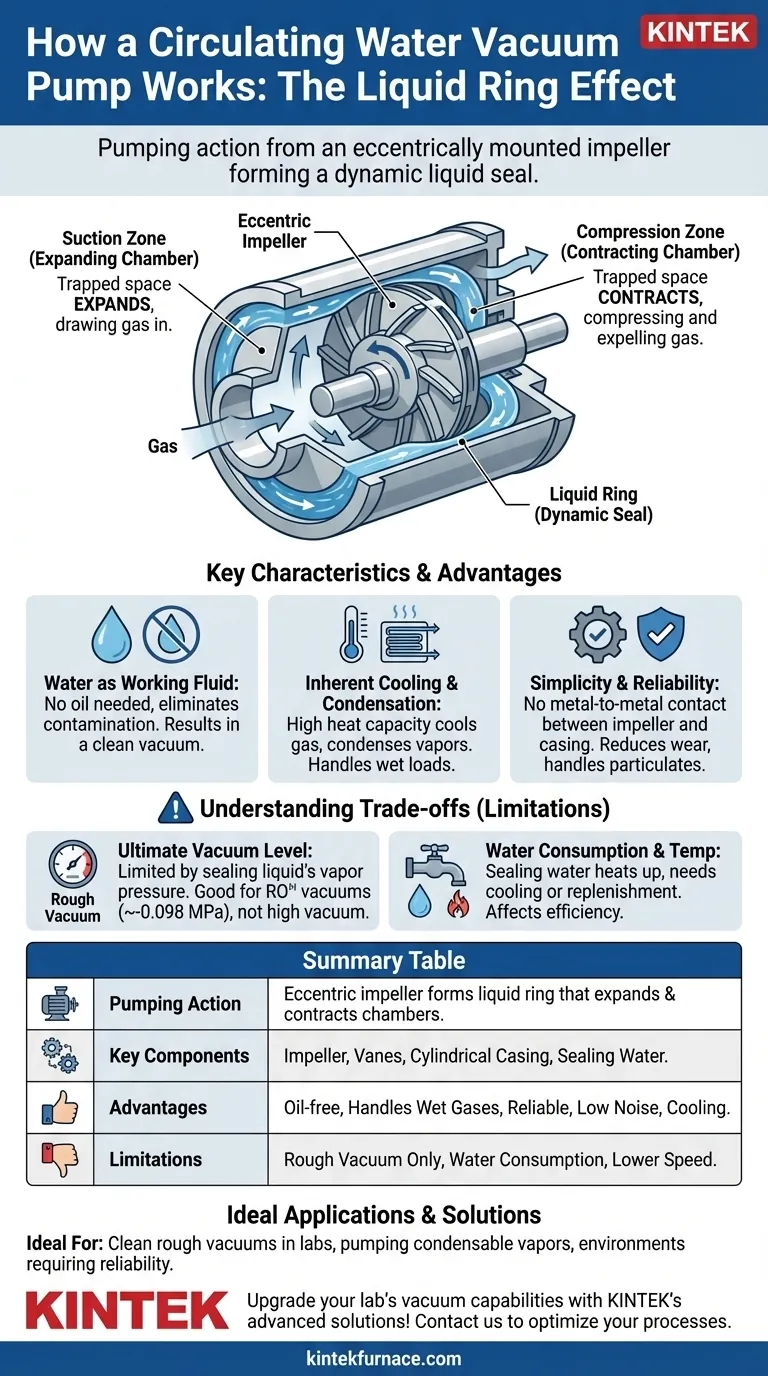

The pumping action in a circulating water vacuum pump is created by an eccentrically mounted impeller that spins inside a cylindrical casing. This offset rotation slings the sealing water outwards, forming a moving ring of liquid that cyclically expands and contracts the space between the impeller's vanes. This action traps, compresses, and expels gas, functioning like a series of liquid pistons to create a vacuum.

The core principle is not about pumping water through a jet, but about using a rotating ring of water as a dynamic seal. The key is the eccentric (off-center) placement of the impeller, which forces the volume of the chambers between its vanes to constantly change, creating the pressure difference needed for suction and exhaust.

How a Liquid Ring Creates a Vacuum

To understand the pump's action, we must visualize how the internal parts interact with the water. The design is elegantly simple, relying on physics rather than complex, tight-tolerance seals.

The Role of the Eccentric Impeller

The impeller, a wheel with multiple vanes, is the only major moving part. Crucially, it is not mounted in the center of the pump's circular housing but is offset to one side. This geometric arrangement is the foundation of its operation.

Forming the Liquid Ring

As the impeller spins, centrifugal force throws the working fluid—usually water—outward against the inner wall of the pump casing. At sufficient speed, this water forms a stable, concentric ring that rotates with the impeller.

The "Liquid Piston" Effect

Because the impeller is mounted eccentrically, the tips of its vanes are closer to the liquid ring on one side and farther away on the other. As the impeller rotates, the space between any two vanes and the inner surface of the liquid ring constantly changes.

This trapped space expands as it moves away from the point of closest approach, creating a low-pressure zone that draws gas in through the intake port. This is the suction stroke.

As it continues to rotate, the space contracts, compressing the trapped gas. This is the compression stroke. Finally, the compressed gas is expelled through the exhaust port. This cycle happens continuously for each chamber between the vanes.

Key Characteristics of this Design

This unique pumping mechanism results in several distinct operational advantages and characteristics.

The Working Fluid is Water

The pump uses water (or another compatible liquid) as its working fluid. This liquid simultaneously acts as the sealant, the pumping medium, and a coolant. The primary benefit is that it requires no oil, eliminating the risk of oil vapor back-streaming and contaminating the vacuum system. This results in a "clean" vacuum.

Inherent Cooling and Condensation

The large volume of circulating water has a high heat capacity. It effectively cools the incoming gas stream and can condense any vapors present, such as water vapor. This can increase the pumping efficiency for wet gas loads where other pumps might struggle.

Simplicity and Reliability

The design is mechanically simple, with no metal-to-metal contact between the impeller and the casing. This reduces wear, increases reliability, and allows the pump to handle small particulates or liquid slugs that would damage other vacuum pump types.

Understanding the Trade-offs

While effective, the liquid ring design is not universally optimal. Its principles come with inherent limitations.

Ultimate Vacuum Level

Liquid ring pumps are generally used for creating rough vacuums. The ultimate vacuum they can achieve is limited by the vapor pressure of the sealing liquid. As the reference notes, a typical ultimate vacuum is around -0.098 MPa (2 kPa), which is insufficient for high-vacuum or ultra-high-vacuum applications.

Water Consumption and Temperature

The sealing water can heat up during operation due to the energy of compressing the gas. This increases the water's vapor pressure, which in turn degrades the ultimate vacuum. Therefore, the water often needs to be cooled or constantly replenished, leading to water consumption.

Lower Pumping Speed

Compared to oil-sealed rotary vane pumps or dry scroll pumps of a similar size, liquid ring pumps can have lower pumping speeds and may be less energy-efficient for achieving the same level of vacuum.

Making the Right Choice for Your Application

Selecting a vacuum pump requires matching its capabilities to your specific goal.

- If your primary focus is a clean, rough vacuum for a lab environment: This pump is an excellent choice due to its oil-free operation, low noise, and reliability.

- If your primary focus is pumping wet gases or condensable vapors: The liquid ring design is superior, as it can handle vapor loads that would contaminate or damage other pump types.

- If your primary focus is achieving a deep or high vacuum (below 1 Pa): This pump is not the correct tool; you should consider a rotary vane, turbomolecular, or cryogenic pump instead.

Ultimately, understanding the elegantly simple mechanism of the liquid ring pump empowers you to use it where its strengths will shine.

Summary Table:

| Aspect | Description |

|---|---|

| Pumping Action | Eccentric impeller spins, forming a liquid ring that expands and contracts chambers to trap, compress, and expel gas. |

| Key Components | Impeller with vanes, cylindrical casing, sealing water. |

| Advantages | Oil-free operation, handles wet gases, reliable, low noise, inherent cooling. |

| Limitations | Limited to rough vacuum (e.g., -0.098 MPa), water consumption, lower pumping speed. |

| Ideal Applications | Clean rough vacuums in labs, pumping condensable vapors, environments requiring reliability. |

Upgrade your lab's vacuum capabilities with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization ensures precise fit for your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our products can optimize your processes!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Can alumina ceramic furnace tubes be customized for specific applications? Enhance Your High-Temperature Processes

- What is the function of high-purity refractory dies in slip-casting? Key Benefits for Precision Ceramic Molding

- Why is Internal Radiation Baffle (IRB) technology used in mold designs? Enhance Directional Solidification Quality

- What is the specific significance of using high-purity corundum crucibles in oxidation weight gain experiments?

- What are the key properties of alumina ceramic tubes? Unlock High-Temp Performance for Your Lab

- Why are high-alumina crucibles required for static immersion corrosion tests? Ensure Data Purity at 1000°C

- How to improve vacuum pump performance? Maximize efficiency and reach deeper vacuum levels

- What types of trays are compatible with MoSi2 heating elements? Ensure Optimal Performance and Longevity