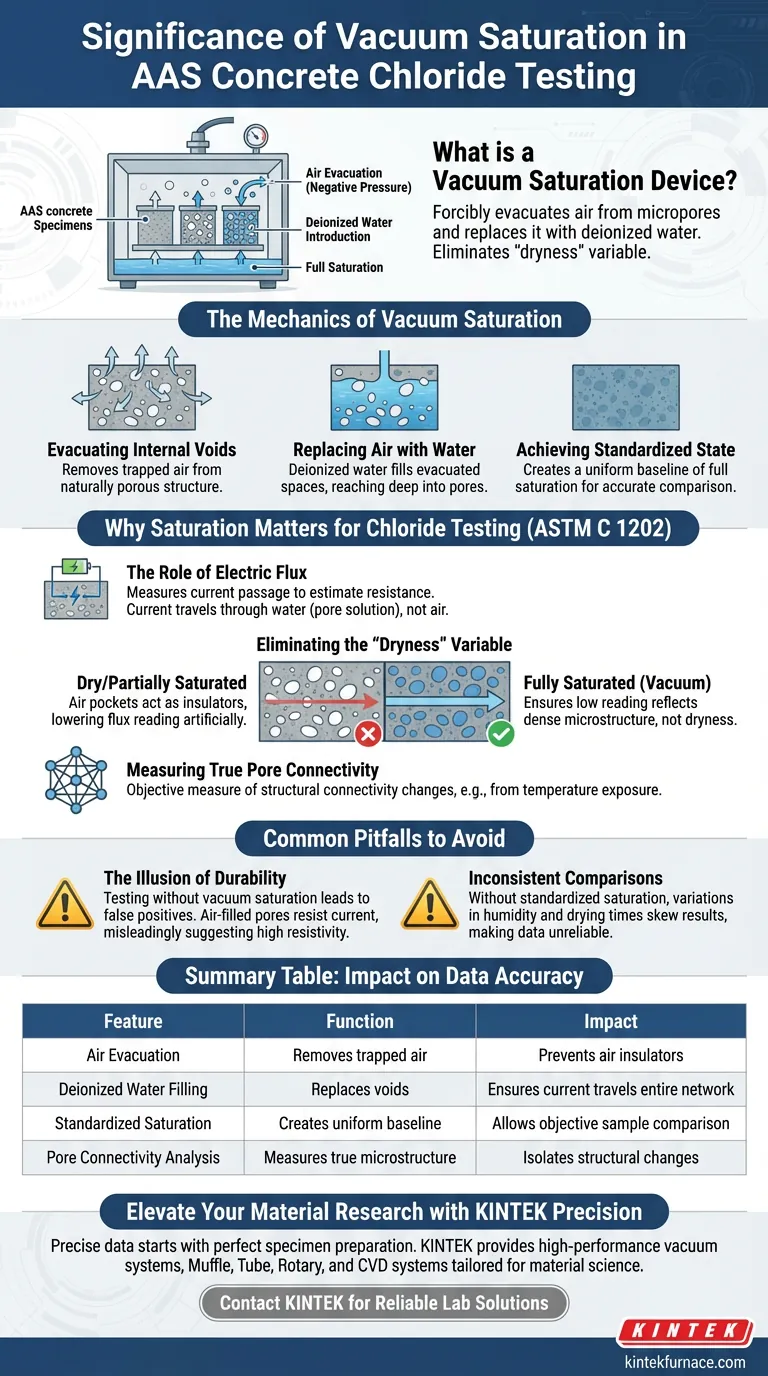

The use of a vacuum saturation device is a fundamental prerequisite for ensuring the validity of chloride ion penetration tests on Alkali-Activated Slag (AAS) concrete. This device functions by forcibly evacuating air from the concrete's internal micropores and replacing it with deionized water to achieve a state of full saturation. This step is essential to eliminate the variable of "dryness," ensuring that test results accurately reflect the physical structure of the material rather than its moisture content.

By standardizing the internal moisture conditions, vacuum saturation ensures that the electric flux measured during testing objectively reflects the connectivity of the concrete's pore structure, specifically isolating changes caused by factors like temperature exposure.

The Mechanics of Vacuum Saturation

Evacuating Internal Voids

Concrete is naturally porous, containing a network of microscopic voids that trap air.

A vacuum saturation device creates a negative pressure environment that pulls this trapped air out of the internal micropores.

Replacing Air with Water

Once the air is evacuated, the device introduces deionized water into the chamber.

Because the voids are now a vacuum, the water is drawn deep into the pore structure, filling spaces that surface soaking alone could never reach.

Achieving a Standardized State

The ultimate goal is to bring the AAS concrete specimen to a state of "full saturation."

This creates a baseline condition where every pore capable of holding water is filled, removing the initial moisture state of the sample as a variable in the experiment.

Why Saturation Matters for Chloride Testing

The Role of Electric Flux

The ASTM C 1202 test measures the passage of electrical current (electric flux) through the concrete to estimate resistance to chloride penetration.

Current travels primarily through the pore solution (water) within the concrete; it cannot travel effectively through air pockets.

Eliminating the "Dryness" Variable

If a specimen is dry or only partially saturated, air pockets will act as insulators, artificially lowering the electric flux reading.

Vacuum saturation removes this influence, ensuring that a low reading represents a dense microstructure, not simply a dry sample.

Measuring True Pore Connectivity

For AAS concrete, particularly after exposure to different temperature levels, the connectivity of pores changes.

Fully saturating the pores ensures that the test measures these structural connectivity changes objectively, providing accurate data on how temperature affects the material's durability.

Common Pitfalls to Avoid

The Illusion of Durability

Testing a specimen without vacuum saturation often leads to false positives regarding durability.

Air-filled pores resist current flow, which can mislead researchers into believing the concrete has high resistivity when it is actually just unsaturated.

Inconsistent Comparisons

Without a standardized saturation protocol, it is impossible to compare different concrete mixes or treatment groups accurately.

Variations in ambient humidity or drying times would skew results, making the data regarding pore connectivity unreliable.

Ensuring Accurate Experimental Results

To derive meaningful data from your AAS concrete experiments, apply the following guidelines based on your specific research objectives:

- If your primary focus is material characterization: Ensure full vacuum saturation to confirm that electric flux readings correspond strictly to pore connectivity and geometry.

- If your primary focus is studying temperature effects: Use vacuum saturation to normalize moisture content, allowing you to isolate the specific structural damage or changes induced by thermal exposure.

Vacuum saturation turns a variable, moisture-dependent test into a reliable metric of physical microstructure.

Summary Table:

| Feature | Function in AAS Concrete Testing | Impact on Data Accuracy |

|---|---|---|

| Air Evacuation | Removes trapped air from internal micropores | Prevents air pockets from acting as electrical insulators |

| Deionized Water Filling | Replaces voids with conductive medium | Ensures electrical current travels through the entire pore network |

| Standardized Saturation | Creates a uniform baseline moisture state | Allows objective comparison between different material samples |

| Pore Connectivity Analysis | Measures true physical microstructure | Isolates structural changes caused by temperature or mix design |

Elevate Your Material Research with KINTEK Precision

Precise data in chloride penetration experiments starts with perfect specimen preparation. KINTEK provides high-performance vacuum systems and laboratory equipment designed to meet the rigorous standards of material science. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temp furnaces—all customizable to your unique research needs.

Don't let inconsistent saturation compromise your results. Partner with KINTEK for reliable, industry-leading lab solutions tailored for researchers and concrete specialists. Contact us today to optimize your lab setup!

Visual Guide

References

- Baomeng Zhou, Ping Li. Chloride Permeability of Alkali-Activated Slag Concretes after Exposure to High Temperatures. DOI: 10.3390/ma17051028

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What are the common uses for Alumina ceramic tubes? Ideal for High-Temp, Insulation, and Corrosion Resistance

- Why is a heat-resistant crucible indispensable for magnesium purification? Ensuring Purity and Efficiency in Vacuum Sublimation

- Why is a vacuum pumping system essential for DD6 alloy and ceramic shell experiments? Achieve High-Purity Results

- What role do mass flow controllers play in gasification? Achieve Precise Atmosphere Control in Lab Furnaces

- What is the technical objective of using vacuum-sealed quartz capsules for Co-Ti-V alloy homogenization? Safeguard Chemical Integrity

- What is the sucking rate for a single tap on the water circulating vacuum pump? Get Key Specs for Your Lab

- How does a high-precision laboratory hydraulic press ensure structural consistency? Mastering Ceramic Green Bodies

- What is the role of a quartz reactor within a vacuum distillation apparatus for metal recovery? Unlocking Efficient High-Purity Extraction