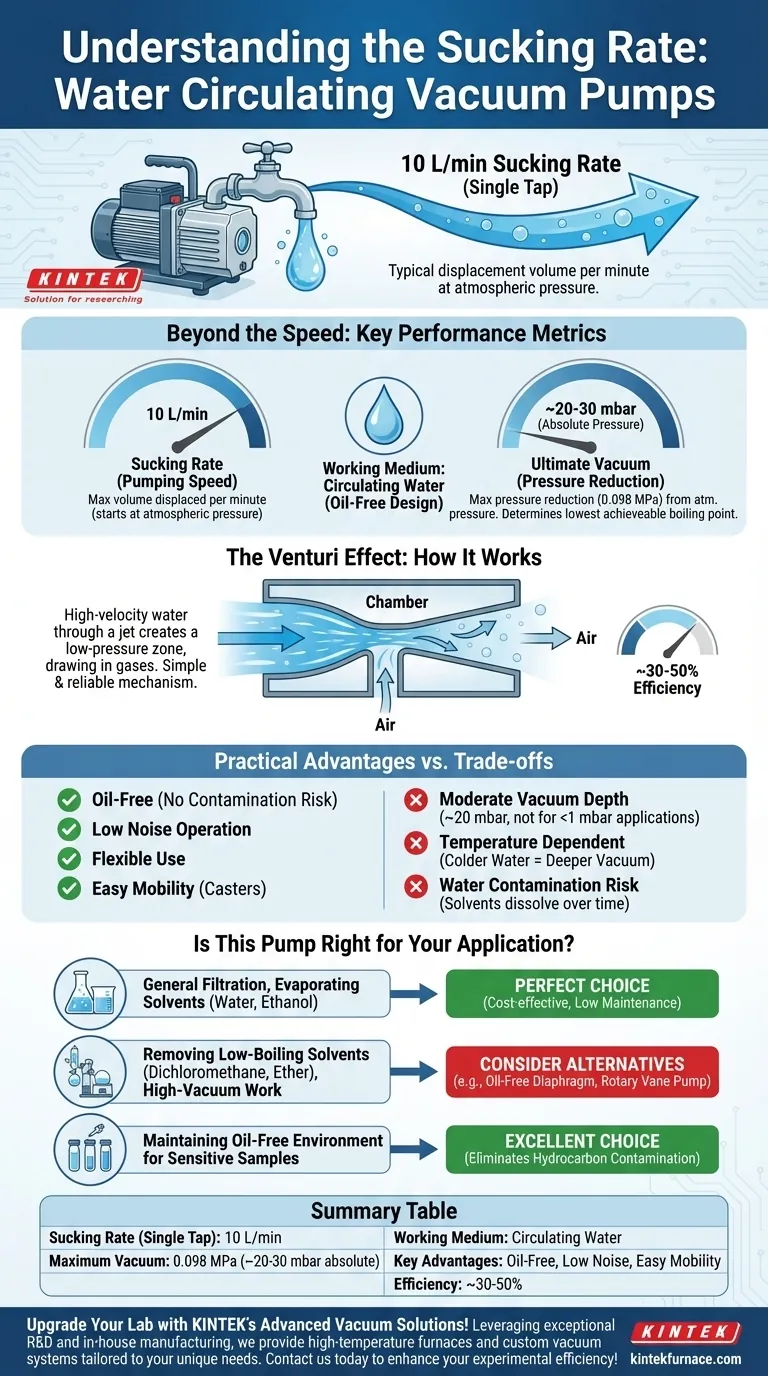

For a typical water circulating vacuum pump, the sucking rate for a single tap is 10 liters per minute (L/min). This specification defines the pump's displacement—the volume of gas it can move from an inlet at atmospheric pressure in a given amount of time.

While the 10 L/min sucking rate defines its speed, the true value of this pump lies in its operational simplicity and oil-free design. Understanding its vacuum depth and how it operates is critical to determining if it meets your specific laboratory needs.

Understanding the Key Performance Metrics

To properly evaluate this pump, you must look beyond the sucking rate and consider its ultimate vacuum capability and the medium it uses.

Sucking Rate (Pumping Speed)

The sucking rate of 10 L/min is the volume of air the pump can displace per minute. This metric is most relevant at the beginning of the pump-down process when the system pressure is near atmospheric levels.

Maximum Vacuum (Ultimate Pressure)

The pump's ability to create a vacuum is specified as a maximum of 0.098 MPa. This value represents the pressure reduction from the standard atmospheric pressure (approx. 0.101 MPa).

This means the pump can lower the pressure inside a sealed system to an absolute pressure of around 20-30 mbar (0.020-0.030 MPa). This ultimate pressure, not the sucking rate, determines the lowest boiling point you can achieve for distillations or the efficiency of processes requiring low pressure.

The Role of Water as the Working Medium

These pumps use circulating water to generate the vacuum. This design choice is fundamental to its primary advantages: it operates without oil and, therefore, introduces no risk of oil-based contamination into your system.

The Principle of Operation and Its Implications

The pump's design directly influences its performance, efficiency, and practical benefits.

How It Works: The Venturi Effect

The vacuum is generated by the Venturi effect. Water is pumped at high velocity through a jet, creating a low-pressure zone that draws in air and other gases from the connected apparatus. The air mixes with the water stream and is then expelled.

Inherent Efficiency

This mechanism, while simple and reliable, has a general efficiency of around 30%, with some high-end models reaching 50%. It is not as energy-efficient as mechanical pumps but offers significant trade-offs in cost and maintenance.

Practical Advantages

The simple design results in several user-friendly characteristics. The pump is known for its low noise, flexible use, and lack of oil changes. Many models are also furnished with casters, making them convenient to move around a lab.

Understanding the Trade-offs

No single solution is perfect. The water circulating pump's strengths in one area create limitations in others.

Moderate Vacuum Depth

The ultimate pressure of ~20 mbar is sufficient for many applications, such as filtration or rotary evaporation of solvents with high boiling points. However, it is not a "high vacuum" pump and is unsuitable for applications requiring pressures below 1 mbar.

Dependence on Water Temperature

The pump's performance is directly tied to the vapor pressure of the circulating water. Colder water will produce a deeper vacuum because it has a lower vapor pressure. As water warms during operation, the ultimate vacuum level will degrade.

Water Contamination

While the pump itself is oil-free, volatile solvents from your experiment can dissolve into the circulating water. Over time, this can affect pump performance and may require the water to be changed periodically to maintain efficiency and comply with waste disposal rules.

Is This Pump Right for Your Application?

Choosing the correct vacuum source requires matching the tool to your specific scientific goal.

- If your primary focus is general lab filtration or evaporating solvents like water or ethanol: The 10 L/min rate and moderate vacuum are perfectly adequate and offer a cost-effective, low-maintenance solution.

- If your primary focus is removing low-boiling-point solvents (e.g., dichloromethane, ether) or performing high-vacuum work: You will need a pump capable of a deeper vacuum, such as an oil-free diaphragm pump or a rotary vane pump.

- If your primary focus is maintaining a completely oil-free environment for sensitive samples: This pump is an excellent choice over traditional oil-sealed pumps, effectively eliminating the risk of hydrocarbon contamination.

By understanding both the speed and limitations of this pump, you can confidently select the right tool for your work.

Summary Table:

| Metric | Specification |

|---|---|

| Sucking Rate (Single Tap) | 10 L/min |

| Maximum Vacuum | 0.098 MPa (absolute pressure ~20-30 mbar) |

| Working Medium | Circulating Water |

| Key Advantages | Oil-Free, Low Noise, Easy Mobility |

| Efficiency | ~30-50% |

Upgrade your lab with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces and custom vacuum systems tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all designed for precision and reliability. Contact us today to discuss how we can enhance your experimental efficiency and achieve superior results!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How many taps does the water circulating vacuum pump have? Choose the Right Model for Your Lab

- What are the technical advantages of using a quartz tube as a reaction chamber? Optimize g-C3N4 Thin Film CVD Processes

- What are the technical advantages of using quartz tubes for fiber optic sensors? Optimize High-Temp Performance

- How does heating equipment with magnetic stirring contribute to Fe3O4 synthesis? Achieve Precise Nanoparticle Control

- Why is a platinum (Pt) crucible selected as the reaction vessel? Ensure Precision in High-Temp Molten Salt Research

- Why is it necessary to use alumina or ceramic crucibles during the high-temperature evaporation of magnesium? Ensure Purity and Process Integrity

- What are the benefits of the improved circulating water vacuum pump? Save Costs and Go Green in Your Lab

- What is the necessity of using an alumina closed-end tube? Protect Your Aluminum Alloy Melting Process