Mass flow controllers (MFCs) serve as the critical regulation mechanism for establishing the precise chemical atmosphere required in laboratory gasification furnaces. By strictly managing the flow rates of gases like carbon dioxide (CO2), carbon monoxide (CO), and nitrogen (N2), these devices allow researchers to dictate the exact gas concentrations entering the reactor with high fidelity.

In gasification studies, the validity of your data hinges on the stability of the reaction environment. MFCs transform variable gas inputs into a stable, reproducible atmosphere, enabling the quantitative analysis of specific reaction kinetics.

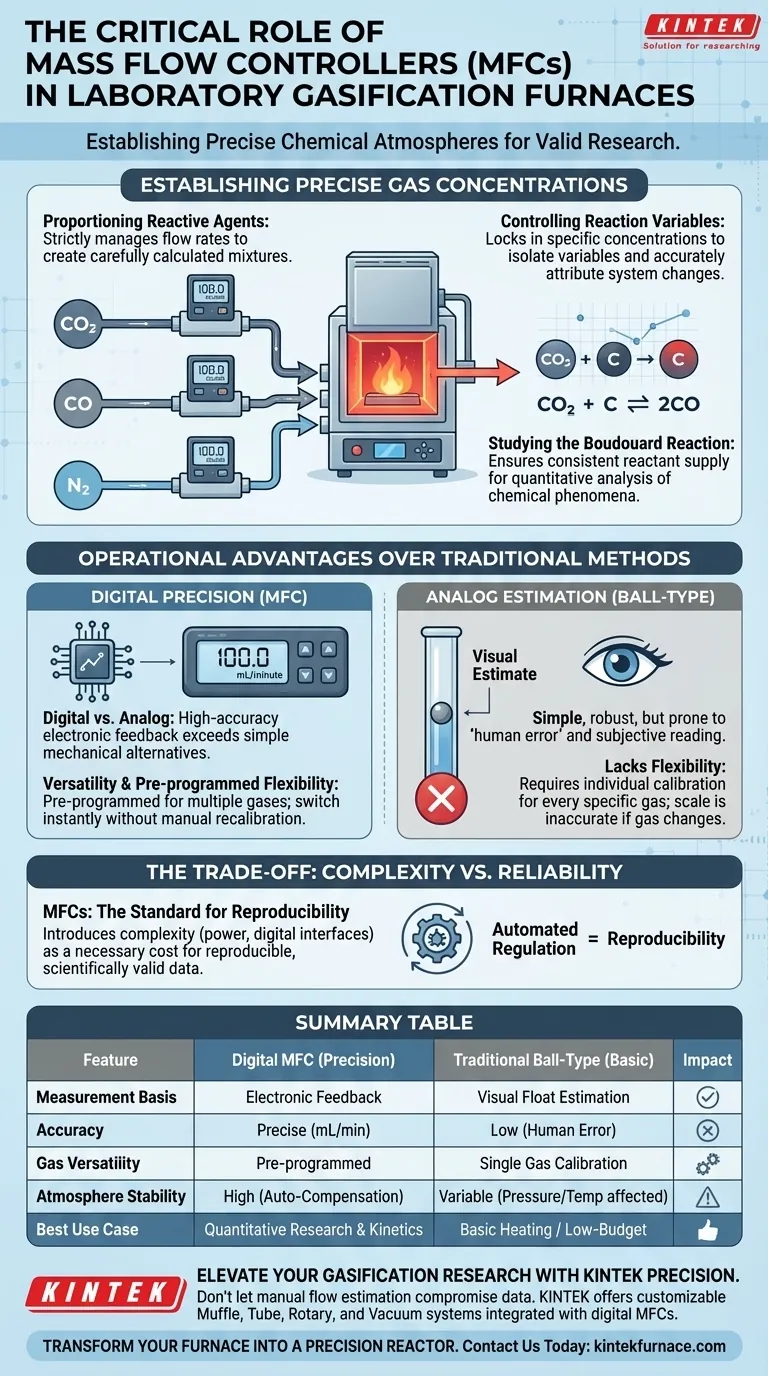

Establishing Precise Gas Concentrations

Proportioning Reactive Agents

In a gasification furnace, the atmosphere is rarely a single gas. It is a carefully calculated mixture.

MFCs are utilized to precisely proportion the input of various gases, specifically carbon dioxide, carbon monoxide, and nitrogen. This ensures the reactor receives the exact chemical composition required for the study.

Controlling Reaction Variables

High-precision regulation allows you to lock in specific gas concentrations.

This capability is essential for isolating variables. By maintaining constant concentrations, you can accurately attribute changes in the system to the specific gasifying agents being tested.

Studying the Boudouard Reaction

Precision is particularly critical when analyzing specific chemical phenomena, such as the Boudouard reaction.

This reaction involves the equilibrium between carbon dioxide and carbon monoxide. An MFC allows researchers to quantitatively study the effects of different agents on the Boudouard reaction rate by ensuring the reactant supply is perfectly consistent.

Operational Advantages Over Traditional Methods

Digital Precision vs. Analog Estimation

Digital MFCs offer a level of control that exceeds simple mechanical alternatives, often measuring flow in milliliters per minute (mL/minute).

Unlike ball-type flow meters, which provide a visual estimate, digital controllers manage the input with high-accuracy electronic feedback.

Versatility in the Laboratory

A significant limitation of older flow measurement tools is their lack of flexibility.

Simple ball-type meters must be calibrated individually for every specific gas used. If you switch from Nitrogen to CO2, the physical scale on the meter may no longer be accurate.

Pre-Programmed Flexibility

Digital MFCs overcome this calibration hurdle.

They can be pre-programmed to manage a wide range of gases accurately. This makes them highly practical for laboratories that frequently switch between different gases for various processes without needing to swap out hardware.

The Trade-off: Complexity vs. Reliability

The Cost of Simplicity

While simple ball-type meters are robust and inexpensive, they introduce "human error" into the equation. Reading the float position is subjective, and the lack of automatic compensation for pressure or temperature changes can skew data.

The Standard for Reproducibility

MFCs introduce more complexity to the setup, requiring power and digital interfaces. However, this is the necessary cost for reproducibility.

Without the automated regulation an MFC provides, replicating an experiment with identical atmospheric conditions is nearly impossible. For quantitative research, reliance on manual flow regulation is a significant liability.

Making the Right Choice for Your Goal

To determine how to best utilize flow control in your system, consider your primary experimental objectives:

- If your primary focus is quantitative reaction kinetics: You must use an MFC to lock in specific concentrations of CO2 and CO to accurately measure the Boudouard reaction rate.

- If your primary focus is laboratory versatility: an MFC allows you to switch between N2, CO, and other gases instantly without manually recalibrating flow meters for each new agent.

Ultimately, the mass flow controller transitions your furnace from a simple heating element into a precision reactor capable of generating scientifically valid data.

Summary Table:

| Feature | Digital Mass Flow Controller (MFC) | Traditional Ball-Type Meter |

|---|---|---|

| Measurement Basis | High-precision electronic feedback | Visual float estimation (Manual) |

| Accuracy | Precise (measured in mL/minute) | Low (prone to human error) |

| Gas Versatility | Pre-programmed for multiple gases | Requires individual calibration per gas |

| Atmosphere Stability | High (automatic compensation) | Variable (affected by pressure/temp) |

| Best Use Case | Quantitative reaction kinetics & research | Basic heating or low-budget setups |

Elevate Your Gasification Research with KINTEK Precision

Don't let manual flow estimation compromise your experimental data. At KINTEK, we understand that valid reaction kinetics depend on a stable atmosphere. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable with integrated digital Mass Flow Controllers to meet your unique high-temperature laboratory needs.

Ready to transform your furnace into a precision reactor? Contact us today to discuss your custom furnace specifications!

Visual Guide

References

- Fernando Leo Bueno - CO₂ Gasification of Black Liquor Char under isothermal and dynamic conditions. DOI: 10.26754/jji-i3a.202512148

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What is the primary purpose of using a high-purity quartz vacuum ampule? Unlock High-Quality WSe2 Crystal Growth

- What types of high-temperature laboratory furnace systems are available? Explore 5 Specialized Solutions

- What are the benefits of using high-purity alumina or platinum crucibles? Enhance Purity in Specialized Glass Melting

- Why is a high-purity graphite crucible typically chosen for the high-temperature vacuum carbothermic reduction of magnesium oxide?

- Why are a press and pelletizing molds necessary when preparing pellets for magnesium smelting? Ensure Smelting Efficiency and Control

- What is the function of high-purity refractory dies in slip-casting? Key Benefits for Precision Ceramic Molding

- What is the function of high-purity alumina crucibles in NRBBO:Eu2+ sintering? Ensure Pure Phosphor Synthesis

- How is a vacuum pump system used to simulate high-altitude gasification conditions? Replicate 3000m Pressure Levels