High-purity alumina and platinum crucibles provide a critical barrier against contamination when processing aggressive high-temperature melts. Their primary function is to maintain superior chemical stability, ensuring that the reactive nature of fluorides or specialized glasses does not degrade the crucible wall and introduce impurities into the final product.

The success of melting specialized glass hinges on the container's ability to remain chemically inert; these materials ensure that the final product's optical transmission and color fidelity are not compromised by the crucible itself.

Preserving Chemical and Optical Integrity

Resisting Slag Erosion

Molten glass and fluoride materials are highly corrosive. High-purity alumina and platinum are selected specifically for their resistance to slag erosion in these extreme environments.

Standard crucibles often degrade under such conditions. This degradation leads to material spalling (flaking), which introduces physical defects into the melt.

Preventing Impurity Infiltration

Beyond physical flakes, a dissolving crucible releases microscopic impurity ions into the liquid glass. Using chemically stable high-purity crucibles prevents this infiltration.

For materials like lithium disilicate glass-ceramics, purity is non-negotiable. Even trace amounts of leached material can ruin the chemical purity required for the material's intended performance.

Ensuring Ideal Light Transmission

The presence of impurity ions is the primary cause of unwanted color deviations in glass.

By using platinum or high-purity alumina, you avoid the performance degradation associated with these impurities. This ensures the final product maintains its ideal light transmission and color neutrality.

Thermal Performance and Process Stability

Withstanding Extreme Temperatures

High-purity alumina crucibles possess exceptional thermal resistance. They are capable of withstanding temperatures exceeding 1450 °C.

At these temperatures, they remain stable and do not react with mineral samples. This inertness is vital for analytical processes like TG-DSC (Thermogravimetric-Differential Scanning Calorimetry), ensuring data reflects only the sample's changes, not the container's.

Locking in Thermal Energy

In high-temperature indirect resistance furnaces, heat transfer is often dominated by radiation.

Crucibles made from or surrounded by high-purity insulating materials help confine the thermal energy within the working zone. This prevents heat diffusion to non-functional parts (like the furnace shell) and ensures the temperature stability of the melting process.

Understanding the Constraints

Specificity of Application

While these materials offer superior resistance, they are chosen for specific, high-stakes environments.

Using these high-grade crucibles is necessary when the reactivity of the melt poses a direct threat to the container. For less active materials, standard crucibles might suffice, but for active fluorides, the chemical inertness of platinum or high-purity alumina is a strict requirement to prevent failure.

Thermal Shock Sensitivity

While alumina has high heat resistance, ceramic materials must be handled carefully regarding temperature changes.

The focus is on chemical stability and steady-state heat resistance. Rapid cooling or heating cycles must be managed to maintain the structural integrity of the crucible over time.

Making the Right Choice for Your Goal

If your primary focus is Optical Quality:

- Select these crucibles to eliminate impurity ions that cause color deviations and reduce light transmission in glass-ceramics.

If your primary focus is Data Accuracy:

- Rely on high-purity alumina for analytical techniques (like TG-DSC) to ensure the heat changes recorded are from the sample, not a reaction with the container.

If your primary focus is Process Stability:

- Use these materials to lock in radiative heat and prevent erosion-related failure during prolonged high-temperature cycles.

Using the correct high-purity crucible turns the container from a liability into a guarantee of product purity.

Summary Table:

| Feature | High-Purity Alumina | Platinum | Benefits |

|---|---|---|---|

| Chemical Stability | Excellent | Superior | Prevents slag erosion and melt contamination |

| Max Temperature | Up to 1450°C+ | High-melting point | Ideal for extreme heat indirect resistance furnaces |

| Optical Impact | Minimal | Zero ions | Ensures color neutrality and light transmission |

| Primary Use | TG-DSC analysis | Active fluorides | Guaranteed material purity and data accuracy |

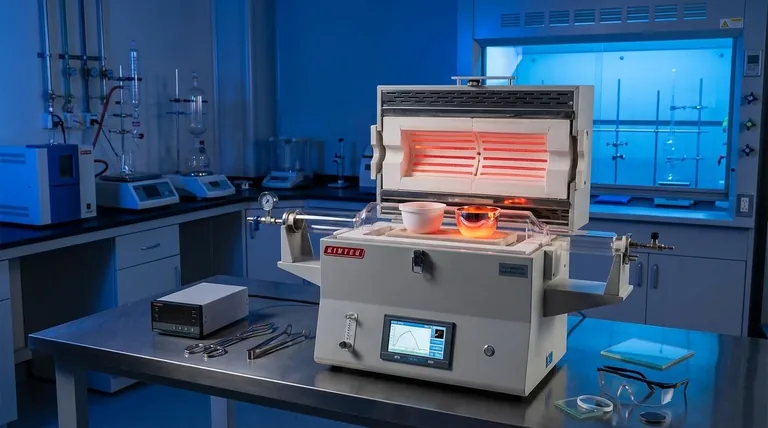

Elevate Your Material Purity with KINTEK

Don't let crucible degradation compromise your specialized glass or fluoride research. Backed by expert R&D and manufacturing, KINTEK offers a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to integrate perfectly with your high-purity alumina or platinum crucible processes.

Ready to ensure peak optical transmission and chemical integrity? Contact us today to find your custom high-temperature furnace solution!

References

- Tao Shang, Xuebing Zhao. A Novel Low-Density-Biomass-Carbon Composite Coated with Carpet-like and Dandelion-Shaped Rare-Earth-Doped Cobalt Ferrite for Enhanced Microwave Absorption. DOI: 10.3390/molecules29112620

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Induction Melting Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is the function of high-alumina crucibles in LLZO calcination? Optimize Battery Material Purity

- How do 15x80mm technical openings and seals boost electric furnace efficiency? Maximize Thermal Performance Today

- Why is graphite foil used to line graphite molds before loading titanium alloy powder? Ensure Purity and Protect Molds

- How does the impeller in a water circulating vacuum pump function to create a vacuum? Discover the Liquid Piston Mechanism

- Why is a gas mixing system essential for syngas annealing in copper powder production? Ensure Precise Embrittlement

- Is there a need to add water when launching the circulating water multifunctional vacuum pump? Ensure Optimal Performance and Avoid Damage

- How does a heating stage contribute to the quality of multi-material 3D printing? Optimize Precision and Stability

- Why is a sintering process using a lab furnace necessary for Li6PS5Cl disks? Enhance Conductivity & Density