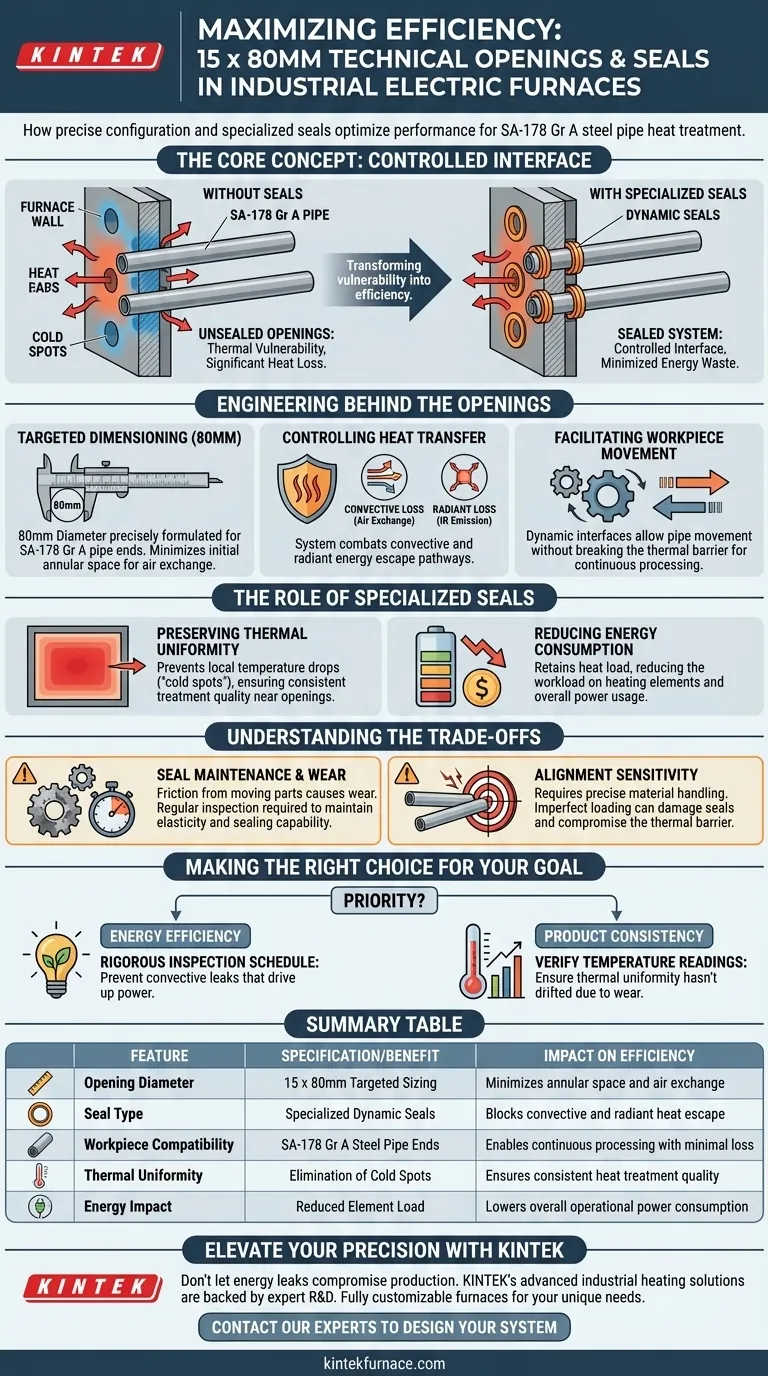

The precise configuration of fifteen 80mm technical openings allows for the targeted heat treatment of SA-178 Gr A steel pipe ends without compromising the furnace's thermal envelope. By integrating specialized seals that accommodate workpiece movement, these openings drastically reduce convective and radiant heat escape, directly translating to stabilized internal temperatures and lower energy requirements.

By effectively isolating the internal environment, these specialized seals transform a potential thermal vulnerability—multiple hull penetrations—into a controlled interface that supports continuous processing while minimizing energy waste.

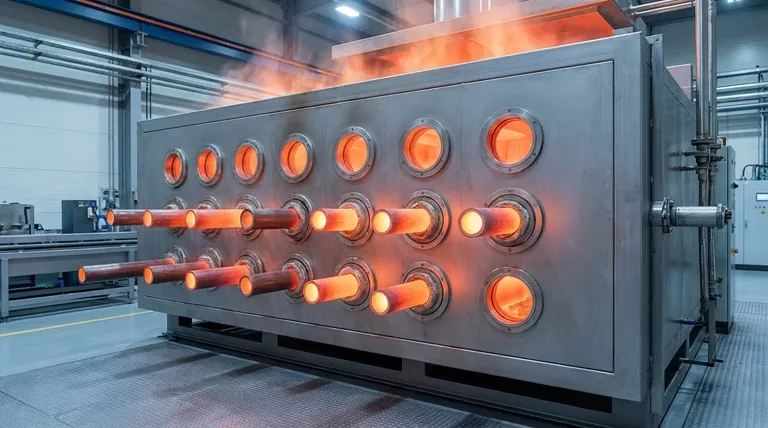

The Engineering Behind the Openings

Targeted Dimensioning

The openings are manufactured with a specific 80mm diameter. This dimension is calculated to accommodate the insertion of SA-178 Gr A steel pipe ends.

By matching the opening size closely to the workpiece, the design naturally limits the annular space available for air exchange. This minimizes the initial potential for heat loss before seals are even applied.

Controlling Heat Transfer Mechanisms

The system is designed to combat two specific types of energy loss: convective and radiant.

Convective loss occurs when hot furnace atmosphere escapes through gaps, while radiant loss involves direct emission of infrared energy. The integration of the openings with the seals blocks both pathways effectively.

Facilitating Workpiece Movement

Industrial heat treatment often requires the movement or rotation of parts during the cycle.

The technical openings are not static plugs; they are dynamic interfaces. The design allows the pipe ends to move as required by the process without breaking the thermal barrier.

The Role of Specialized Seals

Preserving Thermal Uniformity

Consistency is critical in heat treatment. If heat escapes through the openings, it creates "cold spots" near the furnace wall.

The seals prevent these local temperature drops. This ensures that the internal thermal uniformity remains intact, guaranteeing that the pipe ends near the openings receive the exact same treatment as those deeper in the furnace.

Reducing Energy Consumption

When a furnace loses heat, the heating elements must work harder to compensate.

By minimizing leakage through the fifteen openings, the furnace retains its heat load more effectively. This directly reduces the overall energy consumption required to maintain the process temperature.

Understanding the Trade-offs

Seal Maintenance and Wear

While these seals are essential for efficiency, they introduce a maintenance variable. Because they interact with moving workpieces, the seals are subject to friction and mechanical wear.

Degraded seals will compromise both efficiency and thermal uniformity. They require regular inspection to ensure they have not lost their elasticity or sealing capability.

Alignment Sensitivity

The effectiveness of an 80mm opening depends on precise loading.

If the SA-178 Gr A pipes are not aligned perfectly with the openings, they may physically damage the seals during insertion or movement. This requires precise material handling systems to prevent damage to the thermal barrier.

Making the Right Choice for Your Goal

To maximize the value of this furnace configuration, consider your operational priorities:

- If your primary focus is Energy Efficiency: Implement a rigorous inspection schedule for the seals to prevent convective leaks that will silently drive up power usage.

- If your primary focus is Product Consistency: Regularly verify temperature readings near the technical openings to ensure the thermal uniformity has not drifted due to seal wear.

Proper management of these interfaces ensures your furnace operates at peak thermal efficiency.

Summary Table:

| Feature | Specification/Benefit | Impact on Efficiency |

|---|---|---|

| Opening Diameter | 15 x 80mm Targeted Sizing | Minimizes annular space and air exchange |

| Seal Type | Specialized Dynamic Seals | Blocks convective and radiant heat escape |

| Workpiece Compatibility | SA-178 Gr A Steel Pipe Ends | Enables continuous processing with minimal loss |

| Thermal Uniformity | Elimination of Cold Spots | Ensures consistent heat treatment quality |

| Energy Impact | Reduced Element Load | Lowers overall operational power consumption |

Elevate Your Heat Treatment Precision with KINTEK

Don’t let energy leaks compromise your production quality. KINTEK’s advanced industrial heating solutions are backed by expert R&D and manufacturing, offering high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need specialized technical openings or custom thermal barriers, our furnaces are fully customizable to meet your unique laboratory and industrial requirements.

Ready to optimize your thermal efficiency? Contact our experts today to design a high-temperature system tailored to your specific workpiece and energy-saving goals.

Visual Guide

References

- Gustavo Ribeiro Zanini, LUIS CARLOS GERON. PROJETO DE UM FORNO ELÉTRICO INDUSTRIAL PARA TRATAMENTO TÉRMICO TUBOS DE AÇO SA-178 GR A. DOI: 10.52138/citec.v17i01.437

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is graphite foil used to line graphite molds before loading titanium alloy powder? Ensure Purity and Protect Molds

- What is the function of a water-cooled jacket on a sampling probe? Optimize Atomization and Protect Hardware

- What are the risks of using high-purity alumina crucibles for periodate decomposition? Avoid Crucial Data Errors

- What is the function of PTFE sealing rings in plastic pyrolysis? Ensure Safe, Anaerobic Material Decomposition

- What are the advantages of using a Type B thermocouple for 1600°C slag reduction? Precision in Ultra-High Heat

- What is the purpose of an ultrasonic cleaner in NiMo@Cx catalyst prep? Achieve Uniform Slurry & High-Porosity Coatings

- How does excessive gas purging rate affect the alumina furnace tube? Prevent Cracking and Extend Tube Life

- How is the vacuuming operation performed with a water circulating vacuum pump? Master the Liquid Ring Technique