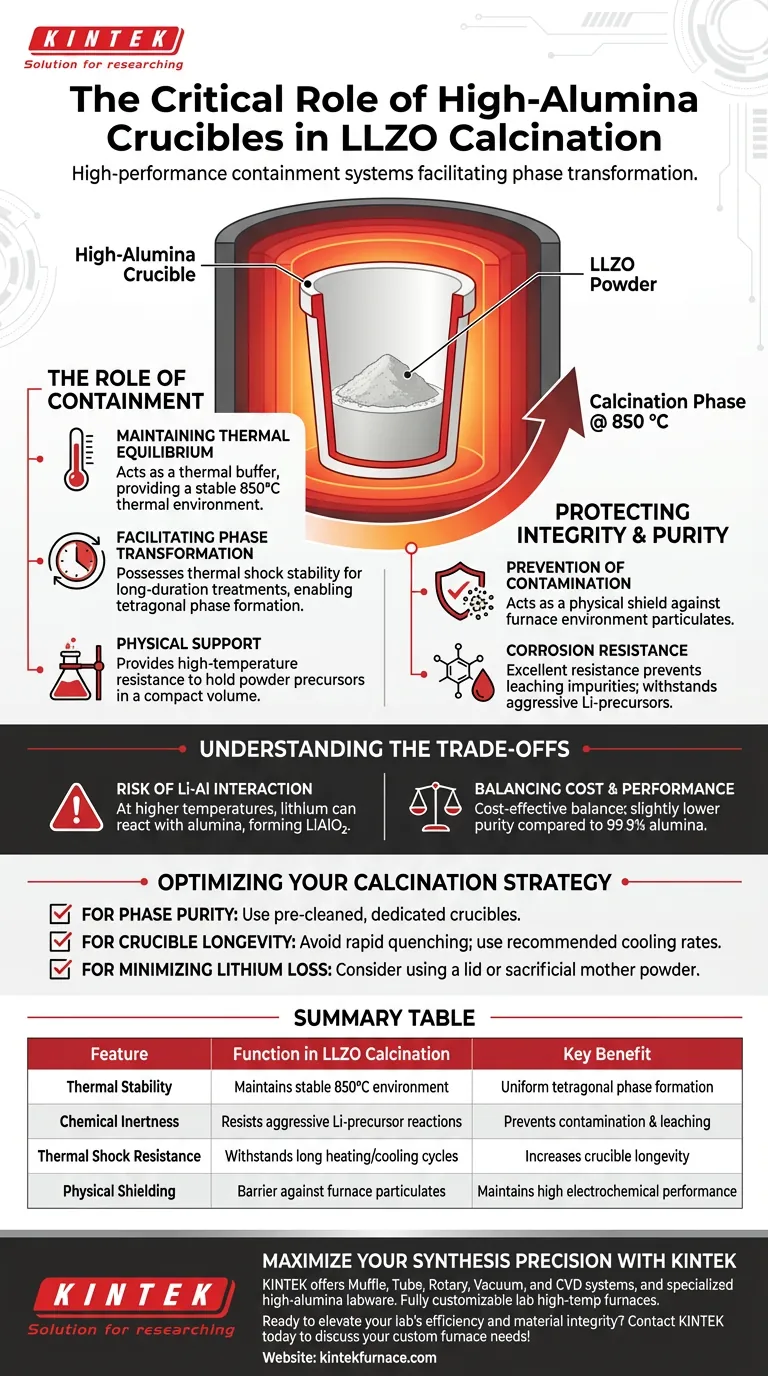

High-alumina crucibles function as high-performance containment systems that facilitate the phase transformation of Li7La3Zr2O12 (LLZO) by providing a stable, 850 °C thermal environment. They serve as a protective barrier, ensuring the powder undergoes long-duration calcination without absorbing environmental impurities or reacting destructively with the vessel itself.

High-alumina crucibles are essential for the calcination of LLZO because they combine extreme thermal shock resistance with chemical inertness, enabling the consistent formation of the tetragonal phase while maintaining high material purity.

The Role of Containment in LLZO Synthesis

Maintaining Thermal Equilibrium at 850 °C

The calcination of LLZO requires a precise and sustained temperature of 850 °C to ensure uniform reaction kinetics. High-alumina crucibles act as a thermal buffer, providing a stable thermal environment that protects the powder from local temperature fluctuations within the furnace.

Facilitating Tetragonal Phase Transformation

The transition into the tetragonal Li7La3Zr2O12 phase is a time-sensitive process that requires long-duration heat treatments. These crucibles possess the thermal shock stability necessary to withstand these extended heating and cooling cycles without structural failure.

Physical Support for Powder Precursors

During the solid-state reaction, the precursor materials must be held in a compact, controlled volume to ensure efficient heat transfer. High-alumina vessels provide the high-temperature resistance required to support the weight and volume of the powder throughout the entire calcination cycle.

Protecting Material Integrity and Purity

Prevention of Environmental Contamination

One of the primary functions of the crucible is to act as a physical shield against the furnace environment. It prevents airborne particulates or furnace heating element off-gassing from contaminating the LLZO samples, which is critical for maintaining electrochemical performance.

Corrosion Resistance and Chemical Stability

LLZO precursors can be chemically aggressive at high temperatures, particularly regarding lithium volatility and reactivity. High-alumina materials offer excellent corrosion resistance, ensuring the crucible does not leach impurities into the powder or degrade during the 850 °C soak.

Understanding the Trade-offs

Risk of Lithium-Alumina Interaction

While high-alumina is generally stable at 850 °C, users must be aware that at higher sintering temperatures, lithium can react with alumina to form secondary phases like LiAlO2. This can lead to lithium loss in the final product and potential crucible degradation over many reuse cycles.

Balancing Cost and Performance

High-alumina is often chosen because it provides a cost-effective balance between durability and chemical inertness compared to more expensive alternatives like platinum or specialized zirconia. However, its slightly lower purity compared to 99.9% alumina must be factored into the final purity analysis of the LLZO powder.

Optimizing Your Calcination Strategy

When selecting and using high-alumina crucibles for LLZO production, consider these specific goals:

- If your primary focus is phase purity: Ensure the crucible is pre-cleaned and dedicated solely to LLZO to prevent cross-contamination from other materials.

- If your primary focus is crucible longevity: Avoid rapid quenching of the crucible, as utilizing its thermal shock stability within recommended cooling rates prevents micro-cracking.

- If your primary focus is minimizing lithium loss: Consider using a lid or "sacrificial" mother powder to further enhance the protective environment provided by the crucible.

By leveraging the thermal stability and chemical protection of high-alumina crucibles, researchers can reliably achieve the phase-pure tetragonal LLZO required for next-generation battery applications.

Summary Table:

| Feature | Function in LLZO Calcination | Key Benefit |

|---|---|---|

| Thermal Stability | Maintains stable 850°C environment | Ensures uniform tetragonal phase formation |

| Chemical Inertness | Resists aggressive Li-precursor reactions | Prevents sample contamination and leaching |

| Thermal Shock Resistance | Withstands long heating/cooling cycles | Increases crucible longevity and reliability |

| Physical Shielding | Barrier against furnace particulates | Maintains high electrochemical performance |

Maximize Your Material Synthesis Precision with KINTEK

Achieving the perfect tetragonal phase in LLZO powders requires more than just high temperatures—it demands uncompromising containment and thermal control. KINTEK provides the high-performance laboratory solutions needed to drive your battery research forward.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-alumina labware. All our lab high-temp furnaces and equipment are fully customizable to meet the unique thermal profiles and purity standards of your specific applications.

Ready to elevate your lab's efficiency and material integrity?

Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- T. Y. Park, Dong‐Min Kim. Low-Temperature Manufacture of Cubic-Phase Li7La3Zr2O12 Electrolyte for All-Solid-State Batteries by Bed Powder. DOI: 10.3390/cryst14030271

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the advantages of using a water circulating vacuum pump? Boost Lab Efficiency with Corrosion Resistance

- What are the roles of laboratory vacuum drying ovens and precision analytical balances in moisture monitoring?

- What are some specialized applications of quartz tubes? Essential for High-Temperature and High-Purity Processes

- What is the function of the nitrogen environment in pyrolysis? Mastering Carbonization with Laboratory Furnaces

- What are the core functions of high-purity graphite molds and graphite paper in SPS? Optimize Sintering Quality

- What makes high-purity alumina crucibles the preferred choice for BZT synthesis? Ensure Purity & Thermal Stability

- Why is molybdenum (Mo) selected as the crucible material for the evaporation of NiO-doped Ga2O3? Expert Insights

- Why is a carrier gas flow control system necessary for thermal sludge treatment? Ensure Precision & Protect Equipment