A water circulating vacuum pump offers significant advantages in resource efficiency, operational robustness, and versatility. Compared to other vacuum technologies, it excels by saving over 35% in electricity, recycling water to reduce consumption, and providing inherent resistance to the corrosive acids, alkalis, and solvents common in laboratory work.

The core reason to choose a water circulating vacuum pump is for its economic and chemical resilience. It is an ideal workhorse for general laboratory vacuum applications, providing a durable, low-maintenance alternative to oil-based pumps, especially when dealing with corrosive vapors.

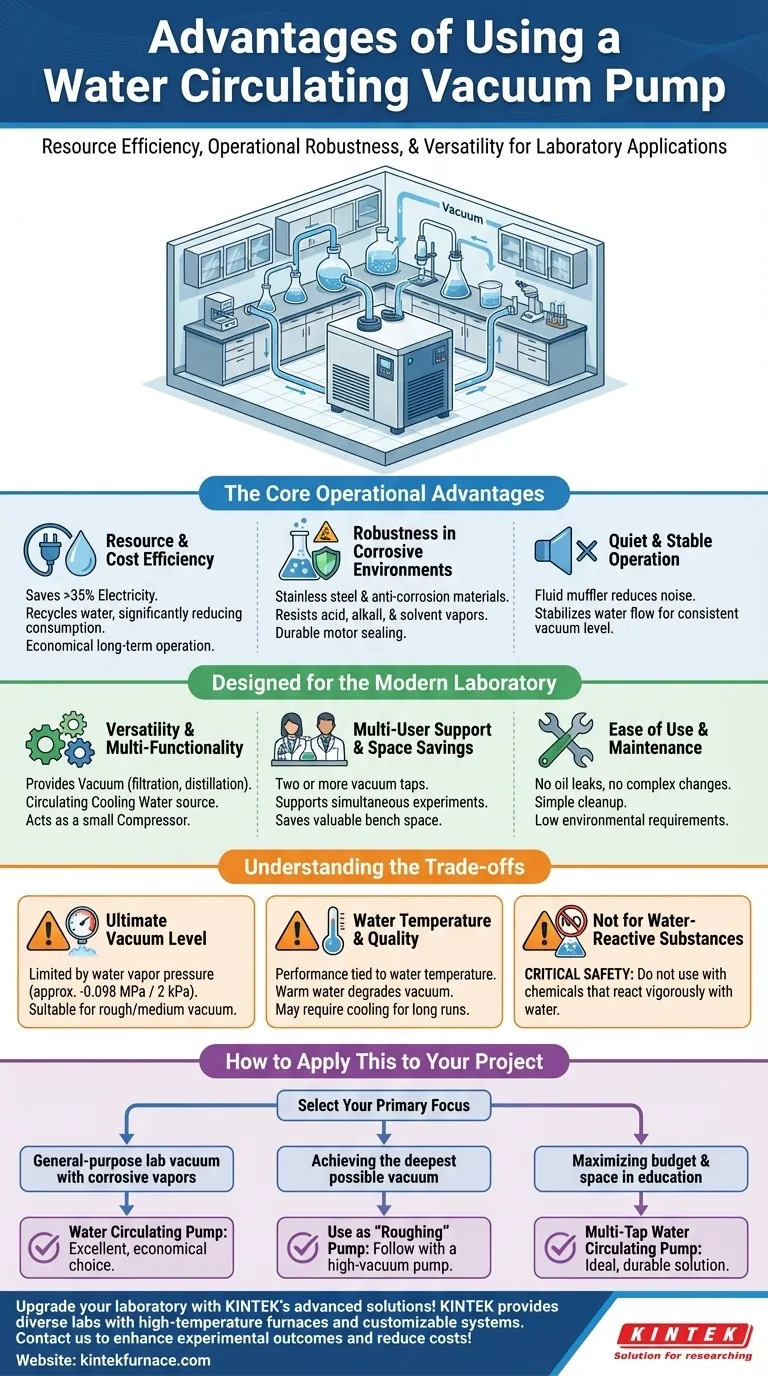

The Core Operational Advantages

A water circulating vacuum pump, also known as a water aspirator or eductor pump, operates on a simple principle: a jet of water creates a pressure drop that pulls gas from a connected vessel. This design leads to several key benefits.

Resource and Cost Efficiency

These pumps are engineered for economy. By continuously recycling the water in their reservoir, they dramatically reduce the water consumption associated with single-pass aspirators.

Furthermore, their efficient design can save more than 35% in electricity compared to other types of vacuum pumps, lowering long-term operational costs.

Robustness in Corrosive Environments

This is a critical advantage over oil-sealed pumps. The pump's wetted parts are typically made of stainless steel or other anti-corrosion materials, making them resistant to damage from acid, alkali, and solvent vapors.

The motor is often specially sealed to prevent corrosive gases from causing internal damage, ensuring a longer and more reliable service life in demanding chemical environments.

Quiet and Stable Operation

Many models include a specialized fluid muffler. This component not only reduces operational noise but also helps stabilize the water flow, which in turn leads to a higher and more consistent vacuum level.

Designed for the Modern Laboratory

Beyond raw performance, these pumps incorporate features specifically for the practical needs of research, educational, and industrial labs.

Versatility and Multi-Functionality

A single unit can often serve three distinct purposes. Its primary role is to provide vacuum for processes like filtration, distillation, and drying.

Second, the recycled water can be used as a source of circulating cooling water for reaction equipment like condensers. In some cases, the pump can even be configured to act as a small compressor.

Multi-User Support and Space Savings

Many units are equipped with two or more vacuum taps. This allows a single pump to be used for multiple experiments or by multiple students simultaneously, either separately or in parallel.

This feature significantly reduces the need for multiple pumps, saving valuable laboratory bench space and budget.

Ease of Use and Maintenance

Compared to oil-sealed pumps, water circulating pumps are mechanically simpler. There are no oil leaks to manage, no complex oil changes, and cleanup is straightforward. Their low environmental requirements make them an easy addition to any lab.

Understanding the Trade-offs

No technology is perfect for every application. To make an informed decision, you must understand the limitations of a water circulating pump.

Ultimate Vacuum Level

The ultimate vacuum of a water circulating pump is limited by the vapor pressure of the water itself. A typical rating is around -0.098 MPa (or 2 kPa), which is considered a rough or medium vacuum.

For applications requiring a high or ultra-high vacuum, an oil-sealed, dry scroll, or turbomolecular pump is necessary.

Water Temperature and Quality

Performance is directly tied to the water in the reservoir. As the water warms up during operation, its vapor pressure increases, which degrades the ultimate vacuum level. For long experiments, the water may need to be changed or externally cooled.

Not for Water-Reactive Substances

This is a critical safety consideration. You cannot use a water-based vacuum system to evacuate a vessel containing chemicals that react vigorously or dangerously with water.

How to Apply This to Your Project

Selecting the right pump requires matching its specifications to your specific process needs.

- If your primary focus is general-purpose lab vacuum with corrosive vapors: A water circulating pump is an excellent, economical choice due to its inherent chemical resistance and low running costs.

- If your primary focus is achieving the deepest possible vacuum for sensitive analysis: This pump is best used for the initial "roughing" stage, followed by a high-vacuum pump like an oil-sealed or turbo pump.

- If your primary focus is maximizing budget and lab space in an educational setting: A multi-tap water circulating pump is the ideal solution, providing vacuum for multiple users from a single, durable unit.

Ultimately, understanding these capabilities and limitations empowers you to select the right tool for your specific scientific or industrial goal.

Summary Table:

| Advantage | Description |

|---|---|

| Resource Efficiency | Saves >35% electricity, recycles water to reduce consumption. |

| Corrosion Resistance | Stainless steel parts resist acids, alkalis, and solvents. |

| Quiet Operation | Fluid muffler reduces noise and stabilizes vacuum levels. |

| Versatility | Provides vacuum, cooling water, and compressor functions. |

| Multi-User Support | Multiple vacuum taps allow simultaneous experiments. |

| Low Maintenance | No oil leaks, simple cleanup, and durable design. |

Upgrade your laboratory with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, plus deep customization to meet unique needs. If you're a researcher or industrial professional seeking reliable, efficient equipment, contact us today to discuss how we can enhance your experimental outcomes and reduce operational costs!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- Why is the integration of a K-type thermocouple and a data logger necessary for Vanadis 60 steel? Unlock Precision.

- What function does a laboratory blast drying oven perform? Optimize Pretreatment for Magnetic Particles

- What are the advantages of using borosilicate glass for the upper atmosphere control chamber? Protect Your Vacuum Seals

- What is the role of specialized sealing ferrules in heating experiments? Ensure Hermetic Isolation and Purity

- Why is a vacuum pump used to evacuate the thermal modification chamber? Ensure Safety and Material Integrity

- Why is an alumina crucible necessary for g-C3N4 synthesis? Ensure High Purity & Stability in Polycondensation

- Why is the use of high-vacuum pump groups critical for photothermal catalytic chamber pre-treatment?

- Why are fume hoods and sealed quartz tubes mandatory for BiF3 and SbF3? Safety in High-Temp Fluoride Reactions