The primary function of a laboratory blast drying oven during this phase is to precisely dehydrate the substrate material to a specific constant moisture content. This process clears the internal pore structures (such as cell lumens in wood-based templates) to allow for the maximum uptake of magnetic precursor solutions, while simultaneously preventing the dilution of subsequent chemical reactions.

The oven acts as a critical preparation tool that balances moisture removal with structural preservation. By clearing internal voids without damaging the organic framework, it ensures the material is chemically receptive to the magnetic precursors used in later synthesis steps.

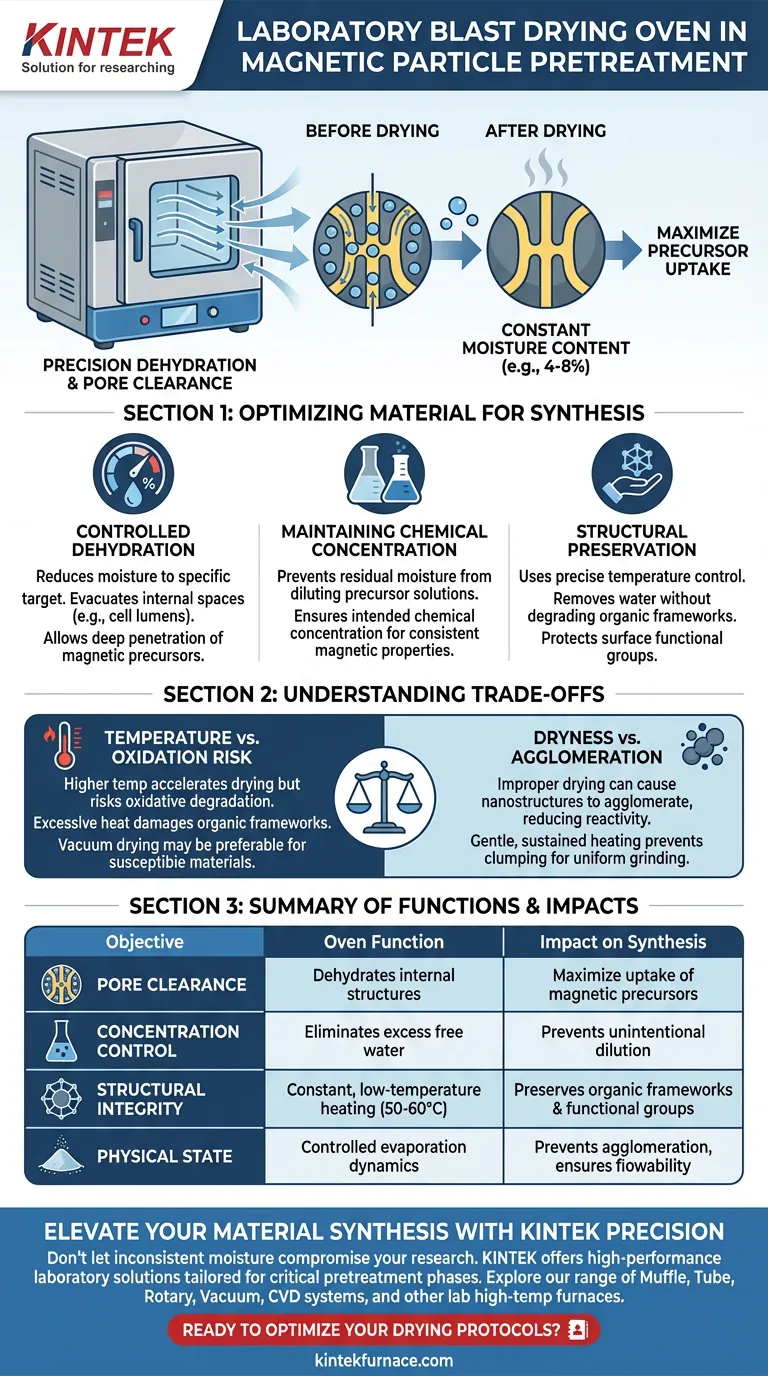

Optimizing the Material for Synthesis

The pretreatment phase is not merely about "drying" the material; it is about conditioning the physical structure of the particle or substrate (such as wood particles used as a magnetic carrier) to ensure the success of the chemical reaction.

Controlled Dehydration and Pore Clearance

The blast drying oven is used to reduce the moisture content of cleaned particles to a specific target, often between 4% and 8%.

By removing excess free water, the oven evacuates the internal spaces, such as cell lumens in organic templates.

This creation of physical space is vital because it allows the magnetic precursor solutions (added in the next step) to deeply penetrate and adsorb into the material structure.

Maintaining Chemical Concentration

If the particles retain too much residual moisture, the water occupying the pores will interact with the precursor solution.

This interaction causes an unintentional dilution of the reaction solution concentration, which can lead to weak or inconsistent magnetic properties in the final product.

The drying oven ensures the substrate is "thirsty" enough to absorb the precursor at the intended chemical concentration.

Structural Preservation

While moisture removal is the goal, the process must be gentle enough to preserve the material's integrity.

The blast drying oven utilizes precise temperature control to remove water without degrading the organic structure of the substrate.

For sensitive materials like magnetic nanocatalysts, maintaining a lower, constant temperature (e.g., 60°C) prevents damage to surface functional groups that are essential for future catalytic activity.

Understanding the Trade-offs

When utilizing a blast drying oven for magnetic particle pretreatment, one must balance drying speed with material stability.

Temperature vs. Oxidation Risk

While higher temperatures accelerate the removal of free water, they pose a risk to the chemical purity of the particles.

Excessive heat can cause oxidative degradation or damage the organic framework of the template, rendering it less effective as a carrier.

For susceptible materials like Fe3O4 precipitates, a vacuum drying environment may be preferable to a standard blast oven to prevent oxidation.

Dryness vs. Agglomeration

Drying is necessary to create a flowable powder, but improper drying dynamics can lead to issues.

Rapid evaporation or excessive temperatures can cause nanostructures to agglomerate (clump together), reducing their surface area and reactivity.

A gentle, sustained heating profile helps maintain the particles in a loose, dispersible state, which is essential for uniform grinding or calcination later.

Making the Right Choice for Your Goal

To ensure the highest quality pretreatment for your magnetic particles, align your drying protocol with your specific synthesis objectives:

- If your primary focus is Precursor Adsorption: Prioritize clearing the pore structure (cell lumens) to a constant low moisture content (e.g., 4-8%) to maximize solution uptake.

- If your primary focus is Structural Integrity: Use lower temperatures (50-60°C) over longer periods to evaporate solvents gently without damaging surface functional groups.

- If your primary focus is Chemical Consistency: Ensure complete removal of free water to prevent the dilution of reaction solutions and ensure accurate mass balance calculations.

The blast drying oven is the gatekeeper of your synthesis, ensuring your substrate is chemically and physically prepared to accept the magnetic properties you intend to engineer.

Summary Table:

| Process Objective | Oven Function | Impact on Synthesis |

|---|---|---|

| Pore Clearance | Dehydrates internal structures (e.g., cell lumens) | Maximize uptake of magnetic precursor solutions |

| Concentration Control | Eliminates excess free water | Prevents unintentional dilution of chemical reactants |

| Structural Integrity | Constant, low-temperature heating (50-60°C) | Preserves organic frameworks and surface functional groups |

| Physical State | Controlled evaporation dynamics | Prevents particle agglomeration and ensures flowability |

Elevate Your Material Synthesis with KINTEK Precision

Don't let inconsistent moisture levels compromise your magnetic particle research. KINTEK provides high-performance laboratory solutions tailored for critical pretreatment phases. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable to meet your unique experimental needs.

Our equipment ensures the precise temperature control required to clear internal pores without damaging sensitive organic templates, giving you total control over precursor adsorption and chemical consistency.

Ready to optimize your drying protocols? Contact us today to find the perfect thermal solution for your lab!

Visual Guide

References

- Róger Moya, Karla J. Merazzo. Magnetic and Physical-Mechanical Properties of Wood Particleboards Composite (MWPC) Fabricated with FE3o4 Nanoparticles and Three Plantation Wood. DOI: 10.22382/wfs-2023-19

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What key functions do graphite molds serve during the hot press sintering? Enhance Ti/Al2O3 Composite Quality

- What are the main applications of laboratory furnaces? Unlock Precision Heat Processing for Your Lab

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency

- What are the advantages of using high-purity quartz boats? Ensure Purity in Carbon Nanotube Synthesis

- How do quartz crucibles and quartz cover plates protect the substrate? Optimize TiO2 Nanowire Growth

- What is the technical purpose of double-sealing raw materials in vacuum quartz tubes? Expert Synthesis Guide

- What are the structural functions of the dual-chamber quartz glass container? Optimize Magnesium Alloy Vapor Analysis

- How does the gas mixing system in plasma nitriding equipment regulate the quality of the diffusion layer?