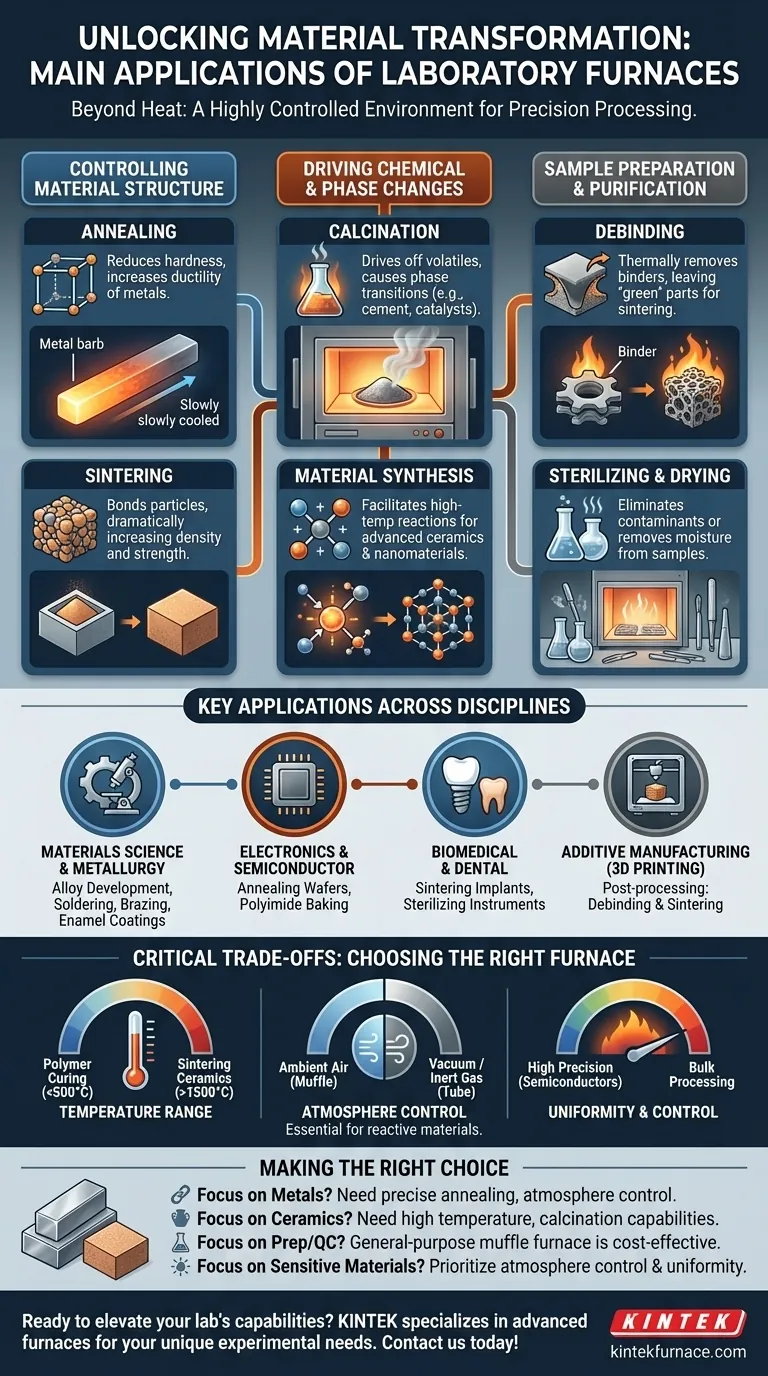

At their core, laboratory furnaces are precision instruments designed for the high-temperature thermal processing of materials. Their main applications fall into three broad categories: modifying the physical properties of a material (like annealing metals), driving chemical reactions or phase changes (like creating ceramics), and preparing samples for further analysis (like drying or sterilizing).

A laboratory furnace is not just an oven; it is a highly controlled environment used to intentionally alter a material's structure, composition, or state at a molecular level. Understanding the specific transformation you need to achieve is the key to selecting the right application.

Beyond Heat: The Core Functions of a Laboratory Furnace

While they all generate heat, different furnace applications leverage that energy for distinct scientific purposes. The goal is always a controlled transformation.

Controlling Material Structure

Many applications focus on altering the internal crystal structure of a material to change its bulk properties.

Annealing is a process of heating and slow cooling used to reduce hardness and increase the ductility of metals, making them less brittle and easier to work with.

Sintering involves heating a compacted powder (like a ceramic or metal) to just below its melting point. This causes the particles to bond and fuse, dramatically increasing the material's density and strength.

Driving Chemical and Phase Changes

Heat can be a powerful catalyst for creating new materials or purifying existing ones.

Calcination is the process of heating a solid to high temperatures in the absence of air to drive off volatile substances, cause phase transitions, or remove water. This is fundamental in cement production and preparing catalysts.

Material synthesis uses the furnace to facilitate chemical reactions at high temperatures, enabling the creation of advanced ceramics, composites, and novel nanomaterials that would not form at room temperature.

Sample Preparation and Purification

In many analytical and manufacturing workflows, the furnace serves as a critical preparatory step.

Debinding is the thermal removal of binder materials used in processes like powder metallurgy or metal injection molding, leaving behind a "green" part ready for sintering.

Sterilizing and drying use high temperatures to eliminate microbial contaminants from lab equipment or remove moisture and solvents from samples before weighing or further processing.

Key Applications Across Scientific Disciplines

The fundamental processes of a furnace are applied across a wide range of specialized fields.

In Materials Science & Metallurgy

This is the traditional home of the furnace. It's used for developing new alloys, creating ceramic components, soldering and brazing metal pieces together, and applying enamel coatings.

In Electronics & Semiconductor Research

Furnaces are essential for manufacturing microelectronics. Processes like annealing silicon wafers repair crystal lattice damage, while polyimide baking is used to cure insulating layers on circuit boards.

In Biomedical & Dental Fields

The biocompatibility and strength of many medical materials depend on furnace processing. This includes sintering ceramic dental crowns and biocompatible implants to achieve their final strength and sterilizing surgical instruments.

In Additive Manufacturing (3D Printing)

Furnaces are critical for post-processing 3D-printed metal and ceramic parts. After printing, parts undergo debinding and sintering cycles to transform them from a fragile state into fully dense, high-strength functional components.

Understanding the Trade-offs: Not All Furnaces Are Equal

Choosing the right furnace depends entirely on the specific application, as different designs offer critical trade-offs.

Temperature Range vs. Application

A furnace for polymer curing (typically under 500°C) is fundamentally different from one used for sintering zirconia ceramics (often requiring temperatures above 1500°C). The required temperature is the first and most important specification.

Atmosphere Control: The Critical Difference

Many materials will oxidize or react undesirably with air at high temperatures. A simple muffle furnace operates in ambient air, which is fine for applications like ashing or basic heat-treating.

However, sensitive processes require a tube furnace or a specialized chamber that can operate with a vacuum or be filled with an inert gas like argon. This atmosphere control is essential for annealing reactive metals or synthesizing air-sensitive compounds.

Uniformity and Control

For applications like semiconductor processing, temperature uniformity across the entire sample is paramount to achieving consistent results. Less sensitive bulk processes may not require such stringent control, allowing for simpler and larger furnace designs.

Making the Right Choice for Your Goal

To select the correct process, first define your desired outcome. Your goal determines the tool.

- If your primary focus is strengthening or altering metals: You need a furnace capable of precise annealing, brazing, or heat-treatment cycles, possibly with atmosphere control for reactive alloys.

- If your primary focus is creating new ceramic or composite materials: You require a high-temperature furnace for sintering and calcination, paying close attention to maximum temperature and atmosphere capabilities.

- If your primary focus is sample preparation or quality control: A general-purpose muffle furnace for ashing, drying, or basic sterilization is often the most cost-effective and practical choice.

- If your primary focus is processing sensitive materials: You must prioritize a furnace with excellent atmosphere control and temperature uniformity, such as a tube furnace.

Ultimately, a laboratory furnace is a tool that gives you precise control over the transformative power of heat.

Summary Table:

| Application | Key Processes | Typical Industries |

|---|---|---|

| Material Structure Control | Annealing, Sintering | Materials Science, Metallurgy |

| Chemical & Phase Changes | Calcination, Material Synthesis | Electronics, Ceramics |

| Sample Preparation | Debinding, Sterilizing, Drying | Biomedical, Additive Manufacturing |

Ready to elevate your lab's capabilities with tailored high-temperature solutions? KINTEK specializes in advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, backed by deep customization to meet your unique experimental needs. Contact us today to discuss how we can enhance your processes—get in touch now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production