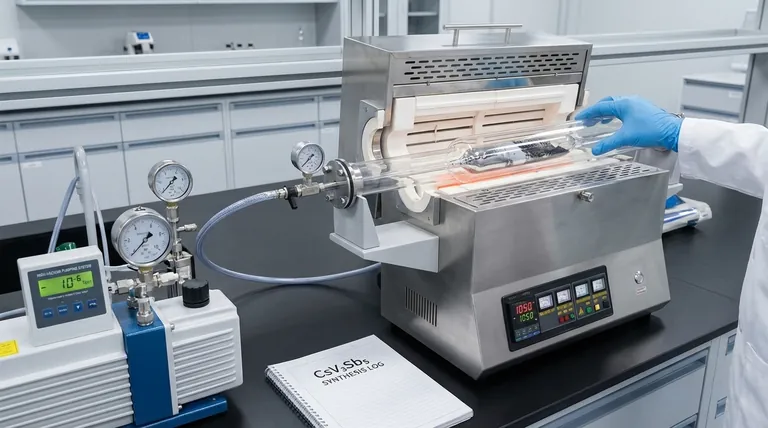

The primary technical purpose of double-sealing raw materials in vacuum quartz tubes during the synthesis of CsV3Sb5 is to totally isolate highly reactive alkali metals from the environment. This technique prevents immediate oxidation and moisture contamination, ensuring the reactants remain pure before and during the reaction.

By maintaining a high-vacuum environment (< 10^-6 Torr), double-sealing preserves the precise chemical stoichiometry required for synthesis and ensures experimental safety during extreme heating cycles.

The Critical Need for Environmental Isolation

Combating Alkali Metal Reactivity

The synthesis of CsV3Sb5 relies on raw alkali metal materials, such as Cesium (Cs). These materials are chemically unstable and highly reactive when exposed to standard atmospheric conditions.

Eliminating Oxygen and Moisture

If left unsealed, these raw materials will rapidly oxidize or react with moisture in the air. Double-sealing effectively creates a barrier, locking out oxygen and humidity to maintain the material's integrity.

Maintaining Process Integrity

Preserving Chemical Stoichiometry

Successful synthesis depends on an exact ratio of ingredients, known as chemical stoichiometry. Any reaction with the air alters the mass and composition of the starting materials, which would ruin the final compound. Double-sealing ensures that the "recipe" remains exact inside the tube.

Ensuring Safety at High Temperatures

The synthesis process involves heating the materials to extreme temperatures, reaching as high as 1050 °C. The double-sealing technique provides a robust containment system, which is critical for maintaining experimental safety under these intense thermal conditions.

Critical Constraints and Risks

The High-Vacuum Requirement

This is not a standard sealing process; it requires a rigorous vacuum level of lower than 10^-6 Torr. Failing to achieve this specific pressure threshold compromises the isolation, rendering the double-seal ineffective against microscopic contaminants.

Vulnerability to Oxidation

The "trade-off" here is the zero-tolerance for error. Because the alkali metals are so prone to oxidation, even a minor breach or inadequate seal will lead to immediate degradation of the reactants and potential failure of the synthesis.

Ensuring Synthesis Success

To achieve high-quality CsV3Sb5 crystals, prioritize your sealing parameters based on your specific operational goals:

- If your primary focus is Purity: Ensure your vacuum system consistently pulls pressures lower than 10^-6 Torr to prevent even trace oxidation errors in stoichiometry.

- If your primary focus is Safety: Verify the structural integrity of the quartz double-seal to withstand the internal pressures generated at 1050 °C.

Rigorous environmental isolation is the single most important factor in managing the reactivity of alkali metals during this synthesis.

Summary Table:

| Parameter | Requirement | Purpose |

|---|---|---|

| Vacuum Level | < 10^-6 Torr | Prevents trace oxidation and contamination |

| Max Temperature | Up to 1050 °C | Ensures containment during thermal cycles |

| Key Materials | Alkali Metals (Cs) | Isolates highly reactive elements from air |

| Process Goal | Stoichiometry | Maintains precise chemical ratios for purity |

Elevate Your Material Synthesis with KINTEK

Precise control over high-vacuum and thermal environments is essential for successful CsV3Sb5 synthesis. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for sensitive laboratory applications.

Our lab high-temp furnaces are fully customizable to meet your unique sealing and heating requirements, ensuring the safety and integrity of your reactive material processes.

Ready to optimize your experimental results? Contact us today to discuss your custom furnace needs with our technical specialists.

References

- Yongqing Cai, Kai Chen. Emergence of quantum confinement in topological kagome superconductor CsV3Sb5. DOI: 10.1038/s43246-024-00461-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the advantages of using a single-mode microwave generator? Precision Heating for Metal Recovery

- What is the function of high-purity graphite molds during SPS of Cu2Se? Essential Tips for Superior Sintering

- What are the technical advantages of using ceramic crucibles for moxa floss pyrolysis? Ensure Precise Thermal Analysis

- Why is an alumina crucible required for bauxite residue thermal analysis? Ensure Stability and Data Purity Up to 1400°C

- What advantages do boron nitride (BN) crucibles offer for molten FUNaK salt? Ensure Purity & High-Temp Stability

- What are the functions of a high-purity graphite mold during the SPS process? Beyond Containing the Powder

- What types of trays are compatible with MoSi2 heating elements? Ensure Optimal Performance and Longevity

- Why is a heating magnetic stirrer used for the acid activation of zeolites? Precision in Thermal & Kinetic Control