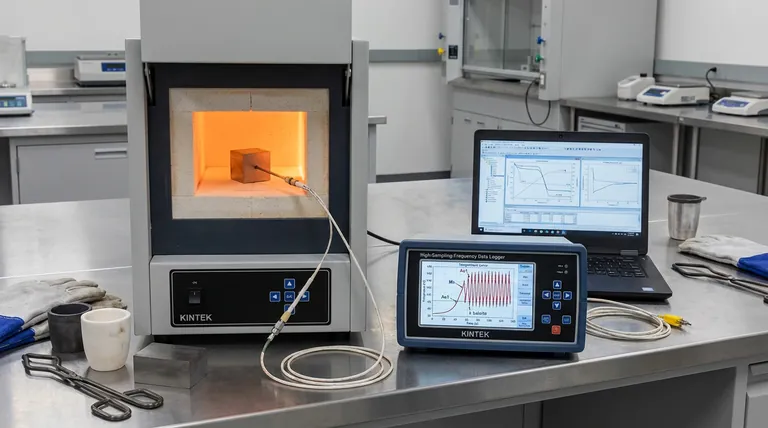

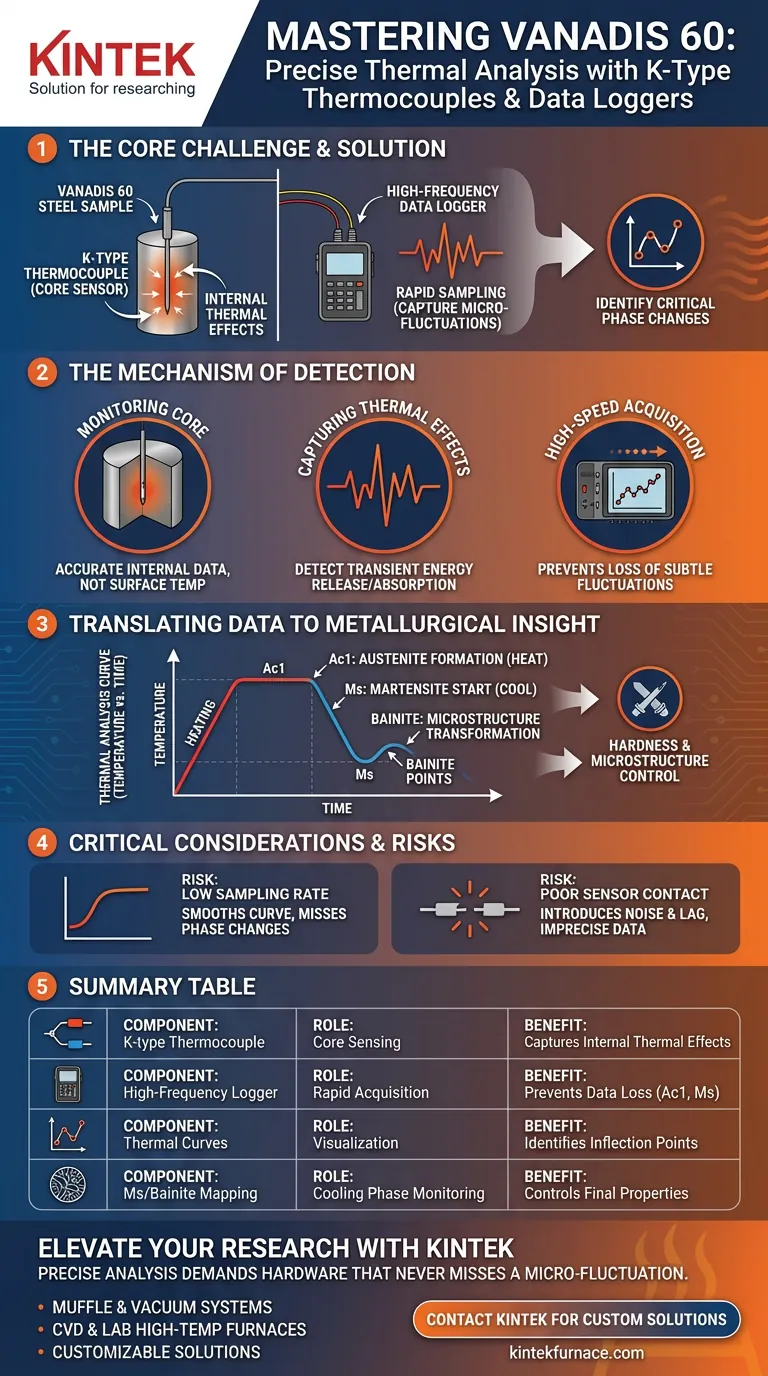

To precise identifying critical transformation temperatures in Vanadis 60 steel, you must integrate a K-type thermocouple with a high-sampling-frequency data logger to capture rapid thermal events that standard monitoring misses. This specific combination enables the detection of real-time temperature fluctuations within the sample's core, providing the granular data required to identify phase changes such as the Ac1, Martensite start (Ms), and bainite transformation points.

Phase transformations in Vanadis 60 steel generate distinct but often subtle thermal effects. The synergy between a core-embedded sensor and high-speed data acquisition bridges the gap between simple heating and identifying the precise microstructural changes required for thermal analysis.

The Mechanism of Thermal Detection

Monitoring the Sample Core

To accurately assess Vanadis 60 steel, temperature data must be gathered from the core of the sample rather than the surface. The K-type thermocouple provides the physical probe necessary to access this internal environment where the material properties are most critical.

Capturing Real-Time Fluctuations

Phase transformations involve the release or absorption of energy, creating momentary thermal effects during heating and cooling. These fluctuations are often transient and can easily be lost if data is not recorded continuously.

High-Frequency Data Logging

A standard thermometer is insufficient for this task; a high-sampling-frequency data logger is required. This device records the thermocouple's output at rapid intervals, ensuring that every micro-fluctuation in temperature is captured for analysis.

Translating Data into Metallurgical Insight

Constructing Thermal Analysis Curves

The raw data collected by the logger is not the end result; it is the raw material used to construct thermal analysis curves. These curves visualize the temperature history of the steel and reveal deviations caused by phase changes.

Identifying Ac1 Temperatures

One of the primary goals of this setup is to locate the Ac1 temperature. This critical parameter marks the beginning of austenite formation during heating, which is clearly visible as an inflection point on a high-resolution thermal curve.

Pinpointing Martensite and Bainite Points

During the cooling phase, the steel undergoes hardening transformations. The integrated system allows you to precisely identify the Martensite start (Ms) temperature and bainite transformation points, which dictate the final hardness and microstructure of the steel.

Critical Considerations and Trade-offs

The Risk of Low Sampling Rates

The most common pitfall in this process is utilizing a data logger with an insufficient sampling frequency. If the logger records data too slowly, it will "smooth out" the thermal curve, effectively erasing the subtle thermal effects that indicate a phase change.

Dependency on Sensor Contact

The integrity of the data relies entirely on the K-type thermocouple maintaining consistent contact with the steel core. Any air gaps or loose connections will introduce noise or lag, rendering the identification of precise points like the Ms temperature impossible.

Making the Right Choice for Your Goal

To ensure you are gathering actionable metallurgical data, tailor your approach based on your specific analytical needs:

- If your primary focus is defining heat treatment cycles: Ensure your data logger frequency is high enough to detect the exact onset of the Ac1 temperature to avoid under-heating the material.

- If your primary focus is controlling hardness and microstructure: Prioritize the precise mapping of the Martensite start (Ms) and bainite points during the cooling phase to predict final material properties.

Successful characterization of Vanadis 60 relies not just on heating the steel, but on the rigorous, high-speed documentation of how it responds to that heat.

Summary Table:

| Component | Role in Vanadis 60 Analysis | Benefit for Metallurgical Results |

|---|---|---|

| K-type Thermocouple | Core temperature sensing | Captures internal thermal effects during phase shifts |

| High-Frequency Logger | Rapid data acquisition | Prevents loss of subtle data points like Ac1 and Ms |

| Thermal Curves | Visualization of temperature data | Identifies precise inflection points for austenite formation |

| Ms/Bainite Mapping | Cooling phase monitoring | Ensures control over final hardness and microstructure |

Elevate Your Metallurgical Research with KINTEK

Precise thermal analysis of advanced materials like Vanadis 60 requires hardware that never misses a micro-fluctuation. KINTEK provides industry-leading solutions backed by expert R&D and manufacturing. From Muffle and Vacuum systems to specialized CVD and Lab High-Temp Furnaces, our equipment is fully customizable to meet your unique metallurgical needs.

Don't let low sampling rates or inconsistent sensors compromise your material properties. Ensure your lab has the precision it deserves—Contact KINTEK today to discuss your custom furnace and data integration solutions!

Visual Guide

References

- Florentino Álvarez-Antolín, Alejandro González-Pociño. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Vanadis 60 Steel: A Statistical Design Approach. DOI: 10.3390/solids6030046

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the technical considerations for selecting a stainless steel cylindrical vessel? Magnesium Test Chamber Guide

- Why is a tantalum (Ta) crucible essential for Li3-3xScxSb sintering? Ensure Pure Phase Stability at 1143 K

- Why is a high-purity Alumina Crucible required during the annealing of MoS2? Ensure High-Temperature Material Purity

- Why are quartz tubes indispensable in advanced technologies? Unlock Purity and Performance

- What is the specific purpose of a Boron Nitride (BN) furnace lid? Protecting Molten Steel Purity

- What functions do high-strength graphite molds serve in FAST? Optimize Titanium Alloy Consolidation Today

- What function do high-strength graphite molds serve? Essential Roles in Ti-6Al-4V Vacuum Hot Pressing

- How does a laboratory vacuum pump system contribute to the preparation process of TixNbMoTaW refractory alloys?