High-strength borosilicate glass serves as the critical interface between extreme internal processing conditions and the external environment in high-temperature sintering devices. It provides a robust, airtight enclosure that isolates sensitive connection points from the intense heat of the furnace body.

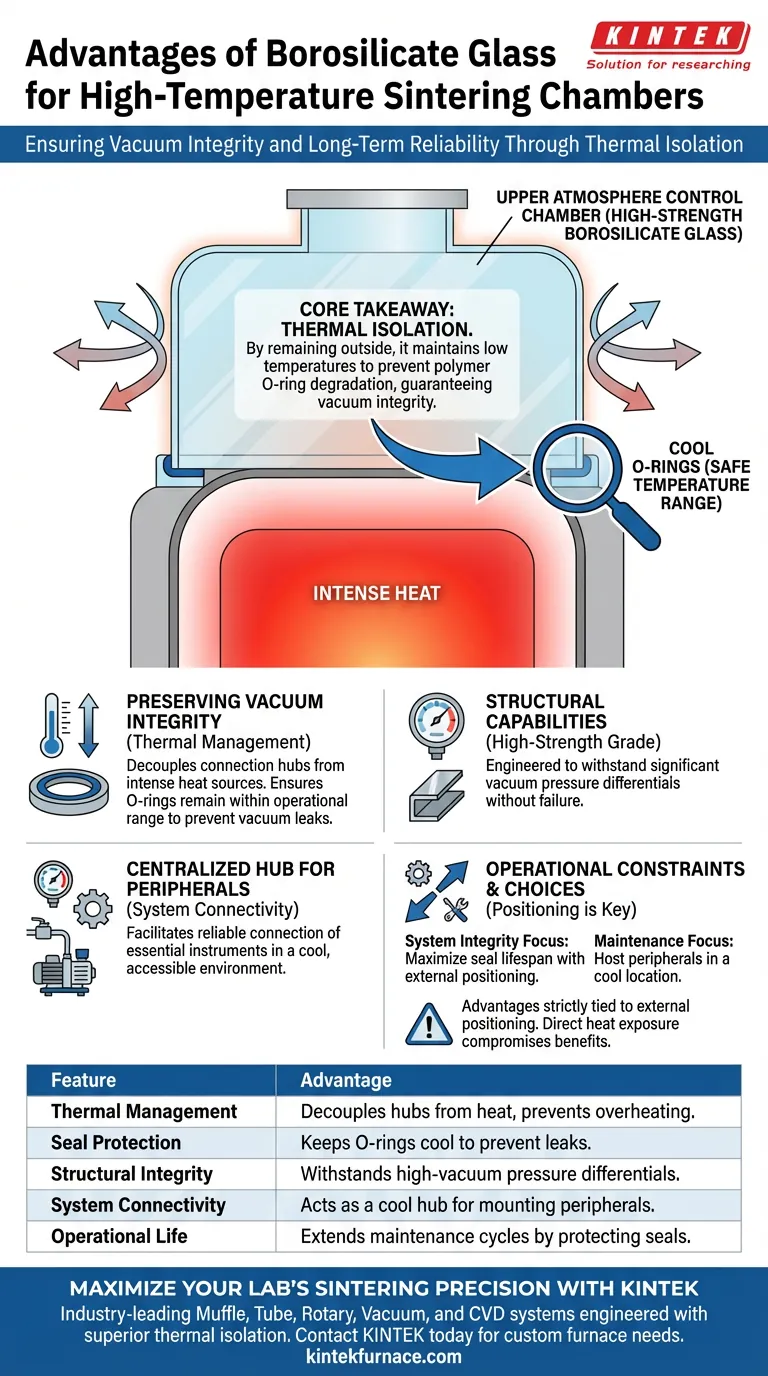

Core Takeaway The primary value of using borosilicate glass in the upper chamber is thermal isolation. By remaining outside the main furnace body, the glass maintains a low enough temperature to prevent polymer O-rings from degrading, thereby guaranteeing the long-term airtightness and vacuum integrity of the system.

Preserving Vacuum Integrity Through Thermal Management

Thermal Isolation of Sealing Components

The most significant challenge in high-temperature sintering is maintaining a vacuum seal while the furnace generates intense heat. Borosilicate glass effectively decouples the connection hub from the heat source.

Because the glass chamber is positioned outside the furnace body, it does not experience the full thermal load of the sintering process.

Ensuring O-Ring Stability

Vacuum systems rely heavily on polymer O-ring seals to prevent leaks. These polymers are sensitive to high temperatures and can degrade or melt if exposed to the furnace's internal heat.

By maintaining a lower surface temperature, the borosilicate glass ensures these O-rings remain within their operational temperature range. This stability is the key factor in maintaining the overall airtightness of the vacuum system.

Structural Capabilities and Connectivity

Withstanding Vacuum Pressure

Despite being a glass material, the specific grade used in these applications is high-strength borosilicate.

It is engineered to possess the structural integrity necessary to withstand the significant pressure differentials created by high-vacuum environments without failure.

Centralized Hub for Peripherals

The upper chamber acts as the central nervous system for the device's atmosphere control.

The glass structure facilitates the reliable connection of essential peripherals, including pressure gauges, vacuum pumps, and gas ports. It allows these instruments to interface with the vacuum environment without being subjected to damaging thermal stress.

Understanding the Operational Constraints

Reliance on External Positioning

It is critical to understand that the advantages of this component are strictly tied to its location.

The glass functions effectively because it remains outside the furnace body. If the design of the device were to expose this chamber to the direct radiant heat of the sintering zone, the thermal benefits regarding seal preservation would be compromised.

Making the Right Choice for Your Design

When evaluating the design of a sintering furnace, consider how the upper chamber material aligns with your operational requirements.

- If your primary focus is System Integrity: Ensure the upper chamber is positioned well outside the heating zone to maximize the lifespan of your O-ring seals.

- If your primary focus is Maintenance and Monitoring: Value the borosilicate design for its ability to host vacuum pumps and pressure gauges in a cool, accessible location.

Ideally, the upper chamber should function as a thermal break, keeping the vacuum in and the heat away from your seals.

Summary Table:

| Feature | Advantage of Borosilicate Glass |

|---|---|

| Thermal Management | Decouples connection hubs from intense furnace heat to prevent overheating. |

| Seal Protection | Keeps O-rings at safe temperatures to prevent degradation and vacuum leaks. |

| Structural Integrity | High-strength grade withstands significant vacuum pressure differentials. |

| System Connectivity | Acts as a cool hub for mounting pressure gauges, pumps, and gas ports. |

| Operational Life | Extends maintenance cycles by protecting sensitive sealing components. |

Maximize Your Lab's Sintering Precision with KINTEK

Maintaining a perfect vacuum environment is critical for high-purity sintering. KINTEK provides industry-leading high-temperature solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—engineered with superior thermal isolation to protect your seals and ensure long-term reliability. Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique atmospheric and temperature requirements.

Ready to upgrade your research capabilities? Contact KINTEK today to discuss your custom furnace needs and experience the value of precision engineering.

Visual Guide

References

- María E. Hernández-Rojas, Sandro Báez–Pimiento. A Device with a Controllable Internal Atmosphere, Independent from the Heating Furnace, for Sintering Metal Particles. DOI: 10.1590/1980-5373-mr-2023-0401

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

- Ultra High Vacuum CF Observation Window Flange with High Borosilicate Glass Sight Glass

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What processes can a circulating water vacuum pump provide negative pressure conditions for? Essential Lab Techniques Explained

- What are the material requirements for the core reaction chambers? Ensure Pure Pyrolysis with Quartz and Corundum

- What is the function of a high alumina crucible in chloride salt purification? Protect Purity and Thermal Stability

- Why is a vacuum pump used to evacuate the thermal modification chamber? Ensure Safety and Material Integrity

- What is the primary purpose of a benchtop blast drying oven? Optimize Barium Titanate Ceramic Preparation

- Why is a precise gas flow control and supply system necessary during the thermochemical conversion of rice husk biochar?

- What are the advantages of using a platinum crucible? Essential for High-Purity Alumino-Borosilicate Glass Synthesis

- What is the purpose of a water-cooled condenser in a thermal vacuum mercury removal apparatus? Key for Safe Recovery