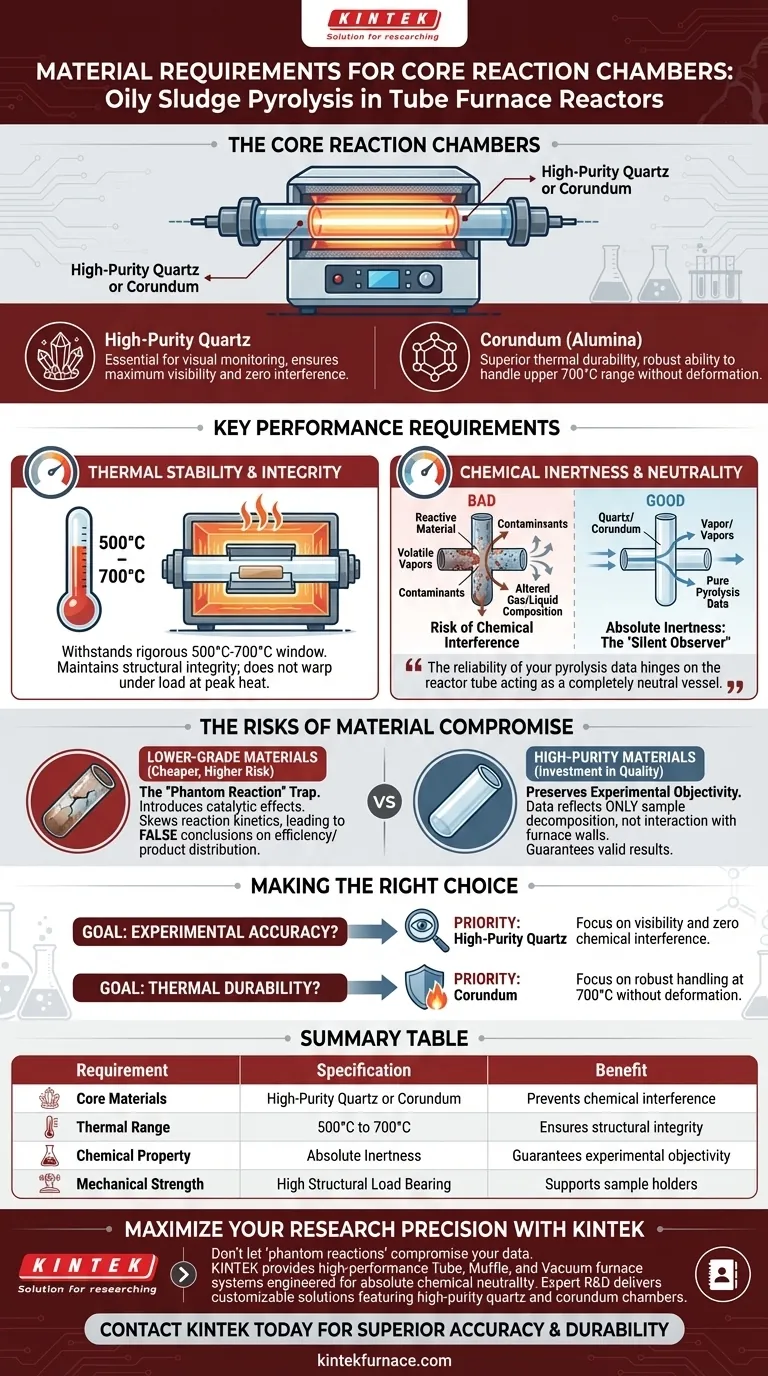

The core reaction chambers in Tube Furnace Reactors for oily sludge pyrolysis must be constructed from high-purity quartz or corundum. These materials are essential because they possess the specific thermal stability required to operate between 500°C and 700°C while maintaining the structural integrity needed to support the sample. Most importantly, they act as chemically neutral vessels, ensuring the reactor tube does not interfere with the pyrolysis process.

The reliability of your pyrolysis data hinges on the reactor tube acting as a completely neutral vessel; it must withstand intense heat without chemically interacting with the complex volatiles released by the sludge.

The Critical Role of Material Inertness

Preventing Chemical Interference

Oily sludge pyrolysis releases a complex mixture of volatile components. It is imperative that the reaction chamber material, specifically quartz or corundum, exhibits absolute chemical inertness.

If the tube material is reactive, it may interact with the pyrolysis vapors. This interaction alters the composition of the produced gases and liquids.

Maintaining Experimental Objectivity

The primary goal of using high-purity materials is to preserve the "objectivity" of your experimental results.

You need to measure the behavior of the sludge, not the behavior of the sludge reacting with the furnace wall. High-purity quartz and corundum ensure that the data collected reflects only the sample's decomposition.

Thermal Requirements and Stability

Withstanding High-Temperature Ranges

The pyrolysis of oily sludge typically occurs in a rigorous temperature window of 500°C to 700°C.

The core reaction chamber must possess exceptional thermal stability to endure these temperatures for extended periods.

Structural Integrity Under Load

Beyond just surviving the heat, the tube must physically support the sample holder and the sludge itself.

Materials like corundum and quartz retain their mechanical strength at these high temperatures, ensuring the chamber does not warp or collapse under the sample's weight.

Understanding the Risks of Material Compromise

The "Phantom Reaction" Trap

The most significant trade-off in selecting reactor materials is often between cost and purity. Lower-grade ceramics or metals might be cheaper, but they introduce the risk of catalytic effects.

If a material acts as an unintentional catalyst, it can skew reaction kinetics. This leads to false conclusions about the pyrolysis efficiency or product distribution.

Durability vs. Data Quality

While some materials may offer higher physical durability against impact, they often lack the chemical purity required for analytical pyrolysis.

Prioritizing physical toughness over chemical inertness can render an entire dataset invalid due to cross-contamination from the tube walls.

Making the Right Choice for Your Goal

Selecting the correct chamber material is about safeguarding the integrity of your chemical analysis.

- If your primary focus is experimental accuracy: Prioritize high-purity quartz to ensure maximum visibility and zero chemical interference with volatile components.

- If your primary focus is thermal durability: Choose corundum for its robust ability to handle the upper limits of the 700°C range without deformation.

Your equipment choices dictate your data quality; ensure your reactor chamber remains a silent observer, not an active participant in the chemical reaction.

Summary Table:

| Requirement | Specification | Benefit |

|---|---|---|

| Core Materials | High-purity Quartz or Corundum | Prevents chemical interference and catalytic effects |

| Thermal Range | 500°C to 700°C | Ensures structural integrity during sludge decomposition |

| Chemical Property | Absolute Inertness | Guarantees experimental data reflects only sample behavior |

| Mechanical Strength | High Structural Load Bearing | Supports sample holders without warping at peak heat |

Maximize Your Research Precision with KINTEK

Don’t let "phantom reactions" compromise your oily sludge pyrolysis data. KINTEK provides high-performance Tube, Muffle, and Vacuum furnace systems engineered for absolute chemical neutrality. Our expert R&D team delivers customizable solutions featuring high-purity quartz and corundum reaction chambers tailored to your specific temperature and purity needs.

Ready to upgrade your lab's thermal processing? Contact KINTEK today to discover how our advanced manufacturing can bring superior accuracy and durability to your research.

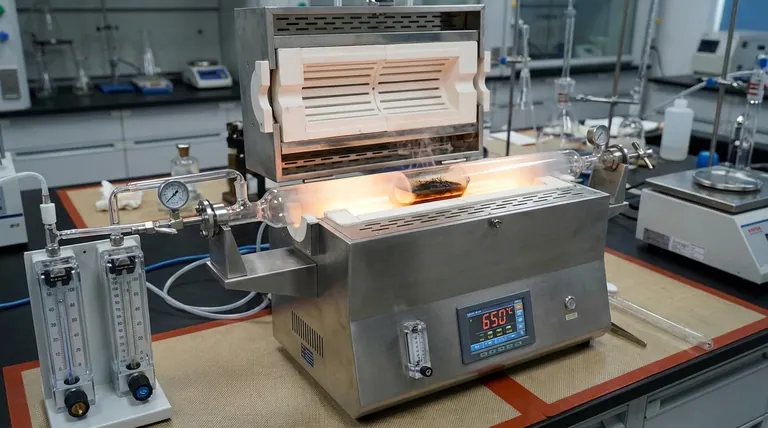

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the specific functions of the grinder and laboratory oven during sugarcane-based activated carbon preparation?

- Why is a Boron Nitride (BN) crucible ideal for high-temp graphite catalyst treatment? Ensure Purity & Sample Integrity

- Why is a high-purity quartz glass stirring rod used for phosphor dispersion? Key Benefits for Optical Glass Purity

- What functions do high-purity sulfur powder and ceramic boats serve in TB-MoS2 prep? Precision in 2D Material Synthesis

- What are the roles of laboratory vacuum drying ovens and precision analytical balances in moisture monitoring?

- Why are graphite crucible furnaces used in vacuum or protective atmosphere environments? Prevent Oxidation and Ensure Purity

- What is the primary function of a high-alumina powder crucible? Ensure Purity in Maraging Steel Pre-treatment

- What are the main composition percentages of alumina tubes? Optimize Performance for High-Temperature Applications