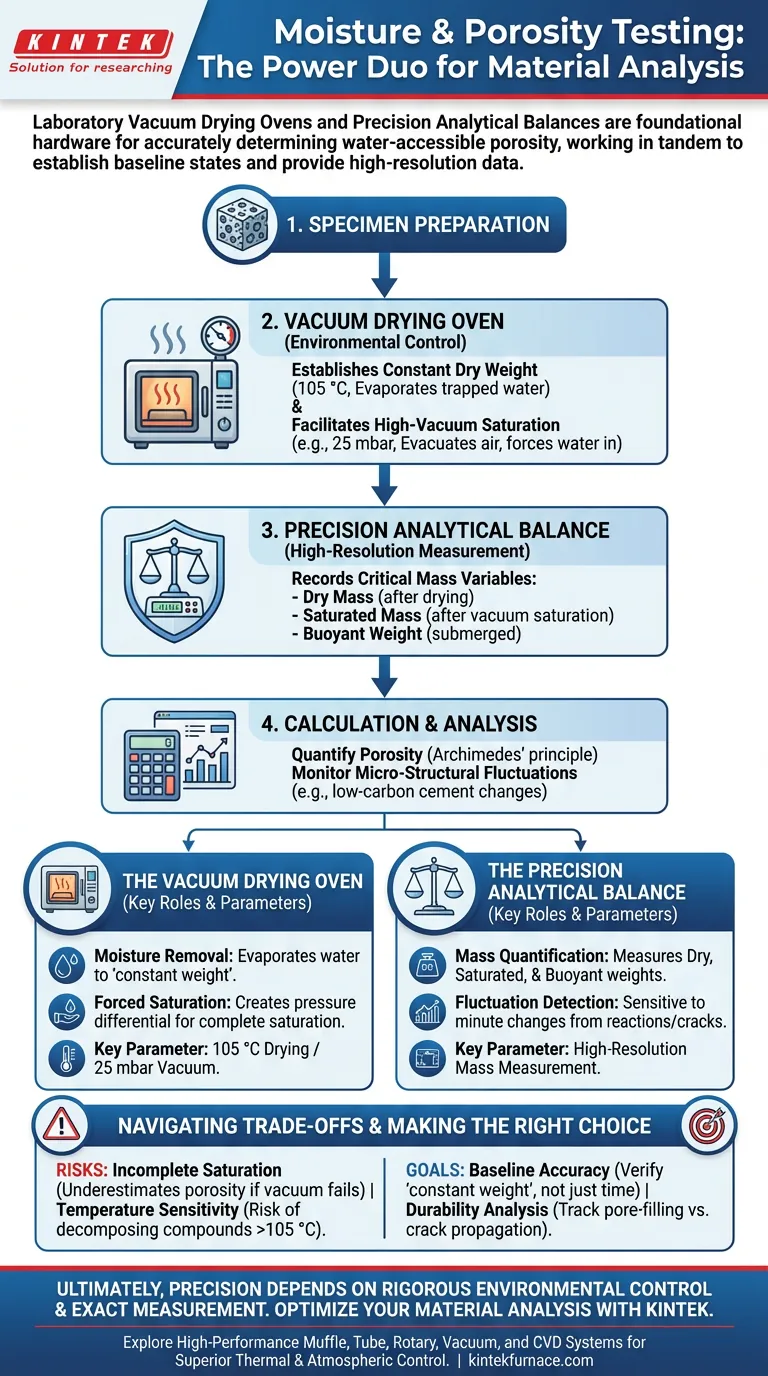

Laboratory vacuum drying ovens and precision analytical balances function as the foundational hardware for accurately determining water-accessible porosity. While the oven controls the environmental conditions to establish baseline states—specifically drying specimens and facilitating forced saturation—the balance provides the high-resolution data necessary to calculate density and void space.

Accurate porosity testing relies on calculating the precise difference between a material's completely dry state and its fully saturated state. These instruments work in tandem to manipulate and measure these extremes, enabling the quantification of micro-structural changes in materials like low-carbon cement.

The Role of the Vacuum Drying Oven

The vacuum drying oven is not merely a heating element; it is an environmental control chamber used to prepare specimens for testing.

Establishing Constant Dry Weight

The primary function of the oven in this context is to remove all moisture from sliced specimens.

By maintaining a temperature of 105 °C, the oven evaporates water trapped within the material's pores. The process continues until the specimen reaches a "constant weight," ensuring that the baseline mass used for calculations is free of variable moisture content.

Facilitating High-Vacuum Saturation

Beyond drying, the vacuum capabilities are essential for the saturation phase of porosity testing.

The reference highlights the use of high-vacuum forced water saturation (e.g., at 25 mbar). By evacuating air from the chamber and the specimen's pores, the oven creates a pressure differential that forces water deep into the material's matrix, ensuring complete saturation.

The Role of the Precision Analytical Balance

Once the physical states of the material are established by the oven, the precision analytical balance is used to quantify the results.

Recording Critical Mass Variables

To calculate porosity utilizing Archimedes' principle, the balance must record three specific measurements.

It measures the dry mass (after oven drying), the saturated mass (after vacuum saturation), and the buoyant weight (mass while submerged in water). These three data points are the mathematical inputs required to solve for volume and density.

Monitoring Micro-Structural Fluctuations

In the context of low-carbon cement matrices, the balance detects minute changes caused by chemical reactions.

The reference notes that these measurements reflect the fluctuation in porosity caused by sulfate attack. The balance must be sensitive enough to capture the physical competition between corrosion products filling the pores and the propagation of cracks which open new voids.

Understanding the Trade-offs

While this methodology is robust, accuracy depends heavily on strict adherence to procedure.

The Risk of Incomplete Saturation

If the vacuum pressure (e.g., 25 mbar) is not maintained or if the duration is insufficient, air pockets may remain in the matrix.

This leads to an underestimation of porosity, as the "saturated mass" will be lower than reality. The vacuum oven's performance is therefore the limiting factor in the accuracy of the saturation data.

Temperature Sensitivity

Drying at 105 °C is standard for removing free water, but it must be controlled carefully.

If the temperature fluctuates significantly higher, there is a risk of decomposing hydrated compounds within cementitious materials, which would artificially lower the dry mass and skew porosity calculations.

Making the Right Choice for Your Goal

To ensure reliable moisture and porosity data, align your procedure with your specific analytical objectives.

- If your primary focus is baseline accuracy: Ensure your drying protocol requires a "constant weight" verification rather than a fixed time duration, as drying rates vary by specimen density.

- If your primary focus is durability analysis: Pay close attention to the delta between pore-filling (mass gain) and crack propagation (volume increase), as this specific relationship indicates the stage of sulfate attack.

Ultimately, the precision of your porosity data is defined by the rigorous removal of air and water by the oven and the exact measurement of their displacement by the balance.

Summary Table:

| Instrument | Primary Function in Porosity Testing | Key Parameter/Metric |

|---|---|---|

| Vacuum Drying Oven | Moisture removal & forced water saturation | 105 °C drying / 25 mbar vacuum |

| Analytical Balance | High-resolution mass measurement | Dry, saturated, and buoyant weight |

| Combined Workflow | Quantification of micro-structural density | Total water-accessible porosity % |

Optimize Your Material Analysis with KINTEK

Precision in porosity and moisture monitoring starts with superior thermal and atmospheric control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique research requirements.

Whether you are studying low-carbon cement durability or advanced material matrices, our equipment ensures the stable environmental conditions necessary for accurate analytical data.

Ready to elevate your lab's capabilities? Contact us today to find your custom solution!

Visual Guide

References

- François El Inaty, Othman Omikrine Metalssi. Long-Term Effects of External Sulfate Attack on Low-Carbon Cementitious Materials at Early Age. DOI: 10.3390/app14072831

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Induction Melting Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the primary functions of high-purity graphite molds in the SPS of TiB2 ceramics? Enhance Sintering Precision

- What is the necessity of using a laboratory vacuum drying oven when processing Fe-N-C catalyst powders?

- What is the technical necessity of using a glass boat in a pyrolysis furnace? Precision in Thermal Decomposition

- What is the role of providing a uniform heating environment? Achieve Perfect Deep Eutectic Solvent Formation

- What role do contact thermocouples play during the high-temperature annealing experiments of oriented silicon steel?

- What are the advantages of using high-purity alumina crucibles? Achieve Precise Cast Iron Phase Equilibrium Data

- Why is a high vacuum pumping system required for Bi2Se3-Nd2Se3 alloying? Ensure Purity in Rare Earth Synthesis

- Why is vacuum sealing in high-purity quartz tubes necessary for the synthesis of FexTaSe2? Master Crystal Growth