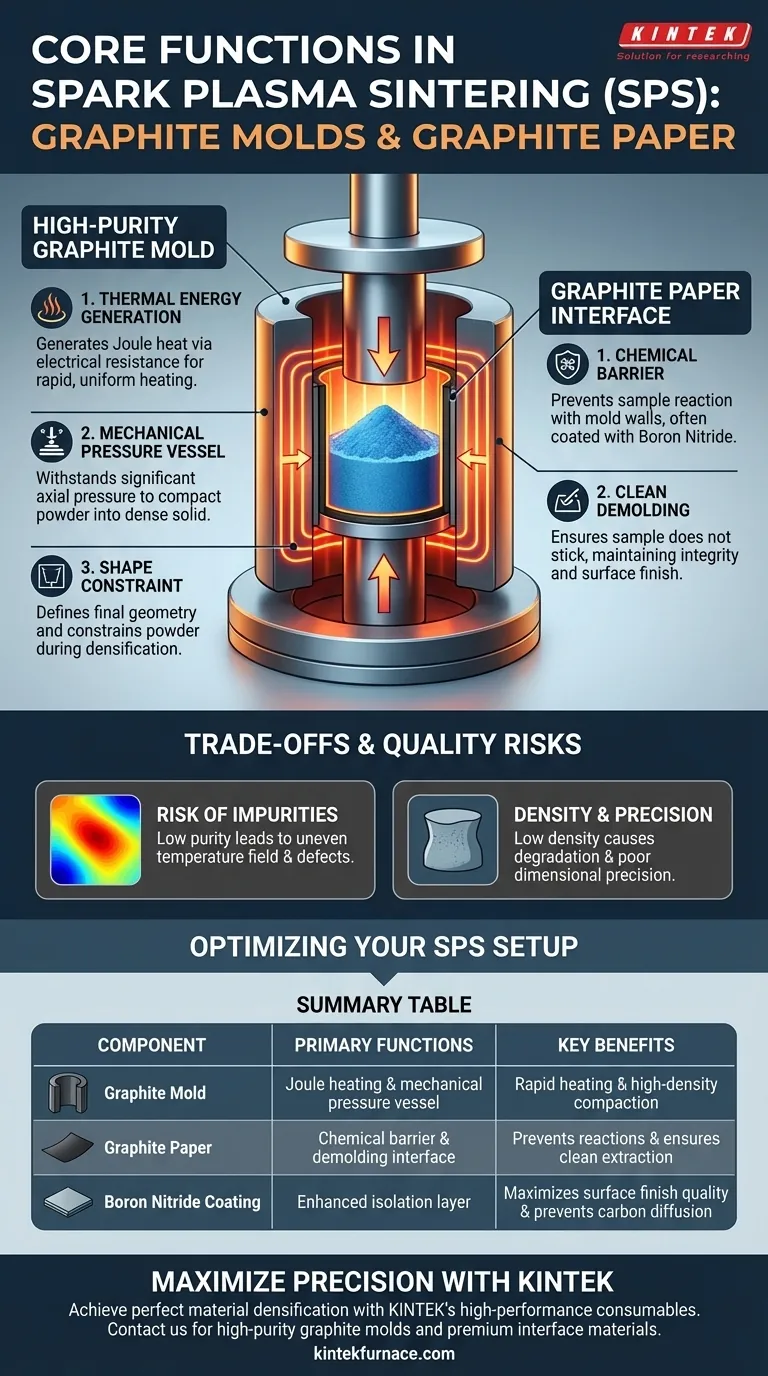

High-purity graphite molds and graphite paper are the functional backbone of Spark Plasma Sintering (SPS). The molds act simultaneously as the conductive heating element and the pressure vessel responsible for densifying the powder. Graphite paper serves as a critical protective interface, preventing the sample from chemically reacting with or bonding to the mold walls under extreme heat.

In the SPS process, the mold drives the sintering through Joule heating and mechanical compression, while the graphite paper preserves the sample’s chemical purity and structural integrity by acting as a non-reactive barrier.

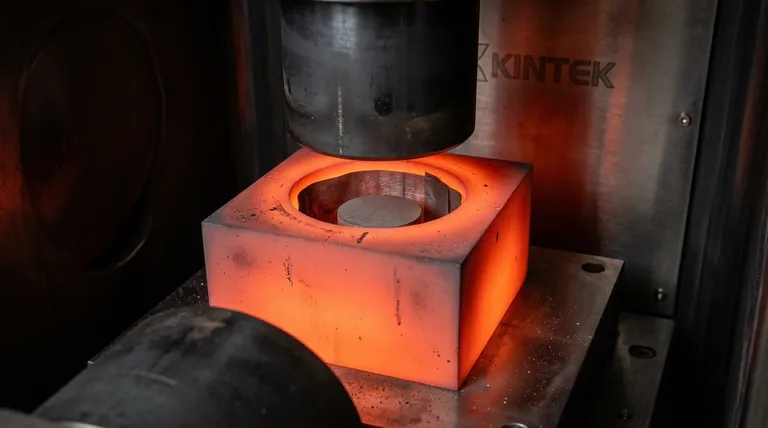

The Multifaceted Role of the Graphite Mold

Generating Thermal Energy

Unlike traditional sintering methods that use external heating elements, the graphite mold itself generates the heat.

It acts as part of the current circuit, utilizing its own electrical resistance to generate Joule heat when high current is passed through it.

This allows for rapid heating rates, as the thermal energy is generated in the immediate vicinity of the sample.

Transmitting Mechanical Pressure

The mold serves as a high-strength pressure vessel.

It must withstand significant unidirectional mechanical force (axial pressure) transmitted by the hydraulic cylinder.

This pressure is essential for compacting the ceramic or composite powder into a dense, solid form.

Constraining the Material Shape

The mold defines the final geometry of the sintered part.

It acts as a rigid carrier that constrains the loose powder into a specific shape during the densification process.

The Critical Function of Graphite Paper

Acting as a Chemical Barrier

Graphite paper lines the inner cavity of the mold to isolate the sample.

This layer helps prevent the sample powder—particularly metals or reactive ceramics—from reacting with the carbon in the mold walls.

The paper is often coated with boron nitride to further enhance this isolation and prevent diffusion.

Ensuring Clean Demolding

Without this interface, samples would likely adhere to the mold at high sintering temperatures.

The paper ensures the sample does not stick, allowing for smooth extraction after the process is complete.

This protection maintains the structural integrity of the sample and ensures a high-quality surface finish.

Understanding the Trade-offs

The Risk of Impurities

The performance of the process relies heavily on the quality of the graphite used.

If the graphite mold lacks sufficient purity, it can lead to an uneven temperature field during sintering.

This lack of uniformity can result in inconsistent material properties or defects in the final composite.

Density and Dimensional Precision

The density of the graphite mold directly correlates to the quality of the final product.

Lower-density graphite may degrade faster or deform under high pressure, compromising the dimensional precision of the sintered part.

Investing in high-density, high-strength graphite is often necessary to achieve tight tolerances and superior surface quality.

Optimizing Your SPS Setup

To achieve the best results in your sintering process, consider the specific requirements of your material and the quality of your consumables.

- If your primary focus is Temperature Uniformity: Prioritize high-purity, high-density graphite molds to ensure consistent electrical conductivity and an even thermal field.

- If your primary focus is Surface Quality and Integrity: Ensure you are using graphite paper, ideally coated with boron nitride, to completely eliminate adhesion and reaction risks.

By selecting the correct mold grade and interface materials, you ensure precise control over both the thermal and mechanical forces shaping your final product.

Summary Table:

| Component | Primary Functions | Key Benefits |

|---|---|---|

| Graphite Mold | Joule heating & mechanical pressure vessel | Rapid heating rates & high-density material compaction |

| Graphite Paper | Chemical barrier & demolding interface | Prevents sample-mold reactions & ensures clean extraction |

| Boron Nitride Coating | Enhanced isolation layer | Maximizes surface finish quality & prevents carbon diffusion |

Maximize Your Sintering Precision with KINTEK

Achieving perfect material densification requires high-performance consumables. Backed by expert R&D and manufacturing, KINTEK offers high-purity, high-strength graphite molds and premium interface materials designed for the rigors of Spark Plasma Sintering (SPS). Whether you are working with advanced ceramics or complex composites, our customizable solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—ensure uniform thermal fields and superior structural integrity.

Ready to elevate your lab's efficiency? Contact us today to find the perfect high-temperature solution for your needs!

Visual Guide

References

- Srinivasa Kartik Nemani, Babak Anasori. Ti <sub>3</sub> C <sub>2</sub> T <i> <sub>x</sub> </i> MXene‐Zirconium Diboride Based Ultra‐High Temperature Ceramics. DOI: 10.1002/advs.202500487

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- What is the function of a vacuum ampoule during the synthesis of ZnGeP2? Ensure Purity and Chemical Stability

- What is the maximum temperature for a quartz tube? Ensure Safe & Reliable High-Temp Processes

- Why is a vacuum rotary evaporator necessary for the liquid-phase deposition of nanosheets? Enhancing Cathode Performance

- Why Use Vacuum-Sealed Quartz Tubes for CVT CIPS Synthesis? Ensuring Purity and Precision

- What customization options are available for alumina ceramic tubes? Tailor for High-Temp, Corrosion-Resistant Applications

- What role does specialized graphite adhesive play? Expert Bonding Solutions for High-Temp Systems

- What is the primary role of laboratory furnaces in manufacturing and scientific processes? Unlock Precision Thermal Control

- Why is a vacuum filtration system necessary before evaluating activated carbon microspheres? Ensure Reliable Test Data