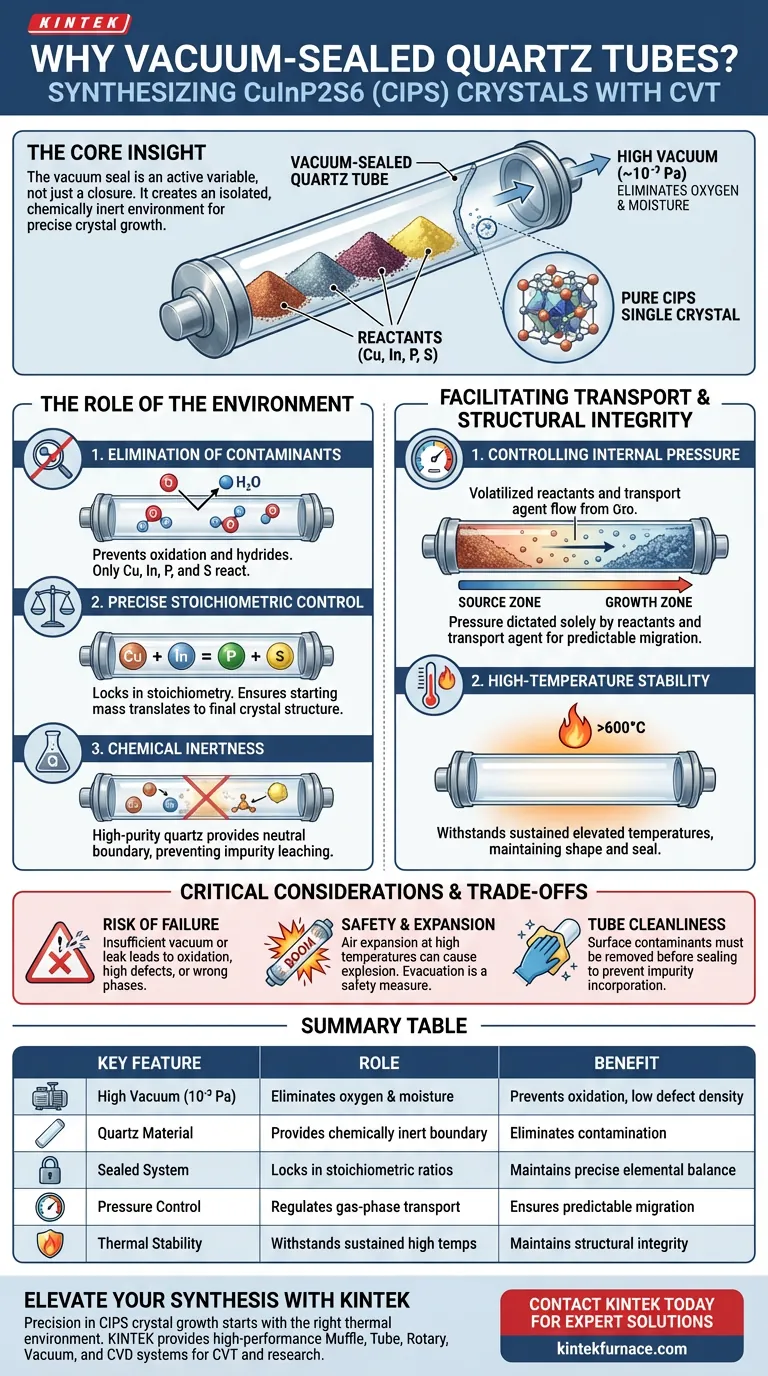

Vacuum-sealed quartz tubes are the critical reaction vessels for synthesizing CuInP2S6 (CIPS) because they create an isolated, chemically inert environment necessary for delicate crystal growth. By evacuating the tube to a high vacuum (approximately $10^{-3}$ Pa), the process completely eliminates oxygen and moisture, ensuring that the chemical reaction proceeds under precise stoichiometric conditions to yield high-quality, low-defect single crystals.

The Core Insight The vacuum seal is not merely a closure; it is an active variable in the synthesis process. It ensures the internal pressure is dictated solely by the reaction chemistry and transport agents, preventing oxidation from skewing the elemental ratios essential for forming pure CIPS crystals.

The Role of the Environment in CVT Synthesis

Elimination of Atmospheric Contaminants

The primary function of the vacuum seal is the total exclusion of oxygen and moisture.

Even trace amounts of air can lead to the oxidation of the raw materials before the reaction begins. By maintaining a high vacuum ($10^{-3}$ Pa), you ensure that the copper, indium, phosphorus, and sulfur react only with each other, rather than forming unwanted oxides or hydrides.

Precise Stoichiometric Control

High-quality CIPS crystals require a specific atomic ratio of elements.

If external gases infiltrate the system, they consume the reactants, shifting the chemical balance. The vacuum-sealed tube locks in the stoichiometry, ensuring that the starting mass of the reactants translates directly into the final crystal structure without deviation.

Chemical Inertness

Quartz is utilized because it provides a neutral physical boundary.

Unlike metal or other glass types, high-purity fused quartz does not react with the precursor materials or the transport agents at high temperatures. This prevents container-derived impurities from leaching into the CIPS crystal lattice, which is vital for minimizing material defects.

Facilitating the Transport Mechanism

Controlling Internal Pressure

The Chemical Vapor Transport (CVT) method relies on a transport agent moving gas-phase components across a temperature gradient.

Vacuum sealing removes atmospheric gases that would otherwise create erratic background pressure. This ensures the internal pressure is generated solely by the volatilized reactants and the transport agent, allowing for a predictable and controlled migration from the source zone to the growth zone.

Structural Integrity at High Temperatures

CVT synthesis occurs at elevated temperatures, often requiring thermal treatments that last for days.

Vacuum-sealed quartz tubes possess the thermal stability to withstand these sustained high temperatures (often exceeding $600^\circ$C). They maintain their structural shape and seal integrity, preventing the containment vessel from collapsing or rupturing during the growth cycle.

Critical Considerations and Trade-offs

The Risk of Vacuum Failure

The quality of the crystal is entirely dependent on the quality of the seal.

If the vacuum level is insufficient (higher than $10^{-3}$ Pa) or if the seal leaks, the "closed system" assumption fails. This immediately leads to oxidation of the reactants, resulting in crystals with high defect densities or entirely different chemical phases.

Safety and Gas Expansion

Proper evacuation is also a critical safety measure.

If air is left inside the tube, it will expand rapidly when heated to synthesis temperatures. This expansion can cause the quartz tube to explode due to excessive internal pressure. Evacuating the tube minimizes this risk by removing the non-reactive gas load.

Tube Cleanliness

The quartz tube itself must be scrupulously clean before sealing.

While the vacuum removes air, it cannot remove surface contaminants left on the inner wall of the tube. Any residual impurities inside the tube will be incorporated into the crystal, degrading its intrinsic properties.

Making the Right Choice for Your Goal

To maximize the success of your CIPS synthesis, align your setup with your specific experimental objectives:

- If your primary focus is Crystal Purity: Ensure your vacuum system reliably reaches $10^{-3}$ Pa or lower to completely eliminate oxidation risks.

- If your primary focus is Defect Reduction: Use high-purity quartz and verify the tube's internal cleanliness to prevent wall-based contaminants from acting as nucleation sites.

- If your primary focus is Process Safety: Verify the vacuum seal integrity prior to heating to prevent pressure-based explosions during the high-temperature ramp.

The vacuum-sealed quartz tube is the guarantor of purity, transforming a volatile chemical reaction into a controlled, high-precision crystal growth process.

Summary Table:

| Key Feature | Role in CIPS Synthesis | Benefit for Crystal Quality |

|---|---|---|

| High Vacuum ($10^{-3}$ Pa) | Eliminates oxygen and moisture | Prevents oxidation and ensures low defect density |

| Quartz Material | Provides chemically inert boundary | Eliminates contamination from the reaction vessel |

| Sealed System | Locks in stoichiometric ratios | Maintains precise elemental balance for pure crystals |

| Pressure Control | Regulates gas-phase transport | Ensures predictable migration from source to growth zone |

| Thermal Stability | Withstands sustained high temps | Maintains structural integrity during long growth cycles |

Elevate Your Material Synthesis with KINTEK

Precision in CuInP2S6 (CIPS) crystal growth starts with the right thermal environment. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigors of Chemical Vapor Transport. Whether you need a standard setup or a customizable high-temperature furnace to meet unique research specifications, our equipment ensures the stability and control your lab requires.

Ready to optimize your crystal growth process? Contact KINTEK today for expert solutions!

Visual Guide

References

- Xingan Jiang, Weiyou Yang. Dual-role ion dynamics in ferroionic CuInP2S6: revealing the transition from ferroelectric to ionic switching mechanisms. DOI: 10.1038/s41467-024-55160-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why are support frames important for the alumina furnace tube? Prevent High-Temperature Deformation and Failure

- Why use graphite or quartz crucibles for liquid antimony-tellurium? Protect Your High-Temp Melt Integrity

- Why are high-purity quartz tubes and quartz boats preferred for plastic pyrolysis? Ensure Precise, Pure Results

- Why is a vacuum pump utilized in research concerning the reaction of magnesium with carbon dioxide and nitrogen? Ensure Data Integrity

- What is the function of high-purity alumina crucibles? Achieve Precise Results in Pyroprocessing Salt Research

- What is the function of a graphite plate in microwave cladding? Ensure Purity & Thermal Uniformity for HEA Synthesis

- What advantages does a vacuum drying oven offer for BiFeO3 electrode sheets? Optimize Your Battery Research

- Why are coating samples placed in specialized crucibles? Ensure Accurate Molten Salt Corrosion Testing Results