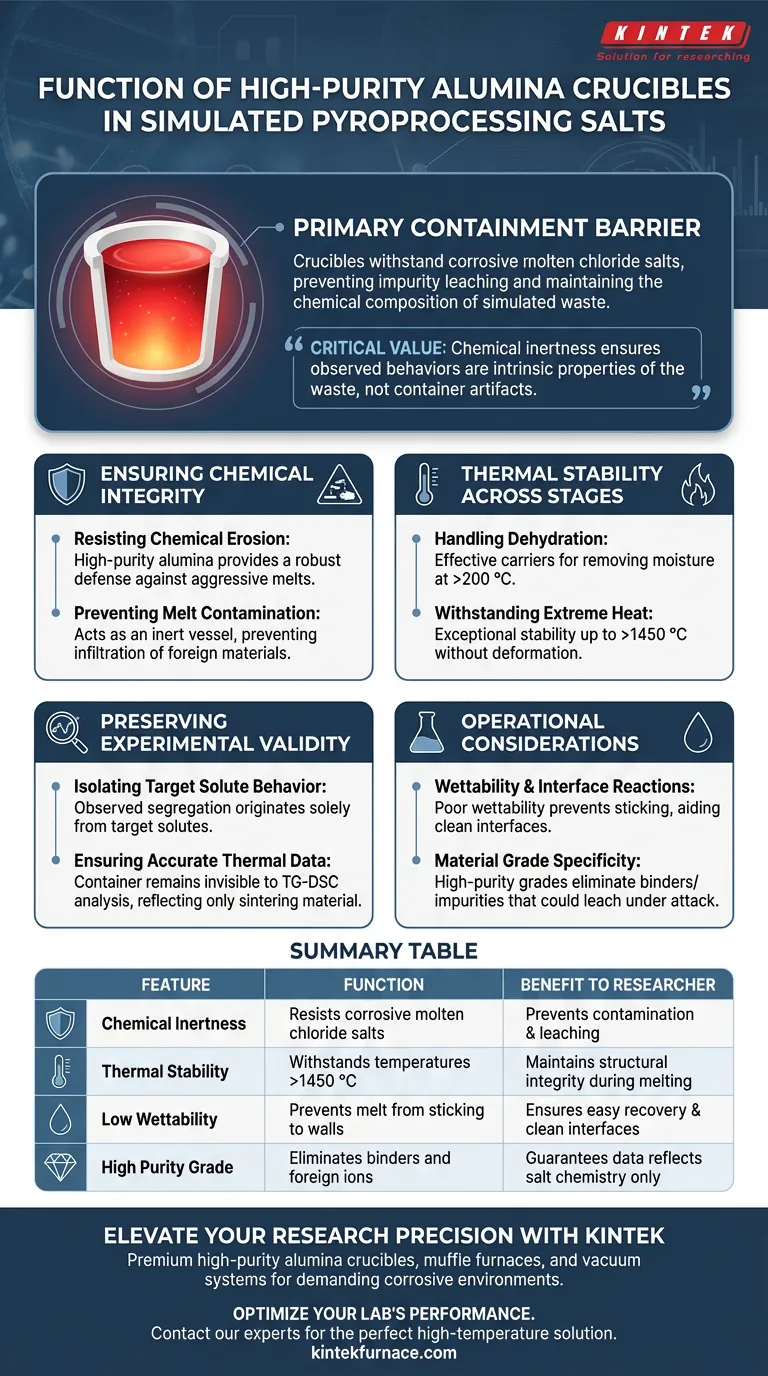

High-purity alumina crucibles serve as the primary containment barrier against contamination during the severe conditions of pyroprocessing research. Their fundamental function is to withstand the corrosive nature of molten chloride salts while preventing the leaching of impurity ions into the mixture, ensuring that the chemical composition of the simulated waste remains unaltered.

The critical value of high-purity alumina lies in its chemical inertness; it ensures that any observed physical behaviors or segregation in the melt are intrinsic properties of the waste form itself, rather than artifacts caused by a reaction with the container.

Ensuring Chemical Integrity in Corrosive Environments

Resisting Chemical Erosion

Molten salts, particularly chloride mixtures used in pyroprocessing, are highly corrosive agents.

High-purity alumina provides a robust defense against this chemical erosion. It prevents the aggressive melt from eating away at the crucible walls, which is essential for maintaining physical containment during prolonged heating.

Preventing Melt Contamination

The validity of a simulated waste experiment depends entirely on purity.

If a crucible degrades, it releases impurity ions into the melt. High-purity alumina acts as an inert vessel, preventing the infiltration of foreign materials that would alter the chemical baseline of the simulated salt.

Thermal Stability Across Processing Stages

Handling Dehydration and Purification

Before melting occurs, hygroscopic salts (such as the Magnak mixture) must be dehydrated to remove moisture.

Alumina crucibles are effective carriers during this initial stage, protecting the raw materials during dehydration at temperatures exceeding 200 °C. This prevents the salts from reacting with the external atmosphere while moisture is purged.

Withstanding Extreme Heat

The melting and sintering phases of pyroprocessing require temperatures far beyond the dehydration point.

Alumina crucibles offer exceptional thermal stability, capable of withstanding temperatures exceeding 1450 °C. This ensures the vessel retains its structural integrity without softening or deforming during the high-heat phases of preparation.

Preserving Experimental Validity

Isolating Target Solute Behavior

In pyroprocessing research, scientists often look for specific "segregation behaviors"—how elements separate or move within the salt.

Because alumina is chemically inert, it ensures that these observed behaviors originate solely from the target solutes. There is no interference from the container wall to skew the data.

Ensuring Accurate Thermal Data

When performing thermal analyses like Thermogravimetric-Differential Scanning Calorimetry (TG-DSC), the container must be invisible to the data.

Alumina's stability ensures that the heat changes recorded reflect the sintering material itself. It prevents false readings that could arise from container-sample reactions.

Operational Considerations and Trade-offs

Wettability and Interface Reactions

While generally inert, the interaction between the melt and the crucible wall is a critical variable.

Alumina typically exhibits poor wettability, which is advantageous as it prevents the melt from sticking to or climbing the walls. However, researchers must verify that this non-wetting property aligns with their specific salt mixture to ensure reactions occur only where intended (e.g., at specific experimental interfaces).

Material Grade Specificity

Not all alumina is created equal.

For these specific applications, high-purity grades are non-negotiable. Lower-grade alumina may contain binders or impurities that could leach out under the attack of molten chlorides, negating the benefits of the material.

Making the Right Choice for Your Goal

To maximize the reliability of your simulated pyroprocessing data, select your crucible based on your specific analytical needs:

- If your primary focus is Chemical Segregation Studies: Prioritize high-purity alumina to ensure that element separation is a result of the salt chemistry, not container leaching.

- If your primary focus is Thermal Analysis (TG-DSC): Rely on alumina's thermal stability to prevent background noise or reaction peaks from the container material.

- If your primary focus is Moisture Removal: Use these crucibles as a stable carrier for dehydration processes >200 °C to prevent atmospheric contamination.

Ultimately, the high-purity alumina crucible acts as a silent guarantor of truth, ensuring your data reflects the chemistry of the salt rather than the limitations of the hardware.

Summary Table:

| Feature | Function in Pyroprocessing | Benefit to Researcher |

|---|---|---|

| Chemical Inertness | Resists corrosive molten chloride salts | Prevents melt contamination & leaching |

| Thermal Stability | Withstands temperatures >1450 °C | Maintains structural integrity during melting |

| Low Wettability | Prevents melt from sticking to walls | Ensures easy sample recovery & clean interfaces |

| High Purity Grade | Eliminates binders and foreign ions | Guarantees data reflects salt chemistry only |

Elevate Your Research Precision with KINTEK

Don't let container contamination compromise your experimental integrity. Backed by expert R&D and manufacturing, KINTEK offers premium high-purity alumina crucibles, muffle furnaces, and vacuum systems designed to withstand the most demanding corrosive environments. Whether you are conducting chemical segregation studies or high-temperature thermal analysis, our customizable lab solutions provide the thermal stability and chemical inertness your project requires.

Ready to optimize your lab's performance? Contact our technical experts today to find the perfect high-temperature solution for your unique needs.

Visual Guide

References

- Alex Scrimshire, Paul A. Bingham. Benchtop Zone Refinement of Simulated Future Spent Nuclear Fuel Pyroprocessing Waste. DOI: 10.3390/ma17081781

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What factors affect the light transmittance of alumina tubes? Balance Clarity and Durability for Your Lab

- What are the advantages of using high-purity quartz boats? Ensure Purity in Carbon Nanotube Synthesis

- What are the secondary functions of high-purity graphite molds? Unlocking Advanced Sintering Capabilities

- How does a PID temperature controller facilitate gasification research? Unlock Precision in Industrial Simulations

- What function does a laboratory blast drying oven perform? Optimize Pretreatment for Magnetic Particles

- How does choosing alumina vs graphite crucibles affect Al-Si melting? Expert Guide to Data Integrity

- What is the primary function of a radiation pyrometer in validating furnace simulations? Ensure Model Accuracy

- Why use sealed quartz tubes & vacuum for Mg-Zn/Mg-Cd alloy prep? Ensure Compositional Purity