At its core, a laboratory furnace is an instrument for creating a precisely controlled thermal environment. Its primary role is to apply specific, often extreme, temperatures to a material to induce predictable physical changes or chemical reactions. This capability is fundamental for ensuring quality control in manufacturing and enabling new discoveries in scientific research.

The true value of a laboratory furnace lies not merely in its ability to generate heat, but in its capacity for precision and repeatability. By mastering the control of temperature, atmosphere, and time, these devices allow scientists and engineers to reliably transform materials, ensuring consistent product quality and enabling the development of advanced technologies.

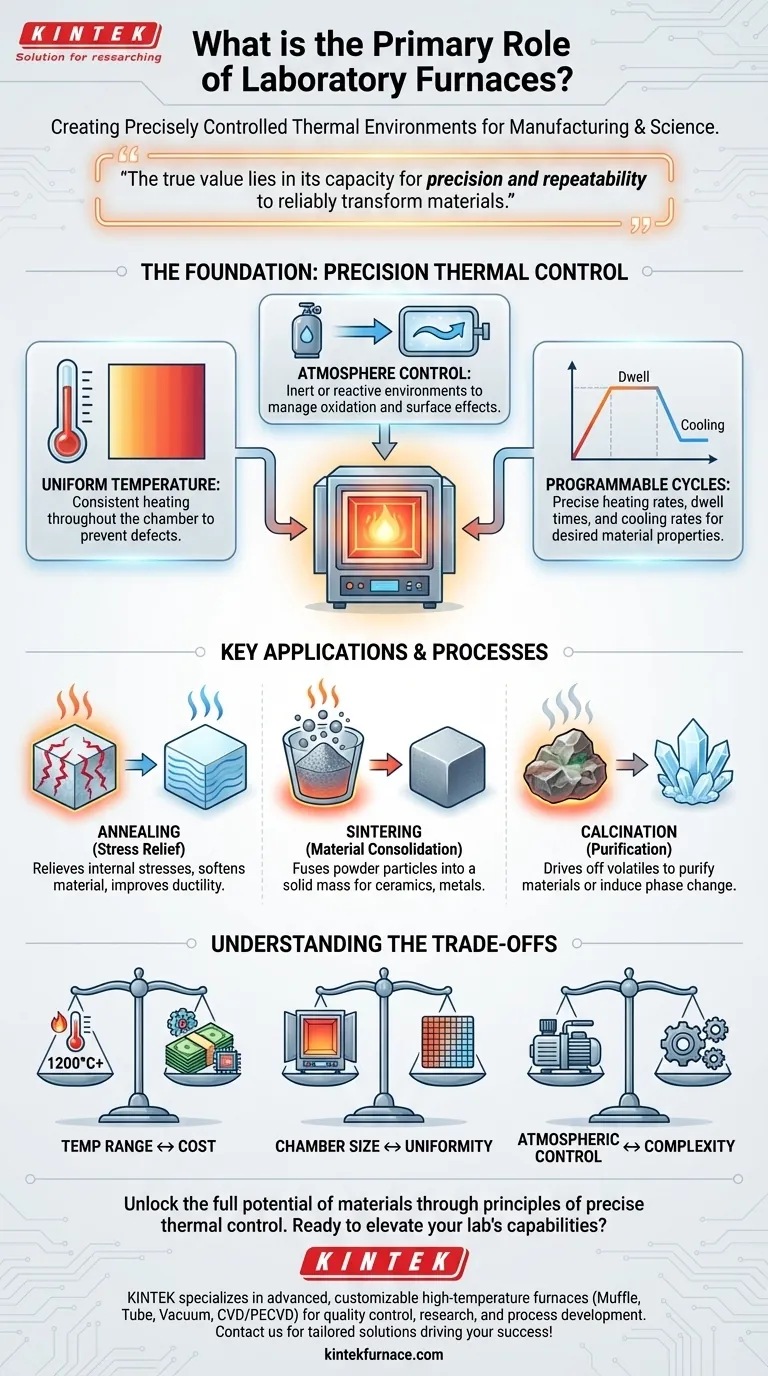

The Foundation: Precision Thermal Control

The effectiveness of any furnace-based process hinges on its ability to control vriendly variables. Heat alone is insufficient; it is the quality of that heat that dictates the outcome.

Achieving Uniform Temperature

A critical requirement is temperature uniformity, meaning the entire volume of the furnace chamber is at the same temperature. This ensures that a material or component is treated evenly, preventing weak spots, internal stresses, or inconsistent properties.

Inconsistent heating can ruin a sample, rendering test results invalid or creating a defective part.

Controlling the Atmosphere

Many material transformations are highly sensitive to the surrounding atmosphere. Furnaces provide control over this crucial variable.

An inert atmosphere, using gases like argon or nitrogen, is used to prevent oxidation or other unwanted reactions when heating metals. Conversely, a reactive atmosphere may be introduced температура to deliberately create a surface effect, like in carburizing steel.

Programmable Heating and Cooling

The rate at which a material is heated, the time it is held at a peak temperature (dwell time), and the rate at which it is cooled are just as important as the temperature itself.

Modern furnaces allow for precise programming of these thermal cycles. This control is essential for processes like annealing, where slow cooling is required to maximize a material's ductility.

Key Applications and Processes

The precise thermal control offered by laboratory furnaces enables several foundational processes across science and industry.

Annealing for Stress Relief

Annealing involves heating a material to a specific temperature and then cooling it slowly. This process relieves internal stresses, softens the material, and improves its ductility, making it less brittle and easier to work with.

It is a vital step in metallurgy and glass manufacturing to ensure a final product's durability.

Sintering for Material Consolidation

Sintering is the process of taking a powdered material and heating it to just below its melting point. At this temperature, the particles fuse, forming a solid or porous mass.

This technique is essential for creating components from ceramics, metals, and polymers, and is widely used in the aerospace, electronics, and medical implant industries.

Calcination for Purification

Calcination involves heating a material to a high temperature to drive off volatile substances, such as water or carbon dioxide, causing it to decompose or undergo a phase transition.

This is a fundamental process in the production of cement, the removal of water from hydrated minerals, and the purification of various chemical compounds.

Understanding the Trade-offs

Selecting or operating a furnace involves balancing competing priorities. Understanding these trade-offs is key to making sound technical and financial decisions.

Temperature Range vs. Cost

The maximum achievable temperature廣告 has the single greatest impact on a furnace's cost. Furnaces capable of exceeding 1200°C require exotic heating elements (like molybdenum disilicide) and advanced insulation, leading to a significant increase in price and operating expense.

Chamber Size vs. Uniformity

As the internal chamber volume increases, it becomes exponentially more difficult and energy-intensive to maintain tight temperature uniformity. A large furnace идеальный for processing many samples at once may not be suitable for research that demands a highly precise thermal environment.

Atmospheric Control vs. Complexity

A simple furnace that operates in ambient air is straightforward and reliable. Introducing capabilities for vacuum or controlled gas flow adds significant complexity, cost, and potential points of failure, including seals, pumps, and gas mixing systems.

Making the Right Choice for Your Goal

Your specific objective should dictate your choice of equipment and process parameters.

- If your primary focus is quality control and material testing: Prioritize furnaces with excellent temperature uniformity and data logging to ensure your results are repeatable and verifiable.

- If your primary focus is advanced materials research: Your highest priorities should be a wide temperature range and precise atmospheric control to enable the synthesis of novel materials.

- If your primary focus is process development or small-scale production: Balance chamber size, energy consumption, and the level of thermal precision vaše your specific process requires.

By moving beyond the simple concept of "heating" and focusing on the principles of precise thermal control, you unlock the full potential of your materials and processes.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Role | Apply precise temperatures to induce physical/chemical changes in materials. |

| Key Features | Temperature uniformity, atmospheric control, programmable heating/cooling. |

| Common Applications | Annealing, sintering, calcination for stress relief, material consolidation, purification. |

| Trade-offs | Temperature range vs. cost, chamber size vs. uniformity, atmospheric control vs. complexity. |

Ready to elevate your lab's capabilities with precision thermal solutions? KINTEK specializes in advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring reliable performance for quality control, materials research, or process development. Contact us today to discuss how our tailored furnace solutions can drive your success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis