For most applications, a standard fused quartz tube has a continuous maximum working temperature of approximately 1100°C (2012°F). While it can technically withstand brief excursions up to 1200°C (2192°F), operating consistently above 1100°C dramatically shortens its lifespan and introduces significant risks of failure.

The most critical factor to understand is not the melting point of quartz, but its devitrification temperature. Pushing a quartz tube beyond 1100°C for extended periods causes it to become brittle and opaque, compromising its structural integrity and the purity of your process.

The Role of Quartz in High-Temperature Applications

Quartz is the default choice for many high-temperature processes, such as in tube furnaces, for several key reasons. Understanding these properties helps clarify its limitations.

Exceptional Thermal Shock Resistance

Quartz has a very low coefficient of thermal expansion. This means it can withstand rapid temperature changes without cracking, a crucial property for furnace operations.

High Purity and Chemical Inertness

Fused quartz is exceptionally pure (often 99.99% SiO₂), ensuring that the tube itself does not become a source of contamination for the materials or chemical reactions being studied inside it.

Optical Clarity

The transparency of quartz allows for direct visual observation of the process, which can be invaluable for research and process monitoring.

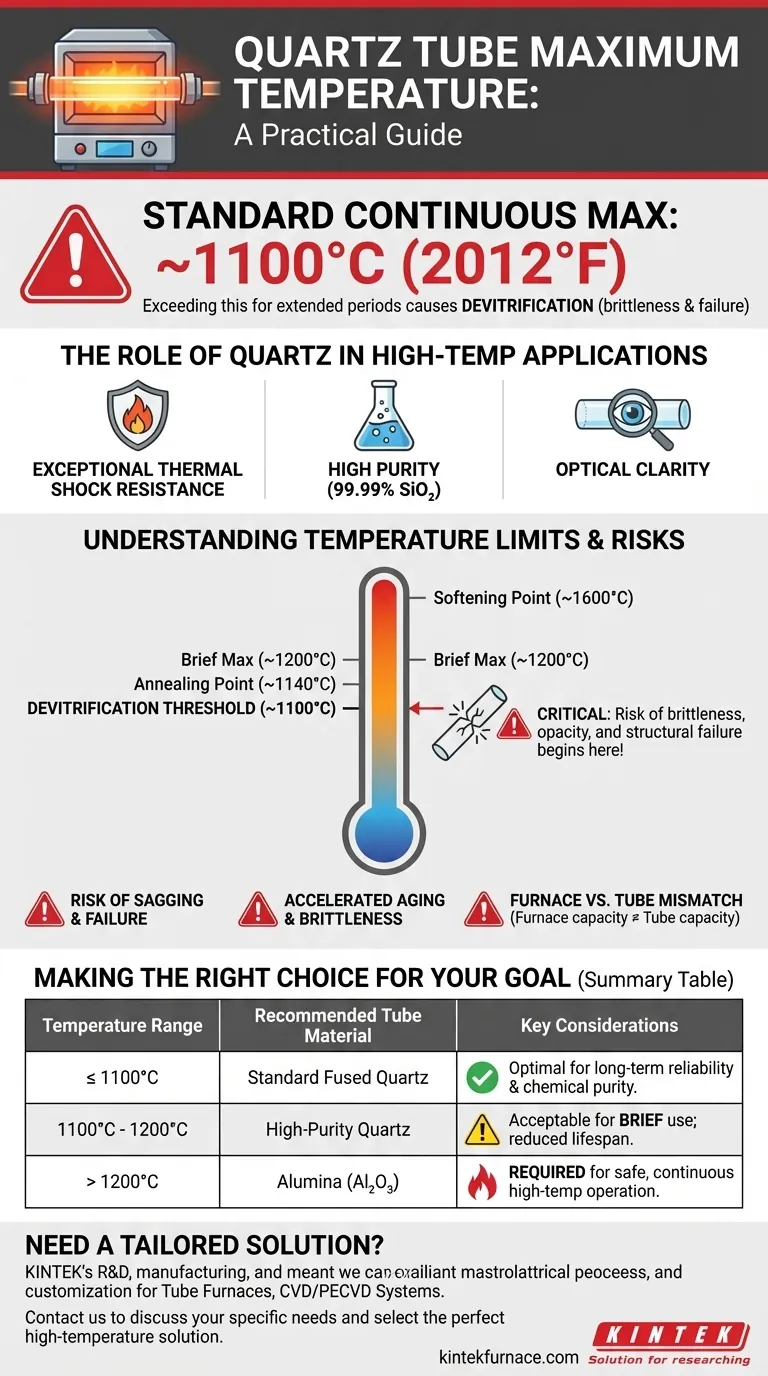

Understanding Quartz Temperature Limits

The "maximum temperature" of quartz is not a single number but a series of thresholds that dictate its practical use.

The Softening Point (~1600°C)

This is the temperature at which quartz begins to lose its shape and deform under its own weight. It is a theoretical limit, not a safe operating temperature.

The Annealing Point (~1140°C)

At this temperature, internal stresses within the quartz can be relieved very quickly. Operating near or above this point for long periods can lead to sagging and deformation.

The Critical Threshold: Devitrification (~1100°C)

This is the single most important practical limitation. Devitrification is a process where the amorphous, glass-like structure of quartz begins to crystallize into a form called cristobalite.

This transformation is highly undesirable because the crystallized areas are opaque, have a different thermal expansion rate, and become extremely brittle upon cooling. This leads to tube failure.

Understanding the Trade-offs and Risks

Using a quartz tube near its limit is a trade-off between performance and equipment longevity.

Risk of Sagging and Failure

If a furnace is run continuously above 1100°C, the quartz tube will eventually begin to sag, especially over longer, unsupported spans. This structural failure can ruin an experiment and damage the furnace.

Accelerated Aging and Brittleness

Every heating cycle above 1100°C contributes to devitrification. A tube that looks fine when hot may reveal micro-cracks or milky, opaque patches after cooling, indicating it has become brittle and is no longer safe to use.

The "Furnace vs. Tube" Mismatch

Many high-temperature furnaces are capable of reaching 1500°C or even 1800°C. A common and costly mistake is assuming the standard quartz tube included with or purchased for the furnace can handle these temperatures. The tube is almost always the limiting component.

Making the Right Choice for Your Goal

Always select your process tube based on your required operating temperature, not the maximum capability of your furnace.

- If your primary focus is working at or below 1100°C: A standard fused quartz tube is the most reliable and cost-effective choice for your application.

- If you need to briefly exceed 1100°C (up to 1200°C): Use a high-purity quartz tube, but budget for a significantly shortened lifespan and inspect it for signs of devitrification after every use.

- If your primary focus is working above 1200°C: You must use a ceramic alternative, such as an Alumina (Al₂O₃) tube, which can safely operate at temperatures up to 1700°C or higher.

Matching your tube material to your process temperature is the most critical factor for ensuring safe, repeatable, and successful results.

Summary Table:

| Temperature Range | Recommended Tube Material | Key Considerations |

|---|---|---|

| ≤ 1100°C | Standard Fused Quartz | Optimal for long-term reliability and chemical purity. |

| 1100°C - 1200°C | High-Purity Quartz | Acceptable for brief use; expect reduced tube lifespan. |

| > 1200°C | Alumina (Al₂O₃) | Required for safe, continuous operation at high temperatures. |

Need a High-Temperature Furnace Solution Tailored to Your Process?

Choosing the right furnace and tube material is critical for the safety and success of your high-temperature applications. KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced solutions.

Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities. We can precisely engineer systems to meet your unique temperature and material requirements, ensuring optimal performance and longevity.

Contact us today to discuss your specific needs and let our experts help you select or customize the perfect high-temperature solution.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation