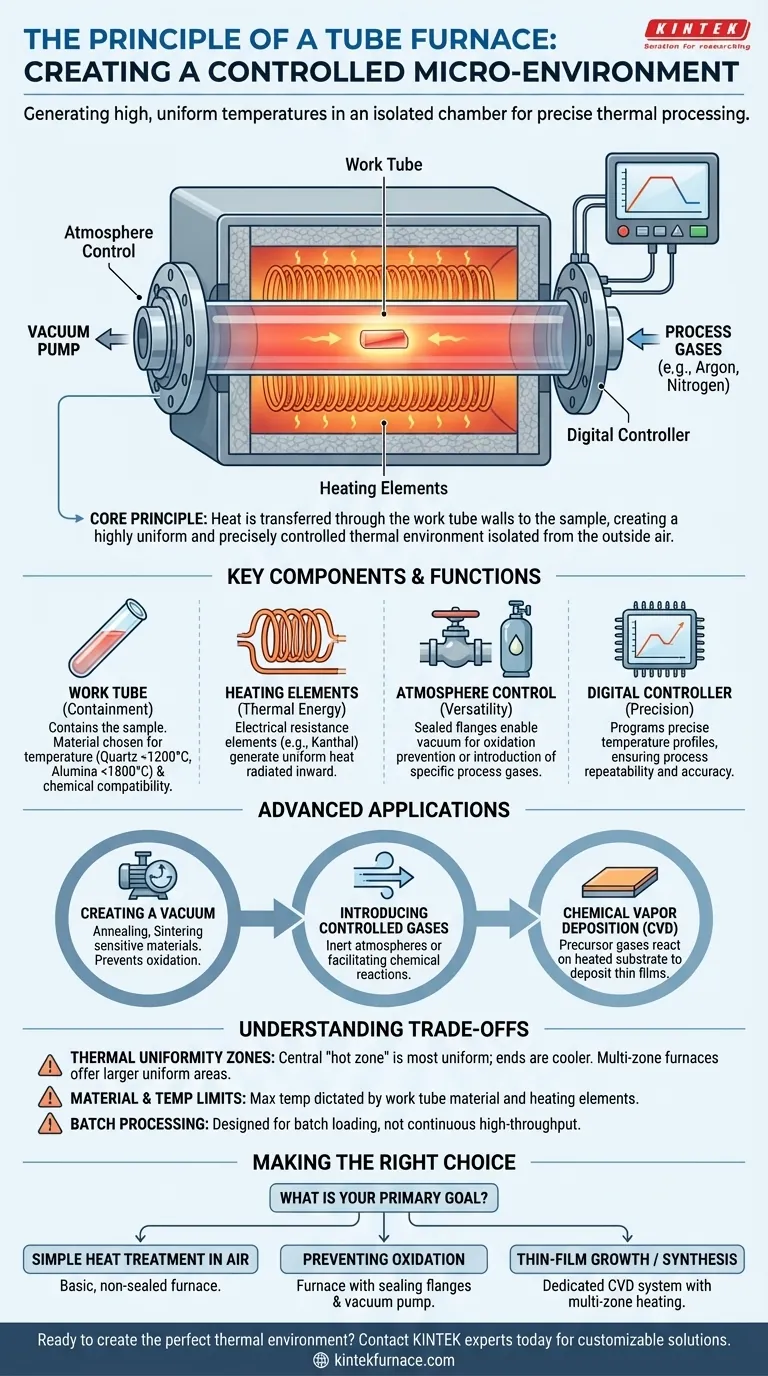

At its core, the principle of a tube furnace is remarkably straightforward. It operates by generating high temperatures in a chamber that surrounds a central, hollow tube. The heat is transferred through the walls of this tube to a sample placed inside, creating a highly uniform and precisely controlled thermal environment isolated from the outside air.

The true function of a tube furnace isn't just to generate heat, but to create a contained, controllable micro-environment. This ability to isolate a sample and manipulate its atmosphere—whether by creating a vacuum or introducing specific gases—is what makes it an indispensable tool in science and engineering.

How a Tube Furnace Achieves Control

A tube furnace functions through the interaction of a few critical components, each serving a distinct purpose in achieving a stable and isolated heating process.

The Work Tube: The Heart of the System

The sample is placed inside the work tube, which acts as the primary containment vessel. The material of this tube is chosen based on the required temperature and chemical environment.

Common materials include quartz, which is excellent for its chemical purity and visibility up to ~1200°C, and alumina or corundum, which are used for higher temperatures (up to 1800°C) and greater durability.

Heating Elements: The Source of Thermal Energy

Modern laboratory tube furnaces primarily use electrical resistance heating elements. These elements, often made of materials like Kanthal or silicon carbide, are wrapped around the exterior of the work tube.

When electrical current passes through them, they generate intense, uniform heat that radiates inward, heating the tube and the sample within it. Some industrial-scale furnaces may use fuel combustion, but electrical resistance offers far more precise control.

Atmosphere Control: The Key to Versatility

The defining feature of a tube furnace is its ability to control the atmosphere inside the work tube. By sealing both ends with specialized flanges, the internal environment can be completely isolated.

This setup allows an operator to either pump the air out to create a vacuum, preventing unwanted oxidation, or to introduce a continuous flow of specific process gases, such as inert argon or reactive gases for chemical synthesis.

The Controller: The Brain of the Operation

The entire process is governed by a digital controller. This unit allows the user to program precise temperature profiles, including the ramp-up rate, the dwell time at a target temperature, and the cooling rate. This ensures process repeatability and accuracy.

The Principle in Action: Advanced Applications

This fundamental principle of isolated heating enables a wide range of sophisticated processes that are impossible in a standard oven.

Creating a Vacuum Environment

By connecting a vacuum pump to one of the sealed flanges, all air and moisture can be removed from the tube. This is critical for processes like annealing or sintering sensitive materials that would be damaged or contaminated by reacting with oxygen at high temperatures.

Introducing Controlled Gases

Once a vacuum is established, specific gases can be introduced through a gas inlet. This allows for creating a completely inert atmosphere (using argon or nitrogen) or for facilitating specific chemical reactions on the sample's surface.

Chemical Vapor Deposition (CVD)

CVD is a perfect example of the tube furnace's power. In this process, precursor gases are flowed through the heated tube over a substrate. The high temperature provides the energy for the gases to react and deposit a thin film of solid material onto the substrate, enabling the creation of advanced electronics and coatings.

Understanding the Trade-offs

While powerful, a tube furnace is not a universal solution. Understanding its limitations is key to using it effectively.

Thermal Uniformity Zones

Heat naturally escapes from the ends of the tube, creating a central "hot zone" with a highly uniform temperature. The areas near the ends will be slightly cooler. For processes requiring exceptional uniformity over a larger area, more complex and costly multi-zone furnaces with independent heating elements are used.

Material and Temperature Limits

The furnace's maximum operating temperature is limited by its heating elements and insulation. More importantly, the work tube material dictates the practical limits. A quartz tube cannot be used at temperatures where an alumina tube is required, and certain chemicals may react with the tube itself at high temperatures.

Batch Processing, Not Continuous Flow

Tube furnaces are inherently batch-processing tools. Samples are loaded, processed, cooled, and then removed. They are not designed for the kind of high-throughput, continuous production seen in large-scale industrial manufacturing.

Making the Right Choice for Your Goal

Your application will determine the type of tube furnace system you need.

- If your primary focus is simple heat treatment in air: A basic, non-sealed tube furnace provides excellent temperature control for straightforward processes.

- If your primary focus is preventing oxidation: A furnace system with sealing flanges and a vacuum pump is essential for creating a clean, oxygen-free environment.

- If your primary focus is thin-film growth or advanced synthesis: A dedicated CVD system with multiple gas flow controllers and multi-zone heating is required to manage complex chemical reactions.

Understanding that a tube furnace is an environmental chamber, not just an oven, is the key to unlocking its full potential for materials innovation.

Summary Table:

| Component | Function & Key Feature |

|---|---|

| Work Tube | Contains the sample; made of quartz (up to 1200°C) or alumina (up to 1800°C). |

| Heating Elements | Generate uniform heat via electrical resistance (e.g., Kanthal) around the tube. |

| Atmosphere Control | Sealed flanges enable vacuum or specific gas flows (inert/reactive) inside the tube. |

| Digital Controller | Programs precise temperature profiles (ramp, dwell, cool) for repeatable results. |

Ready to create the perfect thermal environment for your research or production?

At KINTEK, we understand that your success depends on precise, reliable, and customizable thermal processing. Our advanced high-temperature tube furnaces are engineered with exceptional R&D and in-house manufacturing to deliver the exact performance your laboratory requires.

Whether you need standard configurations or deep customizations for unique experimental setups—including vacuum systems, gas flow control, or multi-zone heating—KINTEK has the solution.

Let's discuss your specific application needs. Contact our experts today to explore how our tube furnaces can accelerate your materials innovation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What heat treatment processes can be performed using tubular furnaces? Unlock Precision for Materials Science

- What protective role does a wet hydrogen (Ar/H2) environment play in a tube furnace for thin film stability testing?

- What is the role of a tubular furnace in the conversion of coffee ground powder into biochar? Master Precise Pyrolysis

- What is a tube furnace and what are its primary uses? Essential for Controlled High-Temperature Processes

- What is the purpose of introducing high-purity nitrogen into a tube furnace? Enhance Biomass Torrefaction Efficiency

- What are the advantages of using a tube furnace with nitrogen control for nanoporous carbon? Enhance Your Lab Results

- What is a vertical tube furnace and how does it function? Optimize Material Processing with Precision

- How can tube furnaces be enhanced with multiple heating zones and what benefits does this provide? Unlock Precise Temperature Control