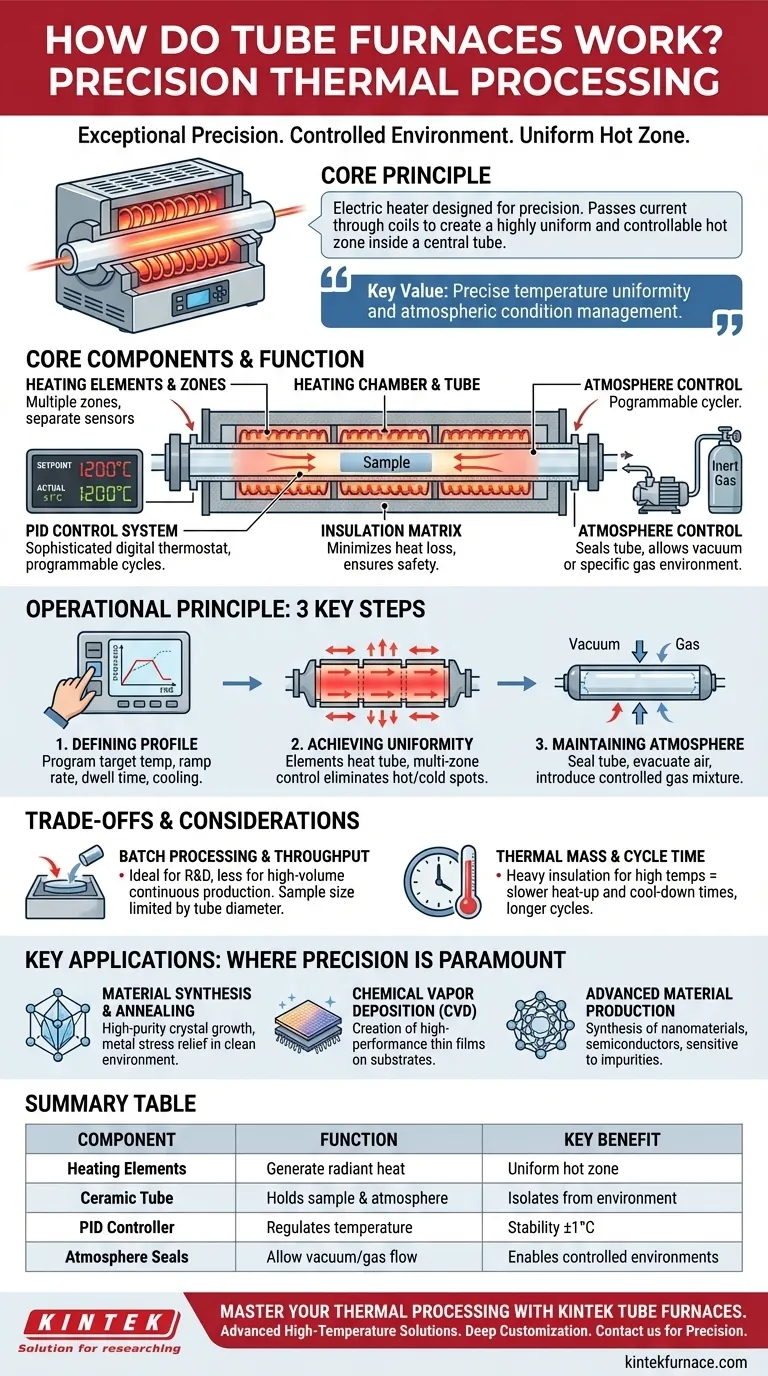

At its core, a tube furnace is an electric heater designed for exceptional precision. It works by passing an electrical current through heating coils that surround a central, cylindrical tube. This design creates a highly uniform and controllable hot zone inside the tube, which can be sealed to maintain a specific atmosphere for processing materials.

A tube furnace's primary function is not just heating, but providing an extremely controlled thermal environment. Its value lies in the ability to precisely manage temperature uniformity and atmospheric conditions, which is impossible with a standard oven.

The Core Components of a Tube Furnace

To understand its operation, we must first look at its key components. Each part plays a critical role in achieving high-precision thermal processing.

The Heating Chamber and Tube

The sample is placed inside a central tube, typically made of quartz, alumina, or another ceramic. This tube contains the sample and the desired atmosphere, isolating it from the heating elements and the outside environment.

The Heating Elements

The tube is surrounded by electric heating coils or elements. When electricity flows through them, they generate radiant heat. In more advanced furnaces, these elements are divided into multiple "zones," each with its own sensor, allowing for exceptionally uniform temperature along the length of the tube.

The Insulation Matrix

The heating elements are embedded within a high-quality thermal insulation matrix. This material minimizes heat loss, improves energy efficiency, and ensures the outer casing of the furnace remains cool and safe to the touch.

The Control System

Modern tube furnaces use a PID (Proportional-Integral-Derivative) controller. This is a sophisticated digital thermostat that continuously monitors the temperature and adjusts the power sent to the heating elements to hold the setpoint with extreme accuracy, often within ±1°C. These controllers are programmable, allowing for complex heating and cooling cycles.

Atmosphere Control Components

Flanges or end caps are used to seal the ends of the tube. These caps have ports that allow for the attachment of a vacuum pump to remove air or a gas system to introduce a controlled atmosphere, such as an inert gas like argon.

The Operational Principle: From Power to Precision

The components work in concert to create a tightly controlled processing environment. The process generally follows three key steps.

1. Defining the Thermal Profile

The user programs the desired thermal process into the control panel. This includes the target temperature, the rate of heating (ramp rate), how long to hold the temperature (dwell time), and the cooling profile. The furnace can store multiple programs for repeatable experiments.

2. Achieving Uniform Temperature

As power is supplied, the heating elements heat the tube. The cylindrical geometry naturally promotes even heat distribution. For multi-zone furnaces, the controller independently manages each section to eliminate hot or cold spots, creating a perfectly uniform thermal zone.

3. Maintaining a Controlled Atmosphere

For processes sensitive to oxygen or other contaminants, the tube is sealed. A vacuum pump may be used to evacuate the chamber to pressures as low as 10⁻⁵ torr. Afterward, a specific gas or gas mixture can be flowed into the tube at a controlled rate to create the ideal chemical environment.

Understanding the Trade-offs

While powerful, tube furnaces have specific characteristics that make them ideal for some tasks but less suitable for others.

Batch vs. Continuous Processing

A tube furnace is fundamentally a batch processing tool. Samples are loaded, processed, and then unloaded. This is perfect for research and development but can be a bottleneck for high-volume industrial production, where continuous conveyor-style furnaces may be better.

Size and Throughput Limitations

The diameter of the tube inherently limits the physical size of the sample. While furnaces can be scaled up, they are generally not designed for processing very large or bulky components.

Thermal Mass and Cycle Time

The heavy insulation required to reach high temperatures (up to 1800°C) and maintain stability means the furnace has a high thermal mass. This results in slower heat-up and cool-down times compared to other heating methods, which can lengthen the total cycle time per batch.

Key Applications Where Precision Is Paramount

The unique capabilities of a tube furnace make it indispensable in several advanced fields where material properties are defined by their processing conditions.

Material Synthesis and Annealing

Creating high-purity crystals or annealing metals to relieve internal stresses requires slow, uniform heating and cooling in a clean environment. A tube furnace provides exactly this level of control.

Chemical Vapor Deposition (CVD)

CVD is a process used to create high-performance thin films, such as those on semiconductor wafers. It requires a precursor gas to react at a specific temperature and deposit on a substrate. The precise temperature and atmosphere control of a tube furnace is essential for this.

Advanced Material Production

The synthesis of nanomaterials, semiconductors, and other advanced materials is highly sensitive to impurities and temperature fluctuations. The sealed, controlled environment of a tube furnace is critical for producing materials with consistent and predictable properties.

Is a Tube Furnace Right for Your Application?

Choosing the right thermal processing tool depends entirely on your goal.

- If your primary focus is high-purity synthesis or processing in a non-oxygen environment: The atmosphere control of a sealed tube furnace is non-negotiable.

- If your primary focus is achieving the most uniform temperature possible across a sample: The design of a multi-zone tube furnace is superior to almost any other oven type.

- If your primary focus is exploratory research or developing new thermal processes: The versatility, programmability, and compact bench-top size of a tube furnace make it an ideal lab instrument.

Ultimately, a tube furnace empowers you to masterfully control the conditions under which materials are transformed.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Heating Elements | Generate radiant heat around the tube | Creates a uniform hot zone |

| Ceramic Tube | Holds the sample and process atmosphere | Isolates the sample from the environment |

| PID Controller | Precisely regulates temperature | Maintains stability within ±1°C |

| Atmosphere Seals | Allow vacuum or gas flow into the tube | Enables oxygen-free or reactive environments |

Ready to Master Your Thermal Processing?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Muffle, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Contact us today to discuss how our tube furnaces can bring precision, uniformity, and control to your material synthesis, annealing, or CVD processes.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency