In short, tube furnaces are used for a wide range of precise thermal processes where both temperature and atmospheric conditions must be strictly controlled. Their primary applications include material synthesis, annealing, purification, coating, and heat treatment for advanced research and specialized industrial production.

The core value of a tube furnace is not just its ability to get hot, but its capacity to create a highly uniform and isolated thermal environment. This makes it the definitive tool for any process where sample contamination from air or inconsistent heating would compromise the result.

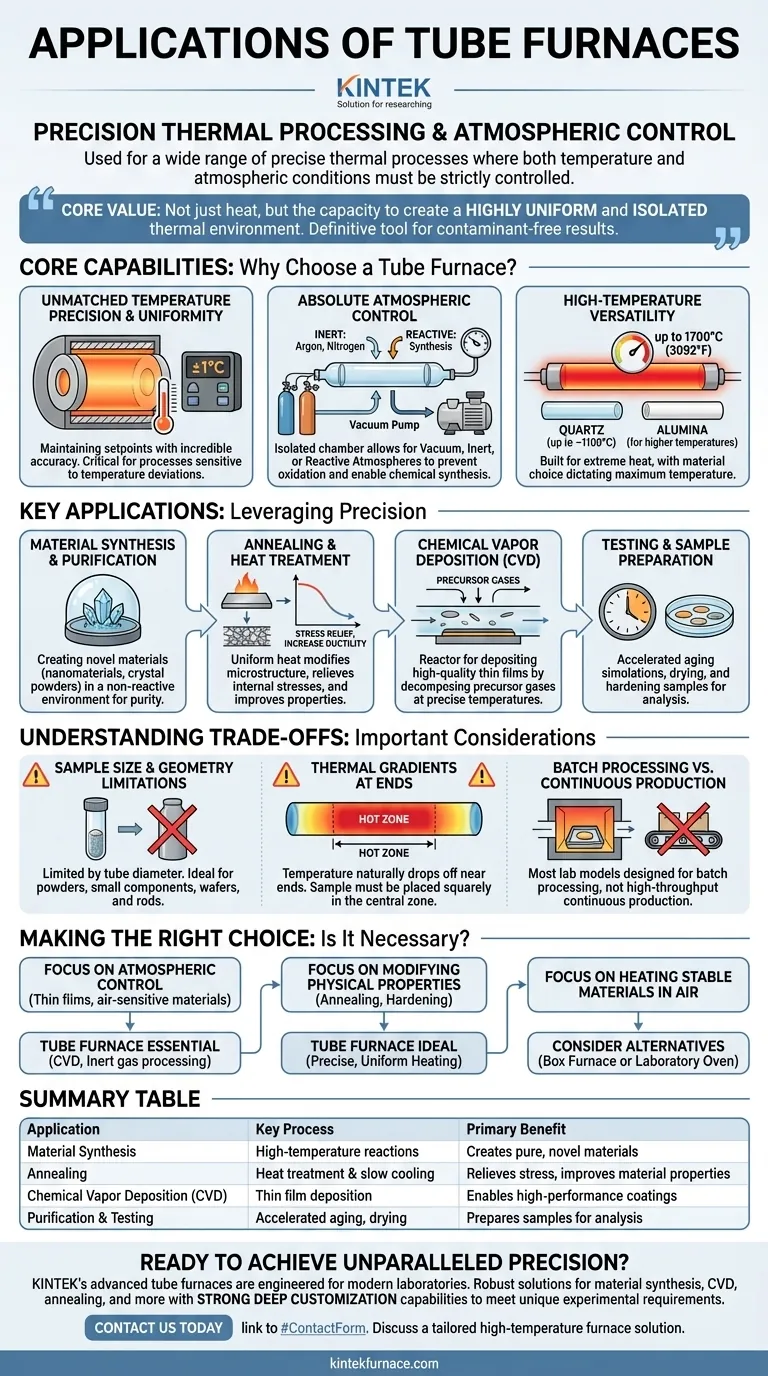

The Core Capabilities of a Tube Furnace

To understand its applications, you must first understand its fundamental design advantages. A tube furnace is chosen over other heating equipment when specific environmental conditions are non-negotiable.

Unmatched Temperature Precision and Uniformity

A tube furnace's cylindrical heating chamber is designed to provide exceptional temperature uniformity across its central zone.

Modern controllers can maintain a setpoint with incredible accuracy, often within ±1°C. This precision is critical for processes where slight temperature deviations can drastically alter material properties.

Absolute Atmospheric Control

The defining feature of a tube furnace is the tube itself, which acts as an isolated chamber.

By sealing the ends of the tube (typically made of quartz or alumina), you can evacuate the air to create a vacuum or introduce a specific gas. This allows for processing in an inert atmosphere (like argon or nitrogen) to prevent oxidation or a reactive atmosphere for chemical synthesis.

High-Temperature Versatility

Tube furnaces are built to reach very high temperatures, often exceeding 1700°C (3092°F).

The choice of tube material dictates the maximum operating temperature. Quartz tubes are common for processes up to ~1100°C, while alumina tubes are required for higher temperatures, offering versatility for a vast range of materials.

Key Applications in Research and Industry

These core capabilities directly enable the furnace's most common applications. Each use case leverages the furnace's precision to achieve a specific material outcome.

Material Synthesis and Purification

Creating novel materials, from nanomaterials to crystal powders, often requires high temperatures and a non-reactive environment. The furnace's controlled atmosphere prevents unwanted chemical reactions, ensuring the purity of the final product.

Annealing and Heat Treatment

Annealing involves heating a material and holding it at a specific temperature before cooling it slowly. In a tube furnace, this process modifies a material's microstructure to relieve internal stresses, increase ductility, and improve its overall properties. The uniform heat is essential for treating the entire sample evenly.

Chemical Vapor Deposition (CVD)

CVD is a process used to deposit high-quality, high-performance thin films onto a substrate. The tube furnace acts as a reactor where precursor gases are introduced, reacting and decomposing on the substrate surface at a precise temperature to form the desired coating. This would be impossible without absolute atmospheric and thermal control.

Testing and Sample Preparation

Tube furnaces are also used for process testing and sample preparation. Applications like accelerated aging expose materials to high temperatures to simulate long-term use, while drying and hardening processes use controlled heat to prepare samples for further analysis or use.

Understanding the Trade-offs

While powerful, a tube furnace is not the right tool for every job. Understanding its limitations is key to using it effectively.

Sample Size and Geometry Limitations

The primary constraint is the tube's diameter. Tube furnaces are ideal for processing powders, small components, wafers, or rods, but they cannot accommodate large or irregularly shaped objects. For those, a box or chamber furnace is more appropriate.

Thermal Gradients at the Ends

While the central zone of the furnace is highly uniform, the temperature naturally drops off near the ends of the tube. This is a known characteristic that must be accounted for by ensuring the sample is placed squarely in the central "hot zone" for consistent results.

Batch Processing vs. Continuous Production

Most laboratory-scale tube furnaces are designed for batch processing, where one sample or a group of samples is processed at a time. While larger, specialized industrial versions are capable of continuous production, the standard lab model is not suited for high-throughput assembly lines.

Making the Right Choice for Your Process

Your specific goal determines whether a tube furnace is the necessary tool.

- If your primary focus is creating thin films or synthesizing air-sensitive materials: A tube furnace is essential for its atmospheric control capabilities (CVD, inert gas processing).

- If your primary focus is modifying the physical properties of a material: The precise and uniform heating of a tube furnace makes it ideal for annealing, hardening, and tempering.

- If your primary focus is simply heating a stable material in air: A tube furnace may be overkill; a more economical box furnace or laboratory oven could be a better fit.

Ultimately, a tube furnace is the indispensable instrument for any thermal process that demands absolute precision and control over the sample's environment.

Summary Table:

| Application | Key Process | Primary Benefit |

|---|---|---|

| Material Synthesis | High-temperature reactions | Creates pure, novel materials |

| Annealing | Heat treatment & slow cooling | Relieves stress, improves material properties |

| Chemical Vapor Deposition (CVD) | Thin film deposition | Enables high-performance coatings |

| Purification & Testing | Accelerated aging, drying | Prepares samples for analysis |

Ready to achieve unparalleled precision in your thermal processes?

KINTEK's advanced tube furnaces are engineered to meet the rigorous demands of modern laboratories. Leveraging our exceptional R&D and in-house manufacturing, we provide robust solutions for material synthesis, CVD, annealing, and more. Our product line, including Tube Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Contact us today to discuss how we can tailor a high-temperature furnace solution for your specific application. Get in touch via our Contact Form

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab