At its core, a tubular furnace is a high-temperature heating device used for a wide range of thermal processes where precision and atmospheric control are critical. Its primary function is to subject small samples to controlled heat treatment in a contained environment, making it indispensable for applications like materials research, chemical synthesis, and small-batch production.

The true value of a tubular furnace isn't just its ability to get hot, but its capacity to create a highly uniform and atmospherically-controlled thermal environment. This precision is why it is the go-to instrument for processing sensitive and advanced materials.

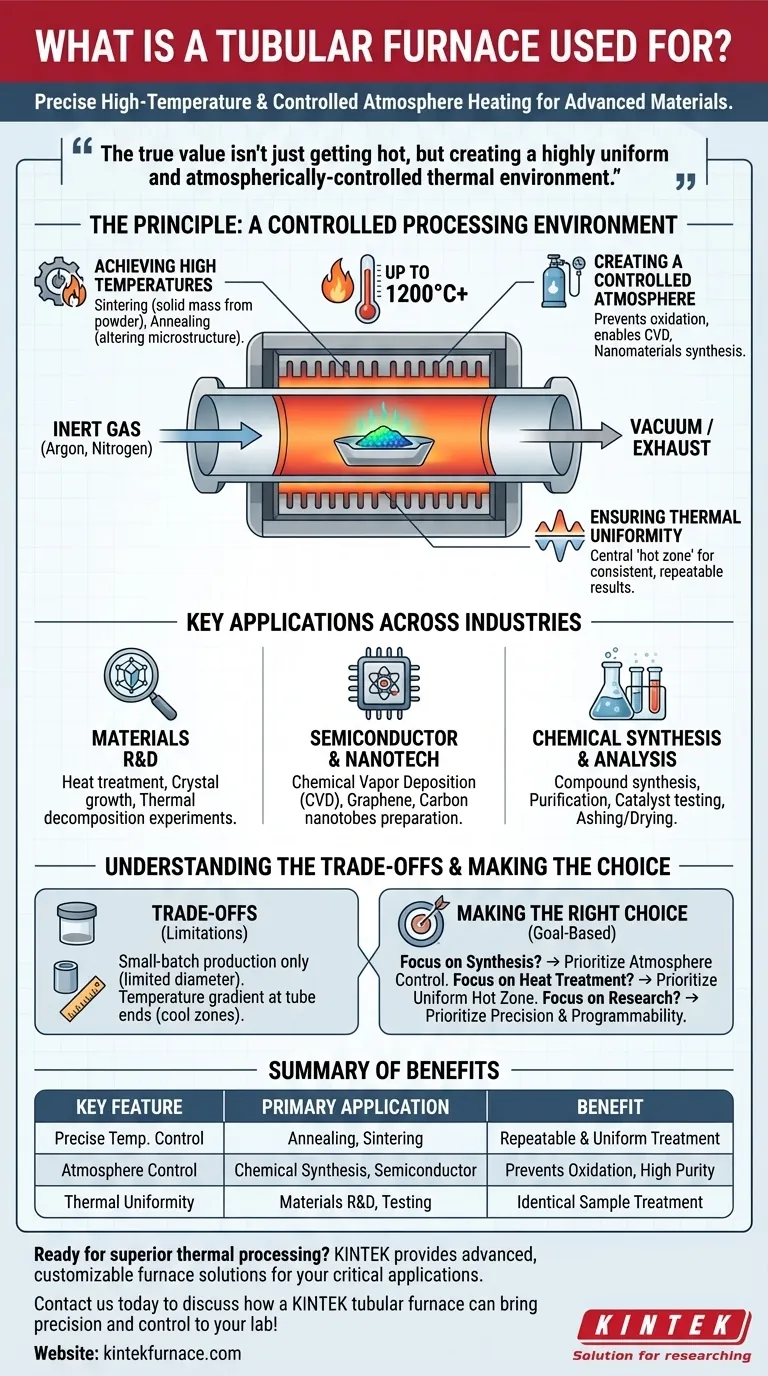

The Principle: A Controlled Processing Environment

A tubular furnace operates on a simple but powerful principle. It uses heating elements to surround a ceramic or metallic tube, creating a zone of uniform temperature. Material placed inside this tube can be heated, held at a specific temperature, and cooled according to a precise program.

Achieving High Temperatures with Precision

The primary purpose is to generate heat, often up to 1200°C or even higher, depending on the model. This is essential for processes like sintering, where powdered material is heated to create a solid mass, or annealing, which alters a material's microstructure to make it more ductile.

Creating a Controlled Atmosphere

The enclosed tube allows for complete control over the gaseous environment surrounding the sample. This is critical for preventing oxidation or unwanted chemical reactions. An inert gas (like argon or nitrogen) can be purged through the tube, or the process can be run under a vacuum.

This capability is vital for synthesizing materials like carbon nanotubes, processing sensitive semiconductors, or conducting purification processes that would fail in the presence of air.

Ensuring Thermal Uniformity

High-quality tubular furnaces are designed to have a central "hot zone" where the temperature is extremely stable and uniform. This ensures that the entire sample receives the exact same thermal treatment, which is crucial for achieving repeatable results in both research and production.

Key Applications Across Industries

The combination of precise temperature, atmosphere control, and uniformity makes the tubular furnace a versatile tool in many advanced fields.

Materials Research and Development

This is the furnace's home turf. Researchers use it for creating and testing new materials. Common applications include heat treatment of metals and ceramics, crystal growth, and running thermal decomposition experiments to study material stability.

Semiconductor and Nanotechnology Manufacturing

In this field, purity is everything. Tubular furnaces are used for Chemical Vapor Deposition (CVD), a process where a thin film is deposited onto a substrate from a vapor. They are also essential for preparing nanomaterials like graphene and carbon nanotubes, which require high temperatures and strictly controlled atmospheres.

Chemical Synthesis and Analysis

Chemists use tubular furnaces for synthesizing both organic and inorganic compounds, purification, and catalyst testing. The furnace provides the controlled energy input needed to drive specific chemical reactions. It is also used for sample preparation, such as ashing or drying, before chemical analysis.

Understanding the Trade-offs

While powerful, tubular furnaces are not a universal solution. Understanding their limitations is key to using them effectively.

Sample Size and Throughput

By design, tubular furnaces are intended for experimental and small-batch production. The diameter of the tube inherently limits the size and volume of the material that can be processed at one time, making them unsuitable for mass production.

Vertical vs. Horizontal Configurations

Most tubular furnaces are horizontal, which is ideal for batch processing. However, vertical tube furnaces exist for specific applications like gas quenching tests or processes where it's beneficial for material to drop out of the hot zone after processing.

Temperature Gradient at the Ends

The most uniform temperature is found in the center of the tube. The ends of the tube will always be cooler than the central hot zone. For processes requiring the highest uniformity, it is critical to place the sample squarely in the center and to understand the specified length of the furnace's uniform hot zone.

Making the Right Choice for Your Process

To determine if a tubular furnace is the right tool, consider your ultimate goal.

- If your primary focus is materials synthesis or semiconductor processing: The ability to control the atmosphere to prevent oxidation and contamination is your most critical feature.

- If your primary focus is heat treatment (annealing, sintering): Prioritize a furnace with a long, verified uniform hot zone to ensure your entire part is treated evenly.

- If your primary focus is fundamental research or sample testing: The furnace's programmability and precision temperature control are essential for repeatable experiments.

Ultimately, a tubular furnace is selected when the integrity and properties of your material depend on an exceptionally controlled thermal environment.

Summary Table:

| Key Feature | Primary Application | Benefit |

|---|---|---|

| Precise Temperature Control | Annealing, Sintering | Ensures repeatable and uniform heat treatment. |

| Atmosphere Control (Inert Gas/Vacuum) | Chemical Synthesis, Semiconductor Processing | Prevents oxidation and contamination for pure results. |

| Thermal Uniformity (Hot Zone) | Materials R&D, Sample Testing | Guarantees the entire sample receives identical treatment. |

Ready to achieve superior thermal processing for your lab?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements for materials research, chemical synthesis, or semiconductor processing.

Contact us today to discuss how a KINTEK tubular furnace can bring precision and control to your most critical applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab