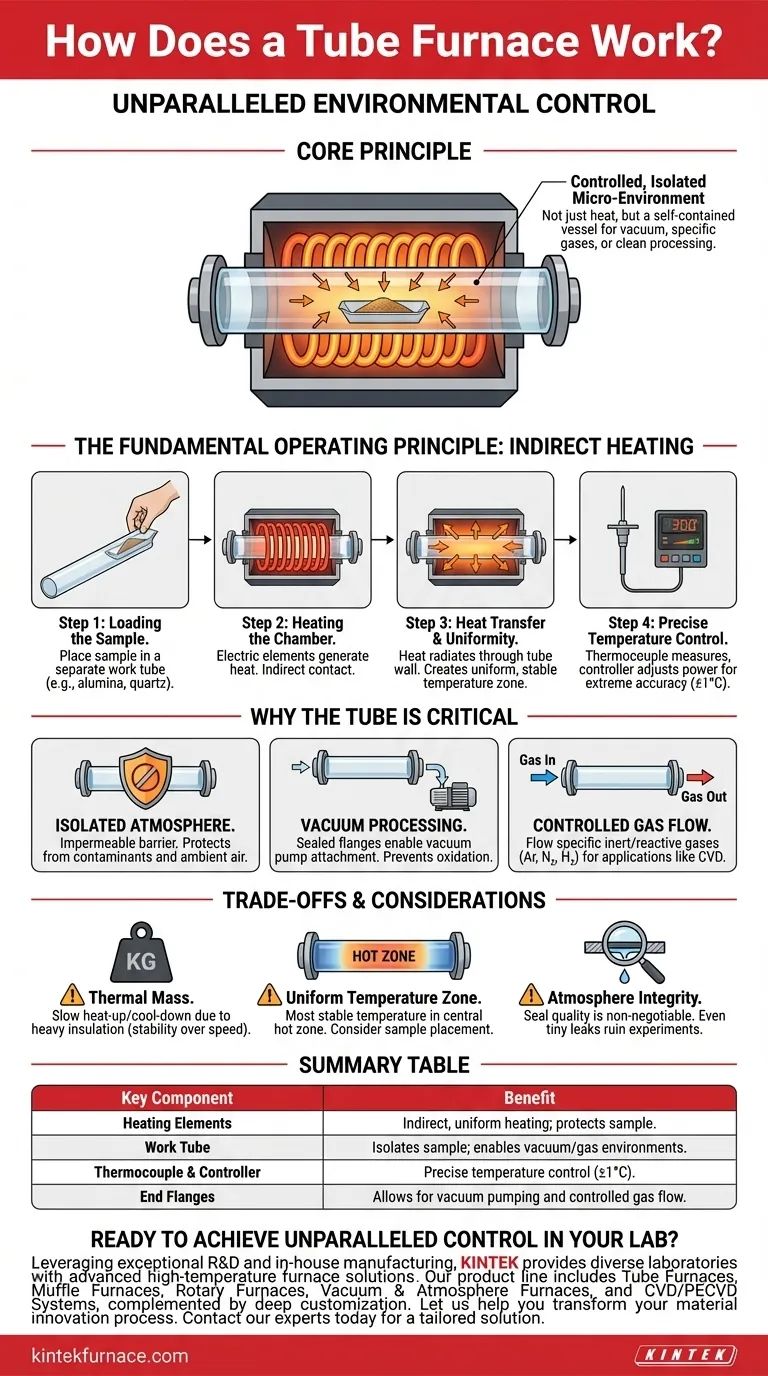

At its core, a tube furnace is a high-temperature oven designed for unparalleled environmental control. It works by placing a sample inside a sealed cylindrical tube, which is then heated externally by surrounding electrical heating elements. This indirect heating method is the furnace's defining feature, as it isolates the sample from the heating source and the outside air, allowing for precise control over both temperature and the internal atmosphere.

The crucial insight is that a tube furnace's primary value comes from its ability to create a controlled, isolated micro-environment. While it provides heat, its real power lies in using the central tube as a self-contained vessel for processing materials in a vacuum, with specific gases, or simply free from airborne contaminants.

The Fundamental Operating Principle: Indirect Heating

A tube furnace's operation is elegant in its simplicity. The process is designed to separate the heat source from the material being processed, which is the key to its precision.

Step 1: Loading the Sample

The process begins by placing the sample or substrate material inside a separate, often long and narrow, work tube. This tube is typically made of a ceramic like alumina or a high-purity glass like quartz, chosen for its thermal and chemical resistance.

Step 2: Heating the Chamber

Once the work tube is positioned in the furnace's central cavity, the furnace is activated. Electric heating elements, usually coils wrapped around the chamber, generate heat through electrical resistance. These elements heat the chamber's interior but never make direct contact with the sample.

Step 3: Heat Transfer and Uniformity

Heat radiates from the elements and is transferred through the wall of the work tube to the sample inside. The cylindrical geometry of the furnace ensures that heat is applied evenly from all sides, creating a highly uniform and stable temperature zone in the center of the tube.

Step 4: Precise Temperature Control

A thermocouple measures the temperature, feeding data back to a digital controller. This controller adjusts the power to the heating elements to maintain the desired temperature setpoint with extreme accuracy, often within a single degree. After the process is complete, the furnace cools down before the sample is safely removed.

Why the Tube is the Critical Component

The work tube is far more than a simple container; it is the heart of the furnace's functionality. It transforms the device from a simple oven into a sophisticated processing tool.

Creating an Isolated Atmosphere

The tube acts as an impermeable barrier. It protects the sample from any impurities given off by the heating elements and, more importantly, isolates it from the ambient air outside the furnace.

Enabling Vacuum Processing

By fitting the ends of the tube with sealed flanges, a vacuum pump can be attached to evacuate the air. This creates a vacuum environment, which is essential for preventing oxidation and other unwanted reactions when working with sensitive materials.

Facilitating Controlled Gas Flow

The same end flanges can be equipped with gas inlet and outlet ports. This allows a user to flow specific inert or reactive gases (like argon, nitrogen, or hydrogen) through the tube during heating. This capability is fundamental for advanced applications like Chemical Vapor Deposition (CVD), where reactive gases deposit a thin film onto a substrate.

Understanding the Trade-offs and Considerations

While powerful, tube furnaces have characteristics that users must understand to achieve successful results.

Thermal Mass and Ramp Rates

The heavy insulation required for high-temperature stability gives tube furnaces significant thermal mass. This means they heat up and cool down relatively slowly. This trade-off of speed for stability is a core design feature.

The "Uniform Temperature Zone"

Perfect temperature uniformity is not possible across the entire length of the tube. The most stable and uniform temperature is found in a specific "hot zone" in the center. The ends of the tube will always be slightly cooler, a critical factor to consider when positioning your sample.

Atmosphere Integrity is Paramount

For vacuum or controlled-gas applications, the quality of the system's seals is non-negotiable. Even a minuscule leak in a flange gasket can compromise the internal atmosphere and ruin an experiment by introducing oxygen or moisture.

Making the Right Choice for Your Goal

Understanding the operating principle allows you to leverage the furnace for your specific application.

- If your primary focus is annealing or purification: Your goal is a stable temperature in an inert atmosphere or vacuum, so confirming the integrity of your tube seals is your most critical step.

- If your primary focus is material synthesis: You need a highly repeatable temperature profile, so ensuring your sample is placed in the center of the uniform hot zone is essential for consistent results.

- If your primary focus is Chemical Vapor Deposition (CVD): You must treat the furnace as a chemical reactor, where precise control over gas flow rates, pressure, and temperature profile work together to create the final product.

By mastering the interplay between heat and the isolated atmosphere within the tube, you can transform a tube furnace from a simple heat source into a precise instrument for material innovation.

Summary Table:

| Key Component | Function | Benefit |

|---|---|---|

| Heating Elements | Heat the chamber externally | Indirect, uniform heating; protects sample |

| Work Tube | Holds the sample; creates a sealed barrier | Isolates sample; enables vacuum/gas environments |

| Thermocouple & Controller | Measure and regulate temperature | Precise temperature control (±1°C) |

| End Flanges | Seal the tube ends with ports | Allows for vacuum pumping and controlled gas flow |

Ready to Achieve Unparalleled Control in Your Lab?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Let us help you transform your material innovation process. Contact our experts today to discuss your specific application and receive a tailored solution.

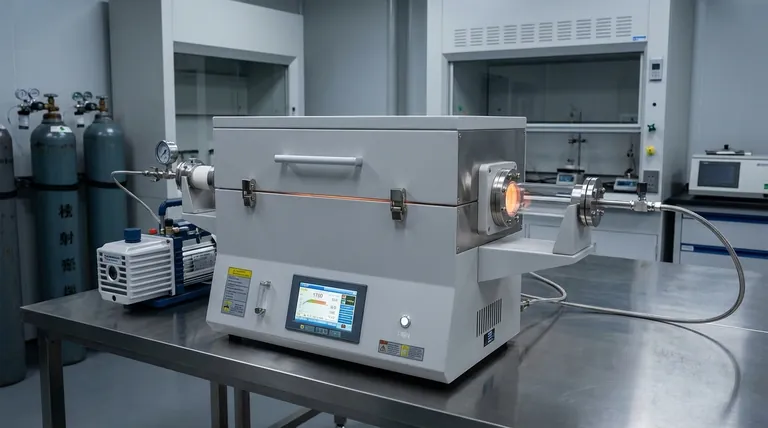

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability