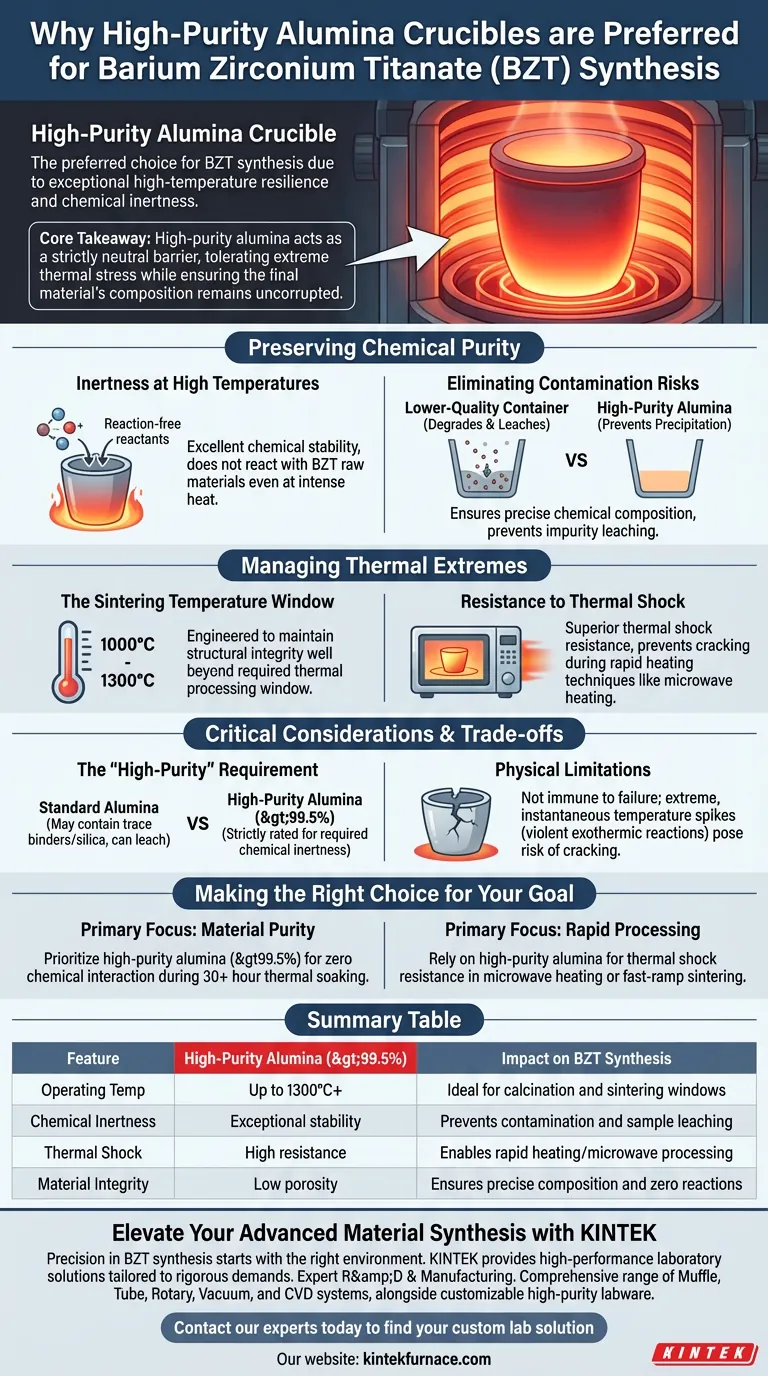

High-purity alumina crucibles are the preferred choice for Barium Zirconium Titanate (BZT) synthesis due to their exceptional combination of high-temperature resilience and chemical inertness. They withstand critical processing temperatures between 1000°C and 1300°C without reacting with the BZT reactants, thereby preventing contamination and ensuring the structural integrity of the vessel during rapid heating methods.

Core Takeaway The success of BZT synthesis depends on isolating the chemical reaction from the synthesis environment. High-purity alumina acts as a strictly neutral barrier, tolerating extreme thermal stress while ensuring the final material’s composition remains uncorrupted by the container itself.

Preserving Chemical Purity

Inertness at High Temperatures

The primary challenge in BZT synthesis is preventing the container from becoming part of the chemical reaction.

High-purity alumina possesses excellent chemical stability, meaning it does not react with BZT raw materials even when subjected to intense heat.

Eliminating Contamination Risks

During the calcination and sintering phases, lower-quality containers can degrade, causing elements to precipitate from the container walls into the sample.

High-purity alumina prevents this precipitation of impurities. This ensures that the chemical composition of the BZT remains precise and that the experimental results reflect the properties of the sample, not the crucible.

Managing Thermal Extremes

The Sintering Temperature Window

BZT synthesis requires a thermal processing window typically between 1000°C and 1300°C.

Alumina crucibles are engineered to maintain structural integrity well beyond these temperatures. This allows for prolonged thermal soaking without the risk of the vessel softening or deforming.

Resistance to Thermal Shock

Modern synthesis methods often employ rapid heating techniques, such as microwave heating.

These methods generate heat quickly, creating significant thermal stress. High-purity alumina offers superior thermal shock resistance, preventing the crucible from cracking or shattering under the strain of rapid temperature changes.

Critical Considerations and Trade-offs

The "High-Purity" Requirement

It is critical to distinguish between standard alumina and high-purity alumina.

Standard alumina may contain trace binders or silica that can leach out at 1300°C. To achieve the results described above, the crucible must be strictly rated as high-purity to guarantee the chemical inertness required for sensitive BZT synthesis.

Physical Limitations

While alumina is highly resistant to thermal shock compared to many ceramics, it is not immune to failure.

Extreme, instantaneous temperature spikes (such as those in violent exothermic reactions) still pose a risk of cracking. Users must ensure their heating ramp rates stay within the material's specific thermal shock limits.

Making the Right Choice for Your Goal

When selecting labware for BZT synthesis, your choice depends on your specific experimental parameters.

- If your primary focus is Material Purity: Prioritize high-purity alumina (>99.5%) to ensure zero chemical interaction or leaching during the 30+ hour thermal soaking periods.

- If your primary focus is Rapid Processing: Rely on high-purity alumina for its ability to withstand the thermal shock inherent in microwave heating or fast-ramp sintering cycles.

Select high-purity alumina not just as a container, but as a critical component in maintaining the validity of your chemical synthesis.

Summary Table:

| Feature | High-Purity Alumina (>99.5%) | Impact on BZT Synthesis |

|---|---|---|

| Operating Temp | Up to 1300°C+ | Ideal for calcination and sintering windows |

| Chemical Inertness | Exceptional stability | Prevents contamination and sample leaching |

| Thermal Shock | High resistance | Enables rapid heating/microwave processing |

| Material Integrity | Low porosity | Ensures precise composition and zero reactions |

Elevate Your Advanced Material Synthesis with KINTEK

Precision in BZT synthesis starts with the right environment. KINTEK provides high-performance laboratory solutions tailored to the rigorous demands of material science. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside high-purity labware that is fully customizable for your unique experimental needs.

Don’t compromise on purity or thermal control. Partner with KINTEK to ensure your high-temperature processes yield consistent, high-quality results.

Contact our experts today to find your custom lab solution

Visual Guide

References

- T. Avanish Babu, W. Madhuri. Energy storage and catalytic behaviour of cmWave assisted BZT and flexible electrospun BZT fibers for energy harvesting applications. DOI: 10.1038/s41598-024-52705-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the main composition percentages of alumina tubes? Optimize Performance for High-Temperature Applications

- Why are high-purity alumina grinding balls used for Al2O3/TiC milling? Master Chemical Consistency

- How are laboratory furnaces used in material synthesis? Unlock Precise Control for Advanced Materials

- What is the importance of using external thermometers for lead bath monitoring? Ensure Precision in Chemical Refining

- How does a high-precision analog pressure gauge contribute to the gas delivery system in magnesium combustion experiments?

- What is the function of high-precision molds and laboratory presses in LLTO preparation? Ensure Material Consistency

- What is the function of PTFE sealing rings in plastic pyrolysis? Ensure Safe, Anaerobic Material Decomposition

- Why are high-purity alumina crucibles used for phosphor synthesis? Ensure Maximum Luminescence and Spectral Purity