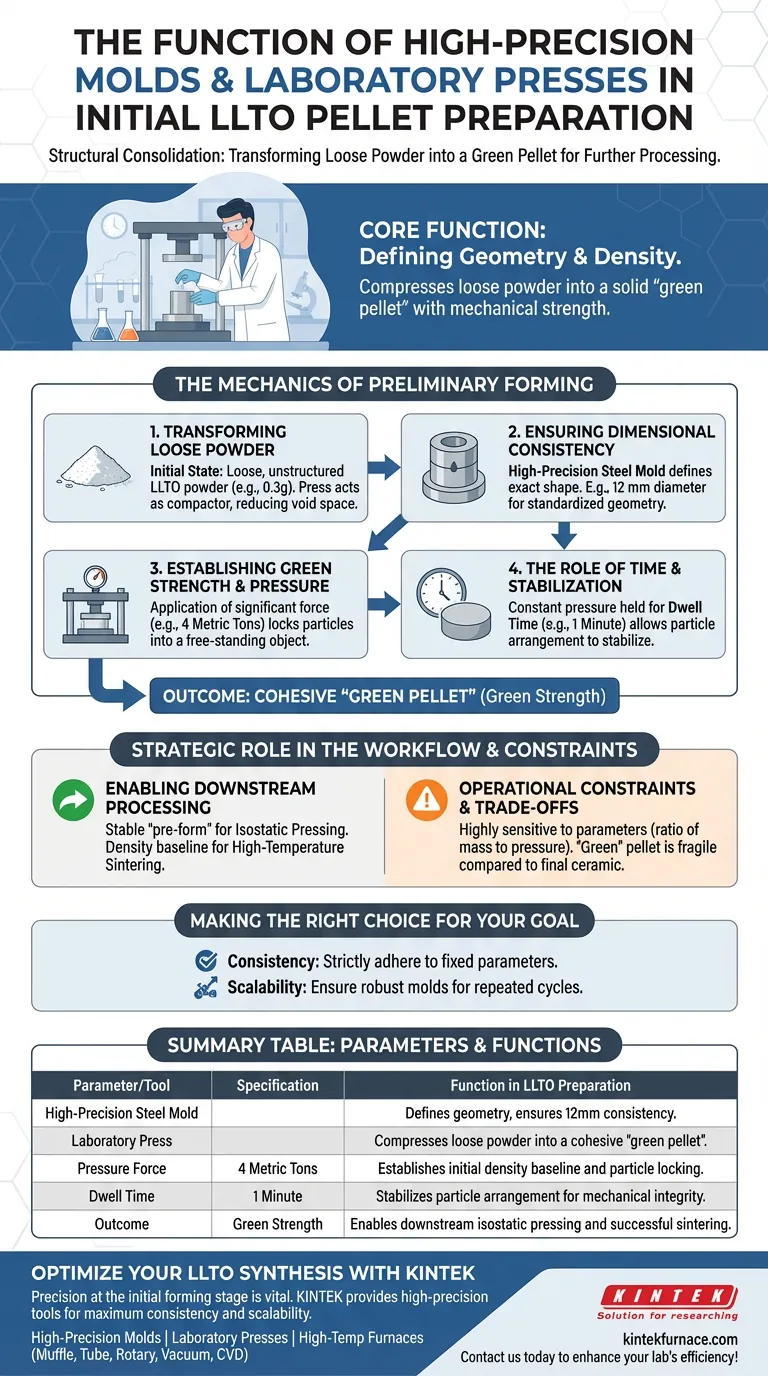

High-precision steel molds and laboratory presses serve the critical function of structural consolidation. In the initial preparation of Lithium Lanthanum Titanate (LLTO), these tools define the geometry and density of the material by compressing loose powder into a solid form. This step transforms volatile powder into a "green pellet" with sufficient mechanical strength to serve as a foundation for further processing.

The primary objective is to convert loose, difficult-to-handle powder into a cohesive, geometric unit. By applying specific, constant pressure, this equipment establishes the initial structural integrity required for subsequent isostatic pressing and high-temperature sintering.

The Mechanics of Preliminary Forming

Transforming Loose Powder into Solids

The initial state of LLTO is a loose powder which lacks structure. The laboratory press functions as a compactor, forcing the discrete particles together to reduce void space.

Ensuring Dimensional Consistency

High-precision steel molds are used to define the exact shape and size of the pellet. For example, a 12 mm diameter mold is often used to ensure the standardized geometry required for consistent experimental results.

Establishing Green Strength

The application of force creates "green strength"—the mechanical integrity of an unsintered ceramic. By subjecting a specific amount of powder (e.g., 0.3 grams) to significant force, the particles lock together to form a free-standing object.

The Role of Time and Pressure

The function of the press is not just to squeeze, but to hold constant pressure. A typical protocol involves applying 4 metric tons of pressure and maintaining it for 1 minute to allow the particle arrangement to stabilize.

Strategic Role in the Workflow

Enabling Downstream Processing

The green pellet is not the final product; it is a prerequisite. The initial pressing provides a stable "pre-form" that allows the material to undergo isostatic pressing without crumbling.

Preparation for Sintering

High-temperature sintering requires a compacted base to be effective. The laboratory press creates the necessary density baseline that allows the ceramic to densify properly during the heating phase.

Operational Constraints and Trade-offs

Dependence on Specific Parameters

The success of this function is highly sensitive to the inputs. Deviating from the established ratio of mass (0.3 g) to pressure (4 metric tons) can result in pellets that are too brittle to handle or too dense to sinter evenly.

The "Green" Limitation

While the press creates mechanical strength, the resulting pellet remains fragile compared to the final ceramic. It provides enough strength for handling and the next process step, but it lacks the chemical bonding of the final sintered product.

Making the Right Choice for Your Goal

To maximize the effectiveness of your preparation stage, consider your specific objective:

- If your primary focus is Consistency: Adhere strictly to the fixed parameters (e.g., 4 metric tons for 1 minute) to ensure every pellet has an identical density profile.

- If your primary focus is Scalability: Ensure your high-precision molds are robust enough to maintain the 12 mm diameter tolerance over repeated high-pressure cycles.

Precision at this initial stage is the single most important factor in securing a stable foundation for the final ceramic electrolyte.

Summary Table:

| Parameter | Specification | Function in LLTO Preparation |

|---|---|---|

| Tooling | High-Precision Steel Mold | Defines geometry and ensures 12mm dimensional consistency. |

| Equipment | Laboratory Press | Compresses loose powder into a cohesive 'green pellet'. |

| Pressure Force | 4 Metric Tons | Establishes the initial density baseline and particle locking. |

| Dwell Time | 1 Minute | Stabilizes particle arrangement for mechanical integrity. |

| Outcome | Green Strength | Enables downstream isostatic pressing and successful sintering. |

Optimize Your LLTO Material Synthesis with KINTEK

Precision at the initial forming stage is vital for high-performance ceramic electrolytes. KINTEK provides the high-precision tools necessary to ensure your research achieves maximum consistency and scalability.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of laboratory equipment including:

- High-Precision Molds: Specifically designed for repeatable ceramic pellet geometry.

- Laboratory Presses: Delivering constant pressure for superior green strength.

- High-Temp Furnaces: Muffle, Tube, Rotary, Vacuum, and CVD systems for expert sintering.

All our systems are customizable to meet your unique laboratory needs. Contact us today to enhance your lab's efficiency and material integrity!

Visual Guide

References

- Pei‐Yin Chen, Sheng‐Heng Chung. A solid-state electrolyte for electrochemical lithium–sulfur cells. DOI: 10.1039/d3ra05937e

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the advantage of the circulating water multifunctional vacuum pump being one machine for multiple purposes? Streamline Lab Work Efficiently

- What role do ceramic crucibles play in the initial stages of coating? Ensure High-Purity Metal Melts Today

- Why is a high-purity quartz boat selected for Tellurium purification? Achieve 5N+ Semiconductor Grade Results

- What are the benefits of a vacuum chamber? Achieve Unmatched Process Control and Purity

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What mechanical properties should be evaluated for alumina ceramic furnace tubes? Ensure Durability and Performance

- What is the purpose of using a PID controller to drive a heating furnace? Master Thermal Kinetics Precision

- What is the primary function of high-purity graphite crucibles? Ensure Superior Purity in Aluminum Alloy Melting