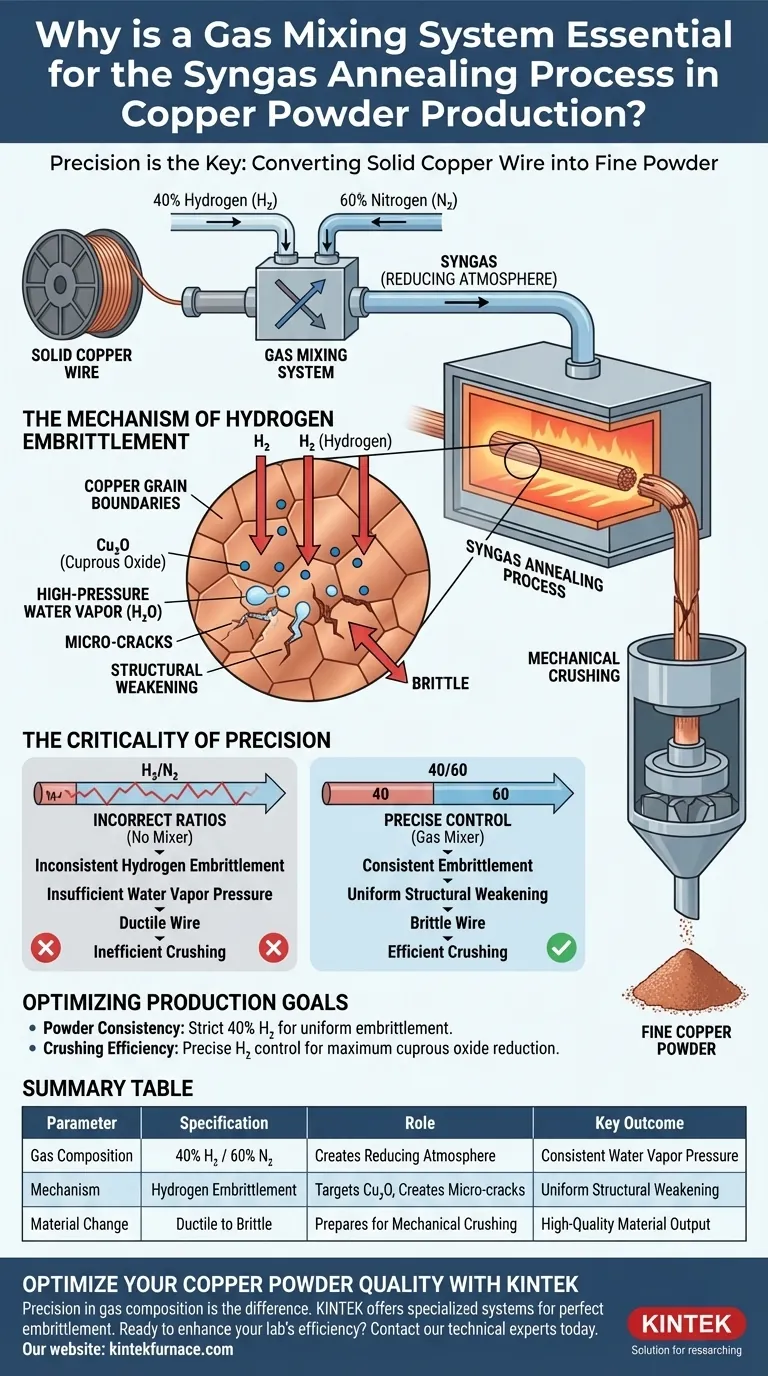

Precision is the key to converting solid copper wire into powder. A gas mixing system is essential for the syngas annealing process because it blends specific ratios of gases—typically 40% hydrogen and 60% nitrogen—to create a strictly controlled reducing atmosphere. This precise environment is required to induce hydrogen embrittlement, a chemical change that structurally weakens the wire to prepare it for mechanical crushing.

The gas mixing system ensures the exact hydrogen concentration needed to penetrate copper grain boundaries and reduce cuprous oxide. This reaction generates internal pressure via water vapor, creating the micro-cracks essential for turning solid wire into fine powder.

The Mechanism of Hydrogen Embrittlement

Creating the Reducing Atmosphere

The primary function of the gas mixing system is to maintain a stable, precise blend of 40% hydrogen and 60% nitrogen.

This specific ratio creates a reducing atmosphere, which is distinct from a standard inert environment.

The consistency provided by the mixer ensures that the atmosphere remains stable throughout the annealing cycle, preventing process variability.

Targeting Grain Boundaries

The system enables the control necessary for hydrogen to diffuse deep into the copper grain boundaries.

Once it penetrates the material, the hydrogen actively locates and reacts with cuprous oxide inherent in the copper.

This internal chemical interaction is the defining characteristic of the syngas annealing process.

Generating Micro-Cracks

The reaction between the diffused hydrogen and the cuprous oxide generates high-pressure water vapor inside the metal.

Because this vapor is trapped within the grain boundaries, it exerts significant stress on the material structure.

This pressure forms vacancies and micro-cracks, causing the copper to become brittle rather than ductile.

The Criticality of Precision

Consequences of Incorrect Ratios

Without a dedicated mixing system, fluctuating gas ratios will lead to inconsistent hydrogen embrittlement.

If the hydrogen concentration drops below the required threshold, the reaction will fail to generate sufficient water vapor pressure.

This results in wire that retains its ductility, making the subsequent mechanical crushing phase inefficient or completely ineffective.

Optimizing Production Goals

To maximize the quality of copper powder production, the gas mixing system must be viewed as a critical control point rather than a passive utility.

- If your primary focus is powder consistency: Ensure the gas mixer maintains the strict 40% hydrogen ratio to guarantee uniform embrittlement and grain structure across the entire wire batch.

- If your primary focus is crushing efficiency: Prioritize precise hydrogen control to maximize the reduction of cuprous oxide, ensuring the wire is sufficiently brittle to minimize energy usage during mechanical crushing.

By mastering the atmospheric composition, you transform a standard annealing process into a precise tool for material modification.

Summary Table:

| Parameter | Specification | Role in Syngas Annealing |

|---|---|---|

| Gas Composition | 40% Hydrogen / 60% Nitrogen | Creates a strictly controlled reducing atmosphere |

| Mechanism | Hydrogen Embrittlement | Targets cuprous oxide to create internal micro-cracks |

| Material Change | Ductile to Brittle | Prepares solid copper wire for mechanical crushing |

| Key Outcome | Consistent Water Vapor Pressure | Ensures uniform structural weakening of grain boundaries |

Optimize Your Copper Powder Quality with KINTEK

Precision in gas composition is the difference between inefficient processing and high-quality material output. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, and Vacuum systems that integrate seamlessly into your high-temperature workflows. Whether you require customized atmosphere control or robust lab furnaces, our solutions are designed to ensure your specific hydrogen-nitrogen ratios remain stable for perfect embrittlement.

Ready to enhance your lab's efficiency and powder consistency? Contact our technical experts today to find the perfect customizable solution for your unique needs.

Visual Guide

References

- Falah Mustafa Al-Saraireh. The Effect of Annealing Conditions on Copper's Brittleness and Powder Production Efficiency. DOI: 10.21062/mft.2025.035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

People Also Ask

- What is the function of vacuum-sealed quartz jackets in sample encapsulation? Ensure Purity in Material Synthesis

- What additional convenience feature is included with the water circulating vacuum pump? Discover Easy Mobility and More

- What functions do carbon black and carbon fiber felt serve as insulation? Maximize Efficiency in 3000°C Furnaces

- What are the technical advantages of using high-purity quartz tubes? Optimize Heat and Purity in Combustion Analysis

- Why is a high-precision mass flow controller (MFC) necessary in ferronickel alloy smelting? Ensure Metal Purity

- How does a high-pressure reaction kettle facilitate 3D core-shell formation? Mastering Hydrothermal Catalyst Synthesis

- Why are high-purity alumina crucibles used for containing molten high-silicon steel? Ensure Purity & Thermal Stability

- What are the key properties of quartz tubes that make them versatile across industries? Discover Their Thermal, Chemical, and Optical Benefits