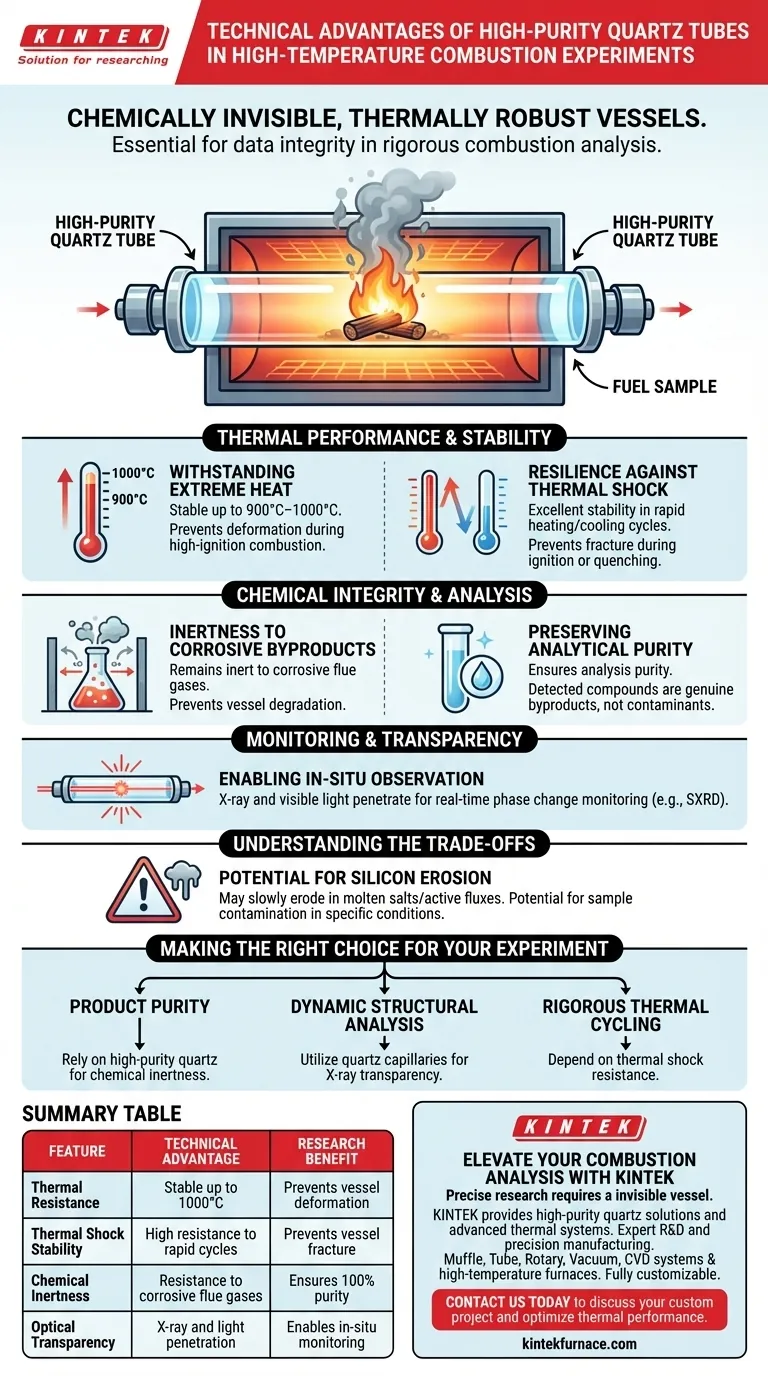

High-purity quartz tubes serve as chemically invisible, thermally robust vessels essential for maintaining data integrity during rigorous combustion analysis. These components provide a critical combination of thermal resistance up to 900°C–1000°C, immunity to thermal shock during rapid temperature changes, and chemical inertness against corrosive flue gases.

The Core Value In high-temperature analysis, the reaction vessel must contain the experiment without participating in it. High-purity quartz ensures that the structural changes or chemical byproducts you measure are from your sample, not degradation or contamination from the tube itself.

Thermal Performance and Stability

Withstanding Extreme Heat

High-purity quartz offers exceptional thermal resistance, maintaining structural integrity in environments exceeding 900°C.

specialized configurations, such as capillaries used in non-isothermal reduction processes, can remain stable up to 1000°C. This allows for the combustion of fuels that require high ignition temperatures without softening or deforming the vessel.

Resilience Against Thermal Shock

Combustion experiments often involve rapid heating and cooling cycles.

Quartz tubes possess excellent thermal shock stability, meaning they can withstand frequent, drastic temperature fluctuations without fracturing. This durability is critical for preventing catastrophic vessel failure during the ignition or quenching phases of an experiment.

Chemical Integrity and Analysis

Inertness to Corrosive Byproducts

Combustion processes frequently generate corrosive flue gases that react with standard glass or metal vessels.

High-purity quartz remains chemically inert in these environments. It does not react with the corrosive gases produced during fuel combustion, preventing the vessel from degrading or altering the chemical composition of the reaction atmosphere.

Preserving Analytical Purity

The primary goal of combustion experimentation is the accurate analysis of combustion products.

Because the quartz tube resists chemical interaction, it ensures the purity of the analysis. Researchers can be confident that the detected compounds are genuine byproducts of the fuel, rather than contaminants leached from the reaction vessel.

Monitoring and Transparency

Enabling In-Situ Observation

Beyond thermal and chemical properties, high-purity quartz offers superior transparency.

In advanced applications like Synchrotron X-ray Diffraction (SXRD), quartz capillaries allow high-energy beams (e.g., 55 keV) to penetrate the sample. This permits continuous dynamic monitoring of phase changes and structural information in real-time while the sample is under heat.

Understanding the Trade-offs

Potential for Silicon Erosion

While generally inert, quartz is not universally resistant to all chemical environments.

In specific conditions involving molten salts or active fluxes, the inner wall of the quartz tube can slowly erode. While some synthesis techniques intentionally exploit this to use the tube as a silicon source, in a pure combustion experiment, this represents a potential vector for sample contamination if the specific reactants are incompatible with silica.

Making the Right Choice for Your Experiment

Select your reaction vessel based on the specific parameters of your analysis:

- If your primary focus is product purity: Rely on high-purity quartz for its chemical inertness to ensure flue gases remain uncontaminated by the vessel walls.

- If your primary focus is dynamic structural analysis: Utilize quartz capillaries to leverage their X-ray transparency for real-time monitoring of phase changes up to 1000°C.

- If your primary focus is rigorous thermal cycling: Depend on the material's thermal shock resistance to prevent fractures during rapid heating and cooling sequences.

Ultimately, high-purity quartz is the definitive choice when the isolation of the sample environment is as critical as the reaction itself.

Summary Table:

| Feature | Technical Advantage | Research Benefit |

|---|---|---|

| Thermal Resistance | Stable up to 1000°C | Prevents vessel deformation during ignition |

| Thermal Shock Stability | High resistance to rapid cooling/heating | Prevents vessel fracture during quenching |

| Chemical Inertness | Resistance to corrosive flue gases | Ensures 100% purity of combustion byproducts |

| Optical Transparency | X-ray and visible light penetration | Enables in-situ monitoring of phase changes |

Elevate Your Combustion Analysis with KINTEK

Precise research requires a vessel that stays invisible. KINTEK provides high-purity quartz solutions and advanced thermal systems designed to protect your data integrity.

Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces. All our systems are fully customizable to meet the unique demands of your experimental setup.

Ready to optimize your lab’s thermal performance? Contact us today to discuss your custom project and see how KINTEK can bring superior reliability to your high-temperature applications.

Visual Guide

References

- Silin Zeng, Baosheng Jin. Experimental study on No<sub>x</sub> emission and nitrogen conversion characteristics of a coal gangue blended with coal washing mixture. DOI: 10.1088/1742-6596/3013/1/012035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are high-purity quartz tubes and quartz boats preferred for plastic pyrolysis? Ensure Precise, Pure Results

- What is the importance of high-precision mass flow controllers in gas distribution systems? Ensure Data Accuracy.

- What factors should be considered when selecting an alumina ceramic furnace tube? Ensure Safety and Performance in High-Temp Processes

- What is the key technological improvement in the circulating water vacuum pump? Discover the Self-Contained Closed-Loop System

- Why are a vacuum pump and a flame sealing system required in the gas-phase deposition for palladium? Key Role Explained

- Why is vacuum sealing in high-purity quartz tubes necessary for the synthesis of FexTaSe2? Master Crystal Growth

- What is the function of a high-pressure stainless steel autoclave? Master Hydrothermal Synthesis of Nanomaterials

- What role does a covered alumina or aluminum alloy crucible play in g-C3N4 synthesis? Maximize Yield and Quality