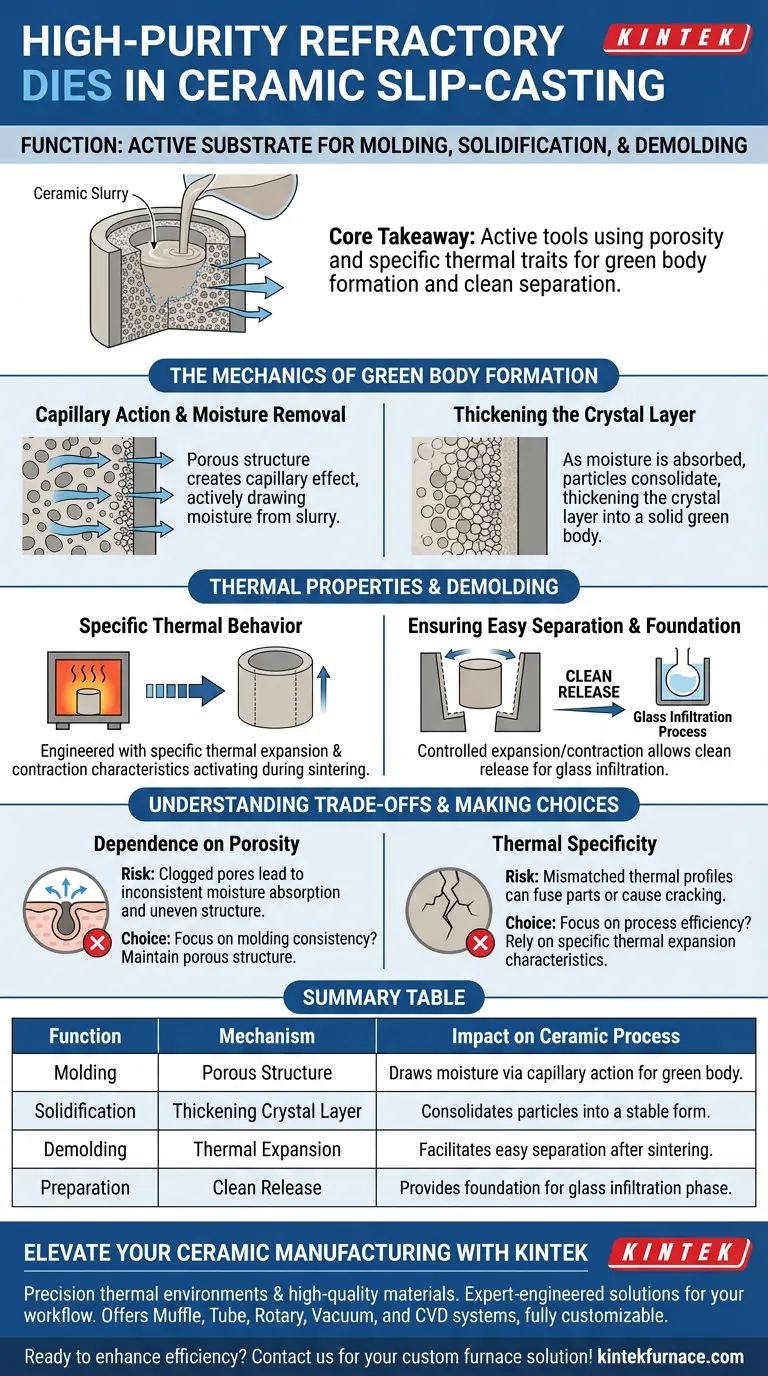

High-purity refractory dies serve as the active substrate for molding ceramic slurry. They utilize their inherent porous structure to extract moisture via capillary action, thickening the material's crystal layer to create a solid "green body." Furthermore, their specific thermal properties facilitate the separation of the ceramic core after sintering, preparing it for subsequent glass infiltration.

Core Takeaway: These dies are not just molds; they are active tools that use porosity to solidify liquid slurry and specific thermal expansion traits to ensure clean separation, linking the molding phase to the glass infiltration process.

The Mechanics of Green Body Formation

Capillary Action and Moisture Removal

The refractory die functions through its porous structure. This porosity creates a capillary effect that actively draws moisture out of the ceramic slurry poured into the mold.

Thickening the Crystal Layer

As the die absorbs moisture, the solid particles within the slurry begin to consolidate. This process causes the crystal layer to thicken against the die walls, gradually transforming the liquid slurry into a solid, shaped form known as a green body.

Thermal Properties and Demolding

Specific Thermal Behavior

The utility of these dies extends into the heating phase. They are engineered with specific thermal expansion and contraction characteristics that activate during sintering.

Ensuring Easy Separation

Because the die expands and contracts at a specific rate, it allows for a clean release. The sintered porous ceramic core can be easily separated from the mold without damaging the delicate structure of the newly formed object.

Foundation for Next Steps

This separation is critical for the manufacturing workflow. A clean release provides the necessary foundation for the glass infiltration process, which strengthens and finalizes the ceramic component.

Understanding the Trade-offs

Dependence on Porosity

The efficiency of the process relies entirely on the die's capillary action. If the die's pores become clogged or damaged, moisture absorption becomes inconsistent, leading to uneven wall thickness or structural weaknesses in the green body.

Thermal Specificity

The advantage of easy separation relies on precise thermal matching. If the sintering temperatures do not align with the die's specific expansion and contraction profiles, you risk fusing the part to the mold or cracking the ceramic core during the cooling phase.

Making the Right Choice for Your Goal

To maximize the effectiveness of high-purity refractory dies in your process, consider the following:

- If your primary focus is molding consistency: Ensure the die's porous structure is maintained to support the uniform capillary action required for thickening the crystal layer.

- If your primary focus is process efficiency: Rely on the die's specific thermal expansion characteristics to streamline the separation phase and reduce breakage rates.

By leveraging both the absorptive and thermal properties of the die, you ensure a stable transition from liquid slurry to a finished core ready for infiltration.

Summary Table:

| Function | Mechanism | Impact on Ceramic Process |

|---|---|---|

| Molding | Porous Structure | Draws moisture via capillary action to create the green body. |

| Solidification | Thickening Crystal Layer | Consolidates slurry particles into a solid, stable form. |

| Demolding | Thermal Expansion | Facilitates easy separation of the core after sintering. |

| Preparation | Clean Release | Provides a perfect foundation for the glass infiltration phase. |

Elevate Your Ceramic Manufacturing with KINTEK

Precision in the slip-casting process begins with the right thermal environment and high-quality materials. KINTEK provides expert-engineered solutions designed to optimize your production workflow.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique sintering and infiltration needs.

Ready to enhance your lab's efficiency and achieve superior material consistency?

Contact us today to discuss your custom furnace solution!

Visual Guide

References

- Nestor Washington Solís Pinargote, Pavel Peretyagin. Materials and Methods for All-Ceramic Dental Restorations Using Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) Technologies—A Brief Review. DOI: 10.3390/dj12030047

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the advantages of using a Type B thermocouple for 1600°C slag reduction? Precision in Ultra-High Heat

- What is the purpose of using a high-purity ceramic crucible with a sealed lid during the thermal treatment of biochar?

- What role do vacuum pumps and chambers play in the Reduced Pressure Test? Mastering Aluminum Quality Control

- How does a laboratory drying oven contribute to maintaining material activity? Preserve Catalyst Performance Easily

- What roles do the Stockbarger method and vacuum-sealed quartz ampoules play in NaCl:Li and KCl:Na crystal growth?

- What are the functions of Silica Quartz Tubes and quartz glass wool in RDF pyrolysis? Enhancing Experimental Accuracy

- What are the key properties of quartz tubes that make them versatile across industries? Discover Their Thermal, Chemical, and Optical Benefits

- Why is the use of casting flux necessary during the melting of aluminum-based alloys? Protect Your Chemical Integrity