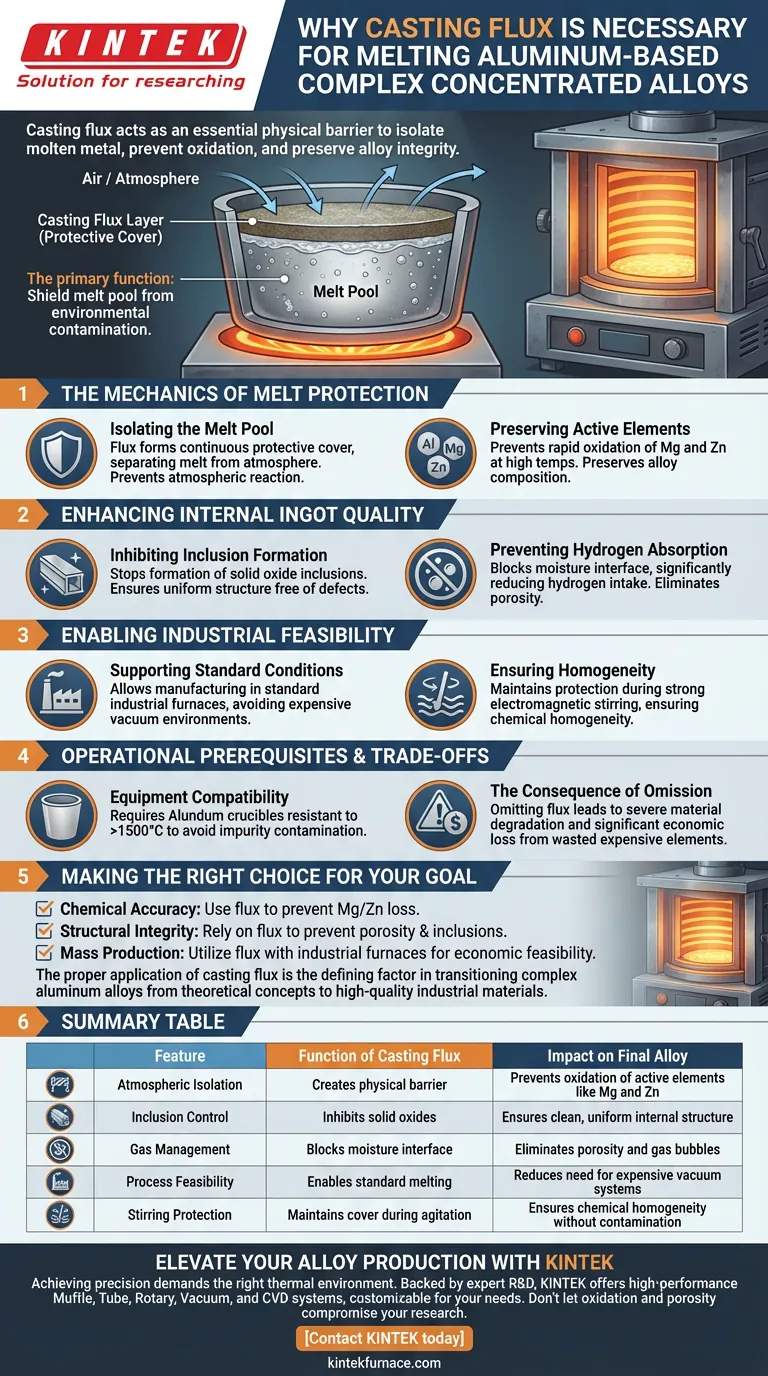

Casting flux acts as an essential physical barrier during the melting process of aluminum-based complex concentrated alloys to isolate the molten metal from the atmosphere. This isolation is critically necessary to prevent the oxidation of highly active elements—specifically magnesium and zinc—thereby reducing metal loss and preserving the chemical integrity of the alloy.

The primary function of casting flux is to shield the melt pool from environmental contamination. By inhibiting oxidation and hydrogen absorption, flux ensures the final ingot maintains high internal quality and accurate chemical composition.

The Mechanics of Melt Protection

Isolating the Melt Pool

When melting aluminum-based alloys, the surface of the molten metal is highly susceptible to reacting with the surrounding air.

Casting flux melts to form a continuous protective cover over the liquid metal.

This barrier physically separates the melt pool from the atmosphere, effectively neutralizing the threat of atmospheric reaction.

Preserving Active Elements

Aluminum-based complex concentrated alloys often contain high percentages of active metallic elements, such as magnesium and zinc.

These elements are prone to rapid oxidation when exposed to air at high temperatures.

Without the isolation provided by the flux, these valuable components would oxidize and be lost, altering the intended composition of the alloy.

Enhancing Internal Ingot Quality

Inhibiting Inclusion Formation

Oxidation does not just result in material loss; it creates solid oxides that can become trapped within the metal.

The application of casting flux inhibits the formation of these oxide inclusions.

By keeping the melt clean, the flux ensures the final material has a uniform structure free of particulate defects.

Preventing Hydrogen Absorption

Molten aluminum has a high affinity for absorbing hydrogen from moisture in the atmosphere.

Hydrogen absorption leads to porosity (gas bubbles) in the solidified metal, which severely weakens the alloy.

The flux barrier blocks the interface between the air and the metal, significantly reducing the intake of hydrogen.

Enabling Industrial Feasibility

Supporting Standard Manufacturing Conditions

The use of casting flux allows these complex alloys to be manufactured under standard industrial conditions.

Without flux, production might be restricted to expensive, high-purity laboratory vacuum environments to prevent oxidation.

This capability demonstrates the economic feasibility of mass-producing these alloys using industrial-grade induction furnaces.

Ensuring Homogeneity

Industrial induction furnaces utilize electromagnetic induction to provide a strong stirring effect.

While this stirring ensures chemical homogeneity of the alloying components, it can also expose more surface area to the air.

The flux interacts with this process by maintaining protection even during the agitation required for mixing high-alloy components.

Operational Prerequisites and Trade-offs

Equipment Compatibility

While flux protects the metal from the air, the container holding the metal must also be chemically stable.

Alundum crucibles are required due to their high refractoriness and resistance to reaction at temperatures exceeding 1500°C.

Using a less stable crucible could lead to impurity contamination, negating the purity benefits provided by the flux.

The Consequence of Omission

Omitting casting flux is not a viable cost-saving measure for these specific alloys.

The trade-off for skipping this step is a severe degradation of material properties and significant economic loss due to the waste of expensive elements like magnesium.

Making the Right Choice for Your Goal

To ensure the successful production of aluminum-based complex concentrated alloys, consider the following principles:

- If your primary focus is Chemical Accuracy: You must use casting flux to prevent the loss of active elements like magnesium and zinc through oxidation.

- If your primary focus is Structural Integrity: Rely on flux to prevent hydrogen porosity and oxide inclusions that weaken the final ingot.

- If your primary focus is Mass Production: Utilize casting flux in conjunction with industrial induction furnaces to achieve economic feasibility without relying on vacuum systems.

The proper application of casting flux is the defining factor in transitioning complex aluminum alloys from theoretical concepts to high-quality industrial materials.

Summary Table:

| Feature | Function of Casting Flux | Impact on Final Alloy |

|---|---|---|

| Atmospheric Isolation | Creates a physical barrier between melt and air | Prevents oxidation of active elements like Mg and Zn |

| Inclusion Control | Inhibits the formation of solid oxides | Ensures a clean, uniform internal structure |

| Gas Management | Blocks moisture interface to stop hydrogen intake | Eliminates porosity and gas bubbles in the ingot |

| Process Feasibility | Enables melting in standard induction furnaces | Reduces the need for expensive vacuum environments |

| Stirring Protection | Maintains cover during electromagnetic agitation | Ensures chemical homogeneity without contamination |

Elevate Your Alloy Production with KINTEK

Achieving chemical precision in aluminum-based complex concentrated alloys requires more than just flux—it demands the right thermal environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces customizable for your unique metallurgical needs.

Don't let oxidation and porosity compromise your research or production. Contact KINTEK today to discover how our advanced heating solutions can optimize your melting process and ensure superior material homogeneity.

Visual Guide

References

- Compositional Design, Microstructure, and Thermal Processing of Aluminum-Based Complex Concentrated Alloys. DOI: 10.3390/cryst15010088

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the specific function of the water circulation cooler in zirconium sponge processing? Key for Purity & Safety

- Why are ceramic crucibles required for the high-temperature calcination of dolomite? Ensure High-Purity Results

- Why is a platinum-gold alloy crucible utilized during the glass melting process? Achieve Unmatched Purity

- How do high-precision mass flow controllers assist in the formation of superlattice structures? Mastery of 2D CVD

- Why are magnesium oxide-stabilized zirconia crucibles used for melting alloys? High-Temp Stability up to 1900°C

- What are the main reasons for the alumina furnace tube being prone to breaking? Prevent Costly Failures with Expert Tips

- Why use high-purity graphite for β-Ga2O3 annealing? Key to Thermal Precision & Safety

- What is the function of high-purity alumina crucibles in NRBBO:Eu2+ sintering? Ensure Pure Phosphor Synthesis