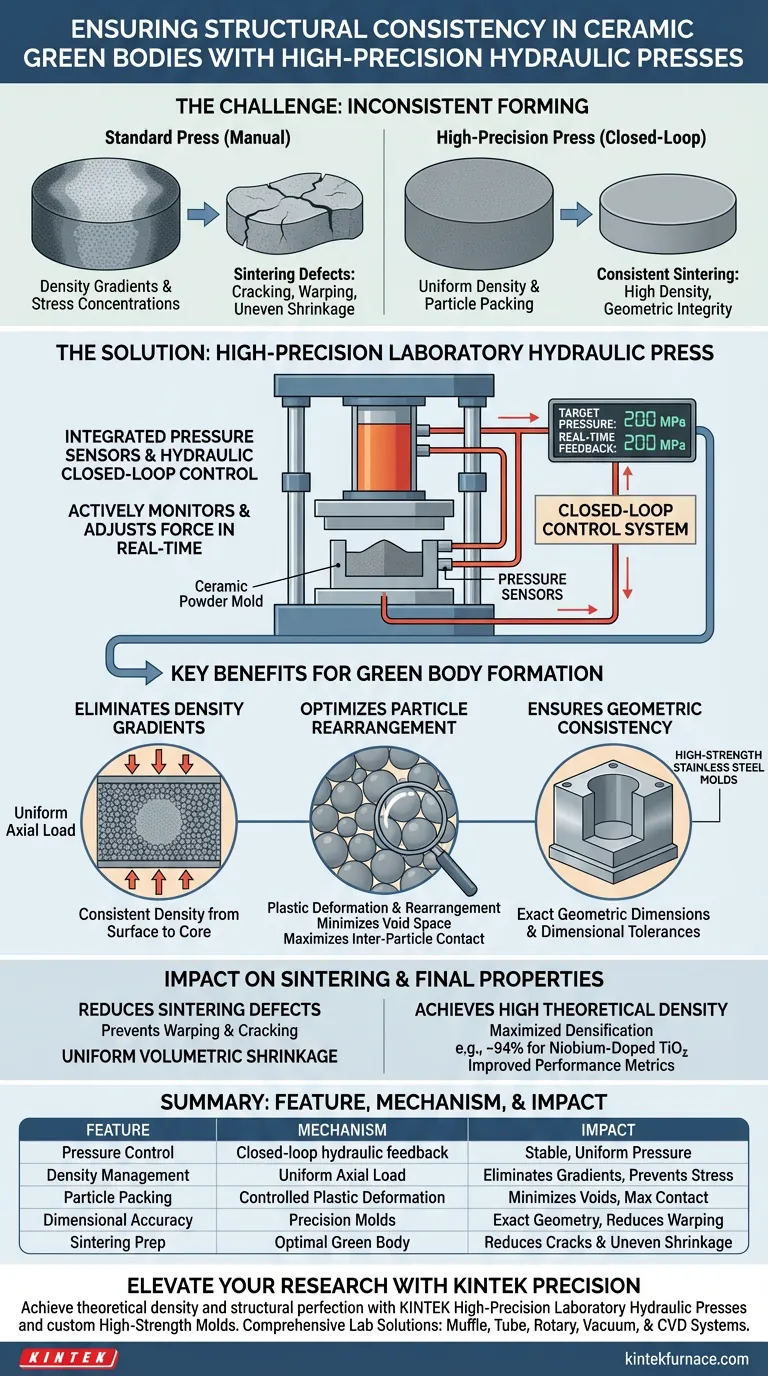

High-precision laboratory hydraulic presses ensure structural consistency by integrating high-sensitivity pressure sensors with a hydraulic closed-loop control system. This technology actively monitors and adjusts the force in real-time to deliver extremely stable and uniform pressure loads throughout the forming process. By ensuring precise pressure distribution, the press forces powder particles to fully rearrange and pack tightly, effectively eliminating internal density gradients and localized stress concentrations.

By achieving optimal particle packing and eliminating density variations in the "green" state, high-precision pressing significantly reduces the risk of deformation, cracking, and uneven shrinkage during the subsequent high-temperature sintering stage.

The Mechanics of Pressure Control

The Closed-Loop System

The core differentiator of a high-precision press is its closed-loop control system. Unlike standard manual presses, this system uses feedback from sensitive pressure sensors to automatically regulate the hydraulic force.

This ensures that the applied load remains constant and accurate, regardless of slight variations in the hydraulic fluid or mechanical resistance.

Eliminating Density Gradients

Inconsistent pressure leads to density gradients—areas where powder is packed tighter in some spots than others. A high-precision press mitigates this by applying a uniform axial load.

This uniformity ensures that the density is consistent from the surface to the core of the green body.

Optimizing Particle Rearrangement

The application of stable, multi-ton loads forces loose powder particles to undergo plastic deformation and rearrangement.

This mechanical compression minimizes void space and maximizes inter-particle contact. This is physically essential for creating a cohesive solid from loose nanopowders or composite materials.

The Role of Tooling and Geometry

Interaction with Precision Molds

The press does not work in isolation; it requires pressure-resistant high-strength stainless steel molds.

While the press provides the precise force (often reaching hundreds of megapascals), the rigid mold ensures the material is confined without lateral deformation.

Geometric Consistency

By combining precise axial force with rigid tooling, the system produces green bodies with exact geometric dimensions.

For example, maintaining specific diameters and thicknesses (e.g., 13mm x 3mm) is critical for repeatability in subsequent processing steps like Hot Isostatic Pressing (HIP).

Impact on Sintering and Final Properties

Reducing Sintering Defects

The structural consistency achieved during pressing is the primary defense against warping and cracking during sintering.

If a green body has uneven density, it will shrink unevenly when heated. A uniform green body promotes uniform volumetric shrinkage.

Achieving Theoretical Density

Proper initial packing is a prerequisite for high final density. For materials like niobium-doped titanium dioxide, uniform pressing enables the final product to reach high percentages (e.g., 94%) of theoretical density.

This densification is directly linked to the accuracy of subsequent performance metrics, such as electrical measurements.

Understanding the Trade-offs

The Limit of Axial Pressing

While high-precision presses offer excellent control, they typically apply uniaxial pressure (pressure from one direction).

Even with advanced control, friction between the powder and the mold walls can create slight density variations in very tall or complex parts.

Mold Dependability

The precision of the press is entirely dependent on the quality of the mold.

If the mold cannot withstand the massive axial pressures without elastic deformation, the active control system of the press cannot compensate for the resulting geometric inaccuracies.

Making the Right Choice for Your Goal

To maximize the effectiveness of a high-precision hydraulic press, align your process parameters with your specific outcomes:

- If your primary focus is Defect Prevention: Prioritize the stability of the closed-loop control to eliminate stress concentrations that lead to cracks during heating.

- If your primary focus is High Sintered Density: Ensure the press can deliver sufficiently high pressure (hundreds of MPa) to force maximum particle plastic deformation.

- If your primary focus is Geometric Accuracy: Pair the hydraulic press with high-strength, non-deforming stainless steel molds to maintain strict dimensional tolerances.

Precision in the green stage is the single most controllable variable for ensuring the success of the final ceramic product.

Summary Table:

| Feature | High-Precision Press Mechanism | Impact on Ceramic Quality |

|---|---|---|

| Pressure Control | Closed-loop hydraulic feedback with sensitive sensors | Ensures ultra-stable, uniform pressure and repeatability. |

| Density Management | Uniform axial load application | Eliminates density gradients and prevents internal stress. |

| Particle Packing | Controlled plastic deformation of powder | Minimizes void space and maximizes inter-particle contact. |

| Dimensional Accuracy | Interaction with high-strength stainless steel molds | Produces exact geometric dimensions to reduce warping. |

| Sintering Prep | Optimal green body formation | Significantly reduces cracking and uneven shrinkage during firing. |

Elevate Your Material Research with KINTEK Precision

Consistency in the 'green' state is the foundation of flawless ceramic performance. Backed by expert R&D and manufacturing, KINTEK offers high-precision Laboratory Hydraulic Presses and high-strength molds designed to eliminate density variations and sintering defects. Our comprehensive range of lab high-temp equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—is fully customizable to meet your unique materials science requirements.

Ready to achieve theoretical density and structural perfection? Contact us today to find your custom solution!

Visual Guide

References

- Zhanjiang Pei, Yanling Yu. The Enhancing Effect of Biochar Derived from Biogas Residues on the Anaerobic Digestion Process of Pig Manure Water. DOI: 10.3390/fermentation10120644

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a laboratory graphite box play during the selenization of CBTSe thin films? Key Synthesis Benefits

- What manufacturing processes rely on laboratory furnaces? Precision Heat Treatment for Advanced Materials

- What is the primary function of a high-energy planetary ball mill? Unlock Nanoscale Ceramic Pretreatment

- Why are high-purity alumina grinding balls used for Al2O3/TiC milling? Master Chemical Consistency

- What is the primary function of an alumina crucible in preparing B2O3–ZnO–BaO shielding glass? Process Secrets Revealed

- What is the core function of a planetary ball mill in Bi2Te3 alloying? Drive Solid-State Reaction & Nanoscale Refinement

- What are the primary uses of quartz tubes in laboratory settings? Essential for High-Temperature Material Processing

- What is the primary function of an alumina crucible in CsV3Sb5 growth? Ensure High Purity and Thermal Stability