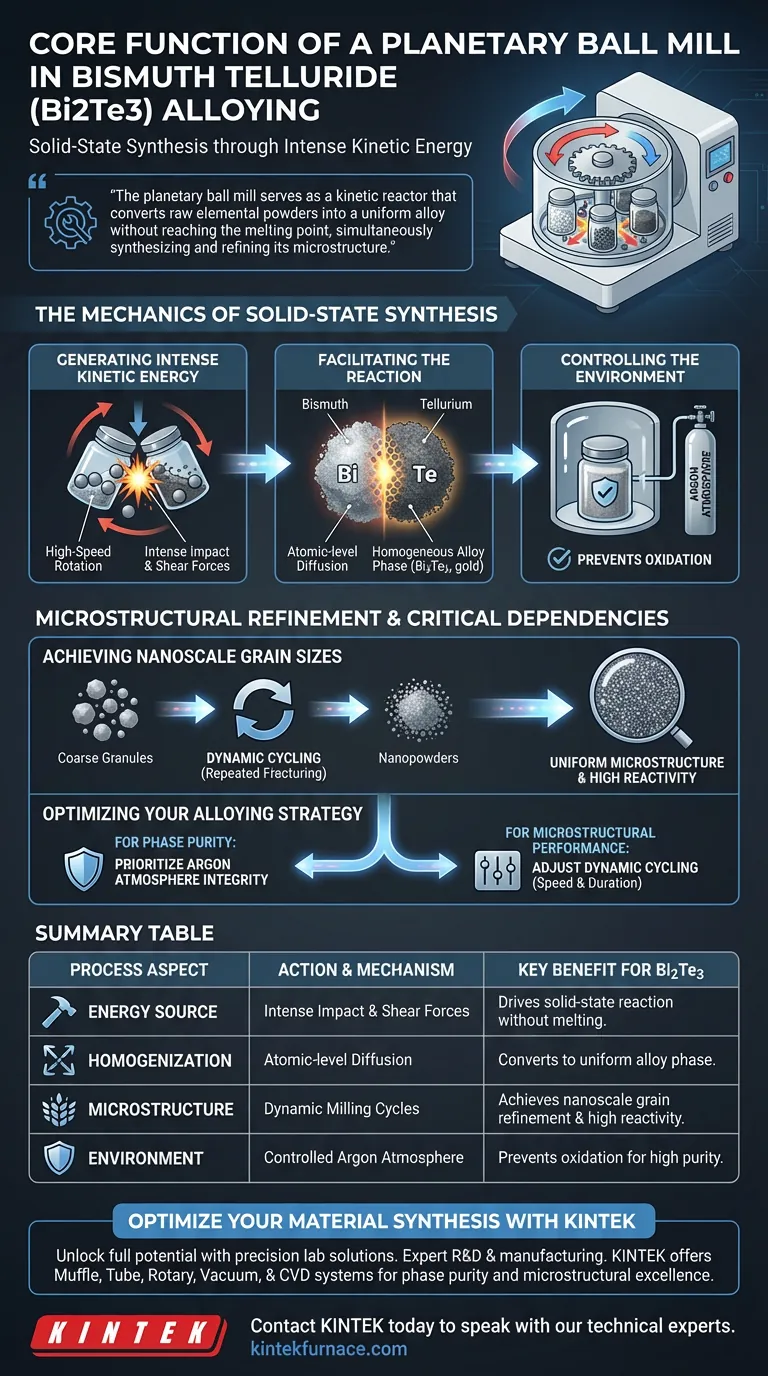

The core function of a planetary ball mill in the processing of Bismuth Telluride (Bi2Te3) is to drive a solid-state reaction through mechanical energy rather than heat alone. By utilizing high-speed rotation to generate intense impact and shear forces, the mill physically forces high-purity bismuth and tellurium powders to react and merge into a homogeneous alloy within a protective argon atmosphere.

The planetary ball mill serves as a kinetic reactor that converts raw elemental powders into a uniform alloy without reaching the melting point. Its critical value lies in simultaneously synthesizing the material and refining its microstructure, producing reactive nanopowders that are essential for high-performance applications.

The Mechanics of Solid-State Synthesis

Generating Intense Kinetic Energy

The planetary ball mill operates by subjecting the grinding jars to high-speed rotation.

This movement creates a complex environment where the grinding media (balls) collide with the material and the jar walls. These collisions generate the intense impact and shear forces necessary to fracture and cold-weld the particles repeatedly.

Facilitating the Reaction

Unlike traditional melting methods, this process relies on a solid-state reaction.

The mechanical energy introduced by the mill breaks down the crystal structures of the raw bismuth and tellurium. This allows the elements to diffuse into one another at the atomic level, converting the distinct powders into a single, homogeneous alloy phase.

Controlling the Environment

The integrity of the Bi2Te3 alloy relies heavily on the processing environment.

The milling occurs within a controlled argon atmosphere. This prevents oxidation during the high-energy process, ensuring that the final alloy maintains the high purity required for semiconductor or thermoelectric applications.

Microstructural Refinement

Achieving Nanoscale Grain Sizes

Beyond simple mixing, the planetary ball mill is a tool for grain refinement.

The dynamic cycling of the milling process continually fractures the material. Over time, this significantly reduces the particle size, resulting in the production of nanopowders rather than coarse granules.

Enhancing Material Reactivity

The reduction of particle size has a direct impact on the material's properties.

By creating a uniform microstructure composed of nanopowders, the surface area-to-volume ratio increases drastically. This leads to high reactivity in the resulting powder, which is often a prerequisite for subsequent consolidation steps like sintering.

Critical Process Dependencies

The Necessity of Dynamic Cycling

Achieving the desired alloy properties is not immediate.

The process relies on the dynamic cycling of the mill over a set duration. Without sufficient cycling time and energy input, the material may fail to reach a truly homogeneous state or achieve the necessary grain refinement.

Atmosphere Integrity

The "mechanical" aspect of thermomechanical alloying generates heat and fresh surfaces.

If the argon atmosphere is compromised, the highly reactive fresh surfaces of the bismuth and tellurium will oxidize immediately. This renders the material useless for high-efficiency applications, underscoring the need for rigorous environmental control.

Optimizing Your Alloying Strategy

If your primary focus is Phase Purity:

- Prioritize the integrity of the controlled argon atmosphere to prevent oxidation during the high-energy solid-state reaction.

If your primary focus is Microstructural Performance:

- Adjust the dynamic cycling parameters (speed and duration) to maximize impact forces, ensuring the production of fine, uniform nanopowders.

The planetary ball mill is not just a grinder; it is a kinetic instrument that engineers the fundamental structure of Bismuth Telluride to unlock its full potential.

Summary Table:

| Process Aspect | Action & Mechanism | Key Benefit for Bi2Te3 |

|---|---|---|

| Energy Source | Intense Impact & Shear Forces | Drives solid-state reaction without reaching melting points. |

| Homogenization | Atomic-level Diffusion | Converts elemental powders into a single, uniform alloy phase. |

| Microstructure | Dynamic Milling Cycles | Achieves nanoscale grain refinement and high reactivity. |

| Environment | Controlled Argon Atmosphere | Prevents oxidation to maintain high purity for semiconductors. |

Optimize Your Material Synthesis with KINTEK

Unlock the full potential of your Bismuth Telluride alloys with precision laboratory solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab high-temp furnaces or fully customizable systems for unique research needs, we provide the tools to ensure phase purity and microstructural excellence.

Ready to elevate your alloying process? Contact KINTEK today to speak with our technical experts.

Visual Guide

References

- Mohamed Abdelnaser Mansour, Ahmed Abdelmoneim. Enhancing the thermoelectric properties for hot-isostatic-pressed Bi2Te3 nano-powder using graphite nanoparticles. DOI: 10.1007/s10854-024-12389-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What role does a mechanical vacuum pump system play in cerium dioxide reduction? Boost Efficiency at Lower Pressures

- What is the function of a high-precision mass flow controller (MFC) in CdS nanobelt vapor deposition?

- Why must fuel injectors used in high-temperature furnace systems incorporate a cooling function? Prevent Coking Today

- What is the critical role of a mechanical vacuum pump in WS2 gas sensor prep? Ensure High Purity & Performance

- How does the design of a graphite box optimize the sulfurization of Sb thin films? Key Insights for Film Uniformity

- Why is a Zirconia (ZrO2) oxygen sensor used for CaO-Al2O3-VOx slag research? Achieve Precise Redox Control

- What role does a rotary evaporator serve in the processing of banana inflorescence extracts? Maximize Bioactive Recovery

- Why is a laboratory vacuum drying oven necessary for processing nano MOFs? Preserve nLn-bdc Structural Integrity