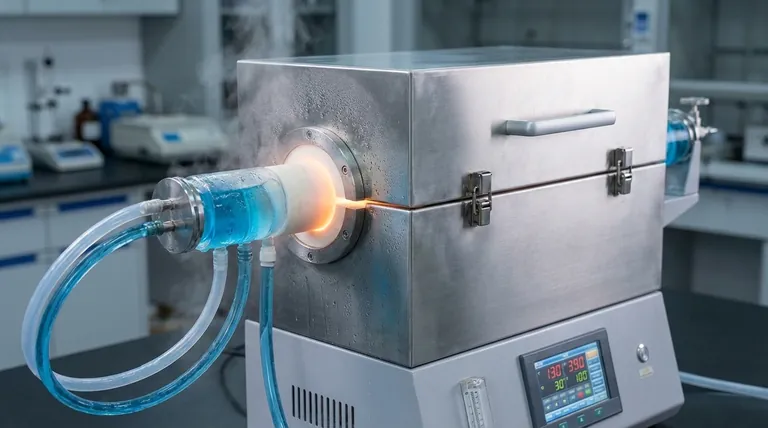

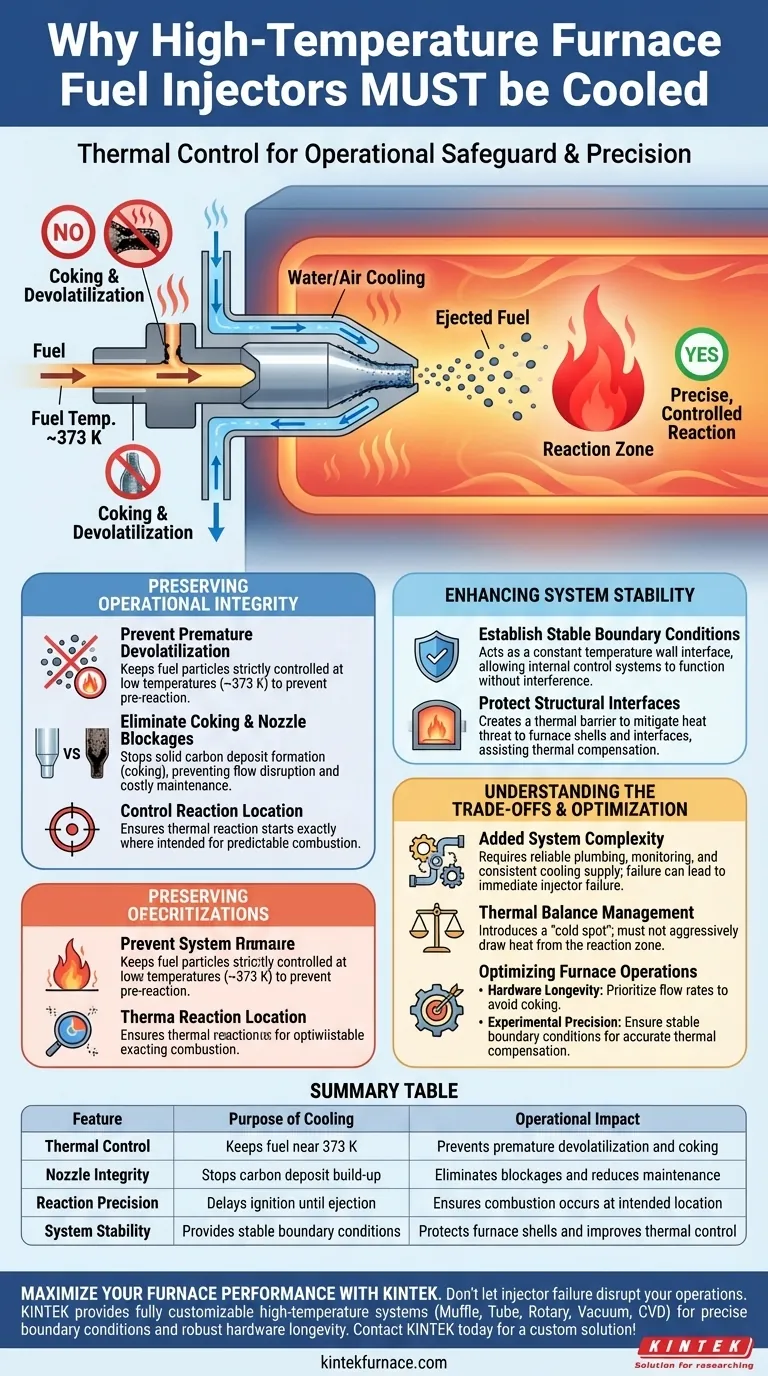

In high-temperature furnace environments, cooling is a critical operational safeguard. Fuel injectors must utilize water or air cooling to maintain fuel temperatures at approximately 373 K, strictly preventing the fuel from reacting before it leaves the nozzle. This thermal control is the only way to ensure the injector does not suffer from internal clogging or structural failure.

By keeping fuel particles at low temperatures until ejection, cooling systems prevent premature devolatilization and internal coking. This ensures that thermal reactions occur precisely where intended—inside the chamber, not inside the hardware.

Preserving Operational Integrity

Preventing Premature Devolatilization

The primary function of the cooling system is to keep fuel particles strictly controlled at low levels (around 373 K).

If the fuel heats up too early, it begins to devolatilize inside the injector body. This alters the chemical composition of the fuel before it ever reaches the reaction zone.

Eliminating Coking and Nozzle Blockages

When fuel overheats within the confined space of an injector, it leads to "coking"—the formation of solid carbon deposits.

Without active cooling, these deposits would rapidly accumulate. This accumulation inevitably leads to physical nozzle blockages, disrupting flow and requiring expensive maintenance.

Controlling Reaction Location

Precision is paramount in high-temperature systems.

The cooling mechanism ensures that the fuel particles begin their thermal reaction exactly at the intended location within the furnace. By preventing early ignition inside the nozzle, the system maintains a predictable and efficient combustion profile.

Enhancing System Stability

Establishing Stable Boundary Conditions

Beyond protecting the fuel, the cooling system acts as a constant temperature wall interface.

This establishes stable external boundary conditions for the furnace. Stability here allows the internal control systems to function without interference from fluctuating injector temperatures.

Protecting Structural Interfaces

High-temperature environments pose a threat to the structural integrity of furnace shells and specific interfaces.

The cooling system mitigates this risk by maintaining a thermal barrier. This assists the internal temperature control system in achieving accurate thermal compensation and protects the physical hardware.

Understanding the Trade-offs

Added System Complexity

Implementing water or air cooling adds a layer of mechanical complexity to the furnace design.

It requires reliable plumbing, monitoring, and a consistent supply of the cooling medium. A failure in the cooling supply line can lead to immediate injector failure.

Thermal Balance Management

While cooling is necessary for the injector, it introduces a "cold spot" into a hot environment.

Operators must ensure the cooling system does not aggressively draw heat away from the reaction zone itself. The goal is to cool the hardware and fuel, not the furnace chamber.

Optimizing Furnace Operations

To ensure long-term reliability and precision in your high-temperature applications, consider the following:

- If your primary focus is hardware longevity: Prioritize cooling flow rates that strictly maintain the injector interface below the coking threshold to prevent nozzle blockages.

- If your primary focus is experimental precision: Ensure the cooling system provides a stable boundary condition to assist the internal temperature control system in maintaining accurate thermal compensation.

The correct application of injector cooling transforms a volatile, clog-prone setup into a consistent, high-precision reaction system.

Summary Table:

| Feature | Purpose of Cooling | Operational Impact |

|---|---|---|

| Thermal Control | Keeps fuel near 373 K | Prevents premature devolatilization and coking |

| Nozzle Integrity | Stops carbon deposit build-up | Eliminates blockages and reduces maintenance |

| Reaction Precision | Delays ignition until ejection | Ensures combustion occurs at the intended location |

| System Stability | Provides stable boundary conditions | Protects furnace shells and improves thermal control |

Maximize Your Furnace Performance with KINTEK

Don’t let injector failure or coking disrupt your critical operations. KINTEK provides industry-leading laboratory solutions backed by expert R&D and manufacturing. Our high-temperature systems, including Muffle, Tube, Rotary, Vacuum, and CVD furnaces, are fully customizable to meet your specific thermal and cooling requirements.

Whether you need precise boundary conditions for experimental research or robust hardware longevity for production, our engineers are ready to design the perfect system for you.

Ready to upgrade your thermal processing? Contact KINTEK today for a custom solution!

Visual Guide

References

- Garikai T. Marangwanda, Daniel M. Madyira. Evaluating Combustion Ignition, Burnout, Stability, and Intensity of Coal–Biomass Blends Within a Drop Tube Furnace Through Modelling. DOI: 10.3390/en18061322

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the technical advantages of using ceramic crucibles for moxa floss pyrolysis? Ensure Precise Thermal Analysis

- What is the importance of a water-cooled injector in DTF experiments? Ensure Precise Ignition Delay Measurement

- Why are a press and pelletizing molds necessary when preparing pellets for magnesium smelting? Ensure Smelting Efficiency and Control

- How do alumina ceramic furnace tubes compare to other materials like quartz or silicon carbide? Choose the Best for Your High-Temp Needs

- What is the function of an alumina boat during high-temperature activation of porous carbon? Durable Lab Solutions

- What is the technical significance of using a quartz boat in 2D superlattice preparation? Enhancing CVD Precision

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What is the function of high-purity graphite crucibles in Al-Cu-Mn master alloy prep? Ensure Chemical Purity