At its core, a circulating water vacuum pump consists of a pump body with an impeller, a water tank, a safety check valve, and a vacuum gauge. The impeller moves water to create negative pressure, the tank holds the water, the check valve prevents water from flowing backward into your system, and the gauge measures the resulting vacuum level.

The circulating water vacuum pump is more than just a mechanical device; it is a system that masterfully uses the physical properties of water to create a vacuum. It leverages a rotating ring of water as a "liquid piston" to trap and expel gas molecules, offering an oil-free and low-contamination solution for laboratory and industrial applications.

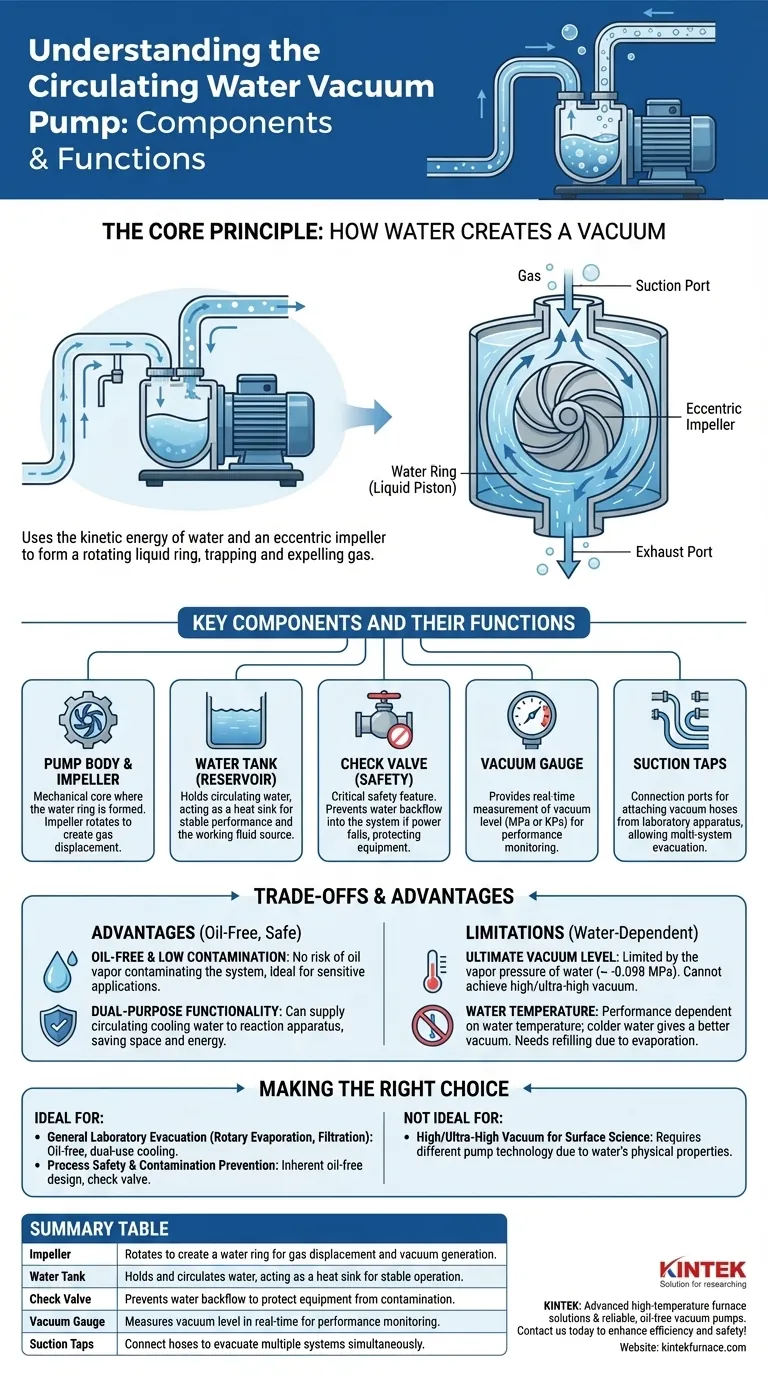

The Core Principle: How Water Creates a Vacuum

A circulating water vacuum pump, also known as a water ring pump, does not "suck" air in the traditional sense. Instead, it uses the kinetic energy of water to displace gas from a sealed container.

The Working Fluid: The Role of Water

Water is the essential working medium for this type of pump. It serves two primary functions: creating the seal for the vacuum and carrying away the heat generated during gas compression.

The Pumping Mechanism: The Eccentric Impeller

The heart of the pump is an impeller with multiple blades that is mounted eccentrically (off-center) inside a cylindrical pump casing.

As the impeller spins, centrifugal force throws the water outwards, forming a concentric liquid ring that clings to the inner wall of the casing.

Because the impeller is off-center, the space between the impeller blades and the water ring continuously changes. This cyclical change in volume is what drives the pumping action.

The "Liquid Piston" in Action

As the blades rotate toward their point of maximum distance from the casing, the volume of the space between them and the water ring increases. This expansion draws gas in from the suction port.

As the blades continue to rotate toward their closest point to the casing, the volume decreases. This action compresses the trapped gas and expels it through the exhaust port. This repeating cycle of expansion and compression effectively removes gas from the system.

A Breakdown of Key Components and Their Functions

Each component plays a critical and distinct role in the pump's operation and safety.

The Pump Body and Impeller

This is the mechanical core where the water ring is formed and the "liquid piston" action takes place. The precise engineering of the impeller and casing determines the pump's efficiency and ultimate vacuum level.

The Water Tank (Reservoir)

The integrated tank holds the circulating water. It acts as both the source for the working fluid and a heat sink, absorbing the heat of compression to maintain stable performance.

The Check Valve or Safety Bottle

This is a critical safety feature. Its sole purpose is to prevent water from being sucked back into the vacuum system or experiment if the pump is shut off or power fails. This protects sensitive equipment and chemical reactions from contamination.

The Vacuum Gauge

This component provides a real-time measurement of the vacuum level, typically in Megapascals (MPa) or Kilopascals (KPa). It allows you to monitor the pump's performance and know when your desired vacuum has been reached.

The Suction Taps

These are the connection ports where you attach the vacuum hoses from your apparatus (e.g., a rotary evaporator or filtration flask). Many models have multiple taps to evacuate more than one system simultaneously.

Understanding the Trade-offs and Advantages

No single tool is perfect for every job. Understanding the unique characteristics of a water pump is key to using it effectively.

Key Advantage: Oil-Free and Low Contamination

Because the pump uses only water as its working fluid, there is no risk of oil vapor contaminating your vacuum system or samples. This is a massive advantage in chemical, pharmaceutical, and food processing applications.

Key Advantage: Dual-Purpose Functionality

Beyond creating a vacuum, the pump can simultaneously supply circulating cooling water to your reaction apparatus. This dual functionality saves space, energy, and the cost of a separate chiller.

Limitation: Ultimate Vacuum Level

The deepest vacuum a water pump can achieve is physically limited by the vapor pressure of the water itself. This means it cannot reach the high or ultra-high vacuum levels possible with oil-sealed or dry scroll pumps. A typical ultimate vacuum is around -0.098 MPa.

Limitation: Water Temperature and Consumption

The pump's performance is dependent on the water temperature; colder water results in a better vacuum. Additionally, some water will be lost to evaporation over time and may need to be refilled for long-running operations.

Making the Right Choice for Your Application

Use these guidelines to determine if this pump fits your specific needs.

- If your primary focus is general laboratory evacuation (e.g., rotary evaporation, filtration): This pump is an ideal, low-maintenance choice due to its oil-free operation and dual-use cooling capability.

- If your primary focus is achieving high or ultra-high vacuum for sensitive surface science: You will need a different pump technology, as a water pump's vacuum is limited by water's physical properties.

- If your primary focus is process safety and preventing sample contamination: The inherent oil-free design and integrated check valve make this a highly reliable and safe option for most chemical processes.

Understanding these components and their interplay empowers you to leverage this robust tool safely and effectively in your work.

Summary Table:

| Component | Function |

|---|---|

| Impeller | Rotates to create a water ring for gas displacement and vacuum generation |

| Water Tank | Holds and circulates water, acting as a heat sink for stable operation |

| Check Valve | Prevents water backflow to protect equipment from contamination |

| Vacuum Gauge | Measures vacuum level in real-time for performance monitoring |

| Suction Taps | Connect hoses to evacuate multiple systems simultaneously |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable, oil-free vacuum pumps and custom systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance efficiency and safety in your applications!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What function do high-strength graphite molds serve? Essential Roles in Ti-6Al-4V Vacuum Hot Pressing

- What is the core function of a high-purity quartz crucible? Ensuring Success in Czochralski Silicon Growth

- Why is a high-purity quartz glass stirring rod used for phosphor dispersion? Key Benefits for Optical Glass Purity

- What are the common uses for Alumina ceramic tubes? Ideal for High-Temp, Insulation, and Corrosion Resistance

- Why is a high-purity alumina crucible used for cored wire experiments? Ensure Zero-Contamination Heat Transfer

- How does the SOM method enhance titanium alloy purity? The Power of Solid Electrolyte Tubes

- Why is a corundum crucible required for the sintering of manganese ore at 1200 °C? Ensure High-Purity Results

- Why is an alumina crucible necessary for g-C3N4 synthesis? Ensure High Purity & Stability in Polycondensation