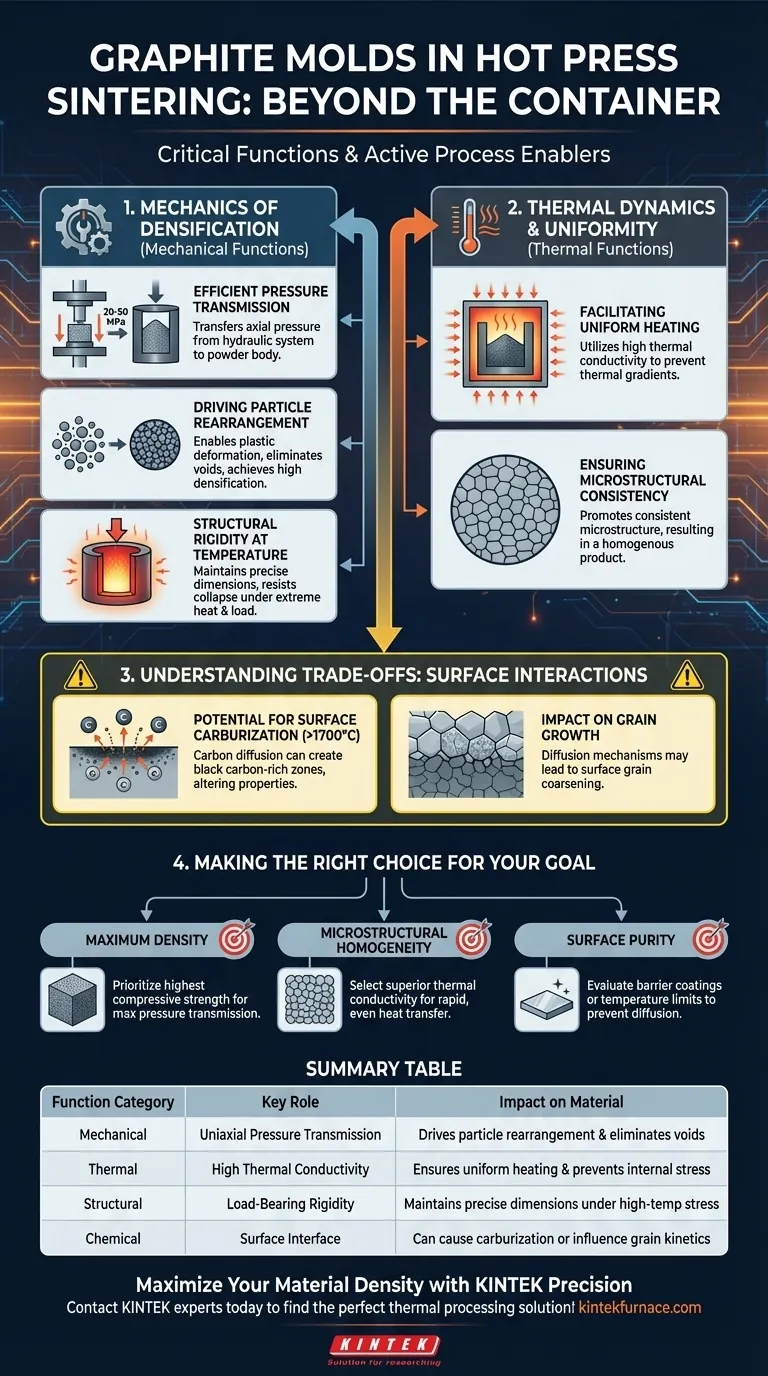

Beyond acting as a simple vessel for shaping powder, graphite molds serve as the primary mechanical and thermal interface in the hot press sintering process. They function as a critical transmission medium, bridging the gap between external hydraulic forces and the internal microstructure of the material while withstanding extreme environments.

Core Takeaway Graphite molds are active process enablers that drive densification by transmitting significant uniaxial pressure and ensuring thermal uniformity. Their high-temperature strength allows them to convert hydraulic force into particle rearrangement, while their chemical stability generally prevents erosion during the sintering cycle.

The Mechanics of Densification

Efficient Pressure Transmission

The primary active function of the graphite mold is to act as a load-bearing medium. It directly transfers the axial pressure (typically ranging from 20 MPa to 50 MPa) from the hydraulic system to the powder body within.

Driving Particle Rearrangement

By effectively transmitting this mechanical force, the mold enables the plastic deformation and rearrangement of powder particles. This mechanical action is essential for eliminating voids and achieving the high densification required for high-performance bulk materials.

Structural Rigidity at Temperature

To function correctly, the mold must possess exceptional high-temperature strength. It acts as a rigid constraint that will not deform or collapse under heavy loads, ensuring the final product maintains precise dimensions despite the extreme heat and pressure.

Thermal Dynamics and Uniformity

Facilitating Uniform Heating

Graphite’s excellent thermal conductivity is utilized to transfer heat evenly from the furnace elements to the internal powder sample. This function is vital for preventing thermal gradients that could lead to warping or internal stresses.

Ensuring Microstructural Consistency

By ensuring the sample is heated uniformly, the mold promotes a consistent microstructure throughout the material. This prevents localized disparities in grain growth or density, resulting in a homogenous final product.

Understanding the Trade-offs: Surface Interactions

While the primary reference highlights the chemical stability of graphite, it is critical to recognize specific limitations at the extremes of the process.

Potential for Surface Carburization

At extremely high temperatures (e.g., above 1700°C), the chemical inertness of the mold can degrade. Carbon from the mold may diffuse into the sample surface, creating black carbon-rich zones that can alter thermal and mechanical properties.

Impact on Grain Growth

Direct contact between the graphite and the sample can occasionally influence surface grain kinetics. Diffusion mechanisms at the interface may lead to surface grain coarsening, which requires careful consideration during process design.

Making the Right Choice for Your Goal

To optimize your sintering process, align your mold strategy with your specific material requirements:

- If your primary focus is Maximum Density: Prioritize mold designs and graphite grades with the highest compressive strength to maximize the transmission of uniaxial pressure (up to 50 MPa) without deformation.

- If your primary focus is Microstructural Homogeneity: Select graphite grades with superior thermal conductivity to ensure rapid and even heat transfer to the powder core.

- If your primary focus is Surface Purity at Extreme Temperatures: Evaluate the need for barrier coatings or temperature limits to prevent carbon diffusion and surface carburization.

The graphite mold is not merely a container; it is a sophisticated tool that dictates the mechanical and thermal success of the sintering cycle.

Summary Table:

| Function Category | Key Role of Graphite Mold | Impact on Material |

|---|---|---|

| Mechanical | Uniaxial Pressure Transmission | Drives particle rearrangement and eliminates voids |

| Thermal | High Thermal Conductivity | Ensures uniform heating and prevents internal stress |

| Structural | Load-Bearing Rigidity | Maintains precise dimensions under high-temp stress |

| Chemical | Surface Interface | Can cause carburization or influence grain kinetics |

Maximize Your Material Density with KINTEK Precision

Don't let subpar tooling compromise your research. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside high-performance lab furnaces customizable for your unique sintering needs. Whether you are aiming for maximum density or microstructural homogeneity, our equipment provides the stability and control you require.

Contact KINTEK experts today to find the perfect thermal processing solution for your laboratory!

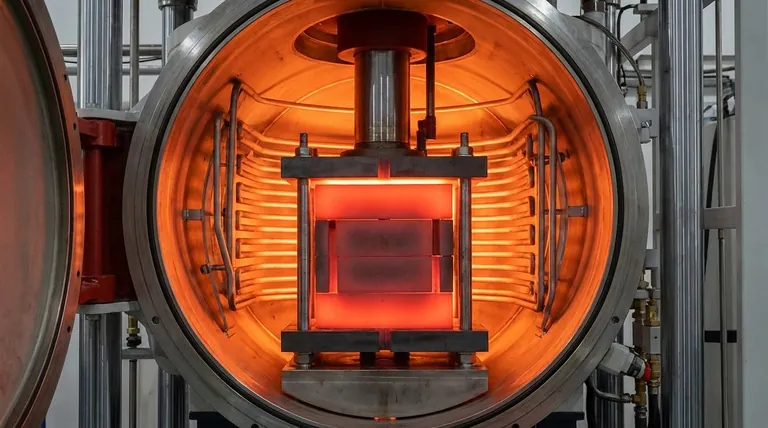

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why are alumina crucibles used for titanium alkoxide nitridation? Ensure High-Purity Synthesis Results

- What is the function of high-vacuum quartz sealing tubes in TiCo1-xCrxSb heat treatment? Ensure Alloy Purity

- Why is a laboratory-grade high-pressure reactor essential for TiO2 nanoparticles? Optimize Purity and Efficiency

- How does a vacuum sealing device protect the experimental environment? Ensure Purity in High-Temp Compression Tests

- What is the function of the substrate heating system for WS2 thin films? Optimize Crystallinity and Adhesion

- Why is precise temperature sensor placement critical in high-temp viscometers? Expert Insights for Accurate Melt Data

- Why is a laboratory drying oven or heating plate necessary for Ba7Nb4MoO20? Optimize Slurry Synthesis Results

- How do carbon composite conveyor belts affect brazing filler metal spreading? Achieve Precision Joint Stability