The integrity of viscosity data relies on thermal precision. In high-temperature oscillating cup viscometers, sensors typically cannot directly contact the fluid. Consequently, the sensor must be placed in a metal thermowell immediately adjacent to the cup bottom to ensure the recorded temperature matches the actual melt temperature as closely as possible.

Because direct immersion is rarely feasible, temperature sensors must be housed in a metal finger positioned against the cup's base. This precise proximity minimizes systemic deviation, allowing for accurate thermodynamic data when paired with proper calibration.

The Physical Constraints of the System

The Limitation of Direct Contact

In many high-temperature viscosity experiments, you cannot simply dip a thermometer into the sample. The measurement cup is often enclosed, and the harsh environment may damage sensitive instruments like platinum resistance thermometers or thermocouples.

The Necessity of Indirect Measurement

Because of these physical barriers, temperature measurement in these systems is inherently indirect. You are measuring the environment surrounding the sample, rather than the sample itself. This introduces a risk of thermal discrepancy.

Optimizing Sensor Placement

The Role of the Thermowell

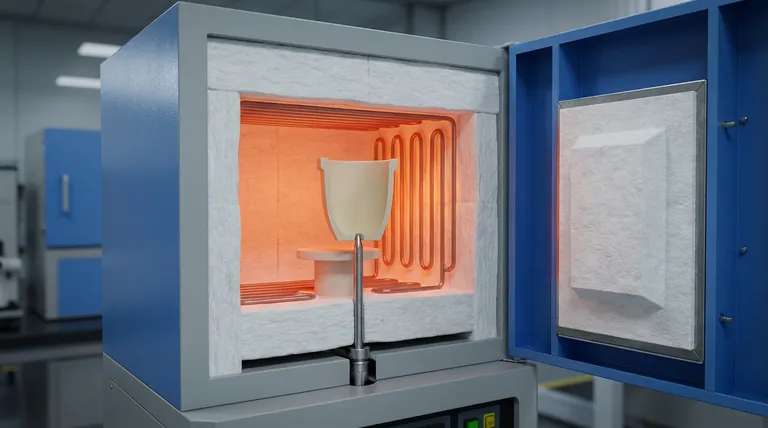

To facilitate accurate readings without direct contact, sensors are positioned within a dedicated metal thermowell or "metal finger." This metal housing protects the sensor while serving as a thermal conductor between the heat source, the cup, and the sensor.

Critical Positioning at the Cup Bottom

The tip of this metal finger must be located immediately adjacent to the bottom of the cup. This is the critical design feature. Placing the sensor anywhere else introduces significant thermal lag and inaccurate gradients.

Minimizing Systemic Deviation

The goal of this specific physical positioning is to minimize systemic deviation. This is the error gap between what the sensor reads and the true temperature of the melt inside the cup. The closer the physical coupling, the smaller this gap becomes.

Understanding the Trade-offs

The Inevitability of Error

Even with perfect mechanical alignment, indirect measurement is never 100% accurate on its own. There will always be a slight thermal resistance between the cup wall and the sensor.

Reliance on Calibration

You cannot rely solely on the hardware placement. The physical setup reduces the error, but it does not eliminate it entirely. If you neglect the software side of the equation—specifically calibration—your data will remain skewed.

The Role of Blank Experiments

To account for the remaining deviation, you must perform system calibration via blank experiments. These experiments quantify the specific offset of your machine, allowing you to mathematically correct the data to achieve true thermodynamic accuracy.

Ensuring Accuracy in Your Experiments

To ensure your viscosity measurements are valid, you must address both the physical setup and the experimental procedure.

- If your primary focus is Equipment Setup: Ensure the metal thermowell is installed so it sits flush against or immediately adjacent to the measurement cup bottom.

- If your primary focus is Data Analysis: Always correct your raw temperature readings using data derived from blank calibration experiments to account for systemic deviation.

Physical proximity minimizes the error, but only rigorous calibration eliminates it.

Summary Table:

| Feature | Importance in Viscometry | Key Benefit |

|---|---|---|

| Thermowell Finger | Protects sensor from harsh environments | Ensures sensor longevity |

| Bottom Placement | Minimizes thermal lag and gradients | Closer match to actual melt temp |

| Indirect Sensing | Avoids sample contamination/interference | Maintains sample integrity |

| Blank Calibration | Corrects inherent systemic deviations | Achieves true thermodynamic data |

Maximize Your Research Precision with KINTEK

Precise thermal control is the backbone of reliable high-temperature material science. KINTEK empowers your laboratory with cutting-edge high-temp solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are measuring viscosity or conducting complex thermal analysis, our customizable systems are backed by expert R&D and manufacturing to meet your most demanding specifications.

Ready to eliminate systemic deviation in your lab?

Contact KINTEK Today to discuss your unique needs with our technical specialists.

References

- V. M. B. Nunes, C. A. Nieto de Castro. Correct Use of Oscillating-Cup Viscometers for High-Temperature Absolute Measurements of Newtonian Melts. DOI: 10.1007/s10765-024-03355-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a MgO crucible preferred for VCD? Achieve 3ppm Purity in High-Temperature Metallurgy

- Which industries can benefit from using the circulating water multifunctional vacuum pump? Discover Clean, Efficient Vacuum Solutions

- What is the primary function of a drying oven during LLZTO preparation? Ensure Pure Phase Solid Electrolytes

- How does a laboratory drying oven function in catalyst synthesis? Secure Precision Metal Precursor Stabilization

- What are the advantages of using graphite for Sb2S3 sulfurization? Enhancing Thermal Precision and Safety

- What is the function of molybdenum fixtures in high-temperature heat treatment? Ensure Perfect Diffusion Integrity

- What are the advantages of using high-purity quartz boats? Ensure Purity in Carbon Nanotube Synthesis

- Why is a high-pressure MFC necessary for CHP systems? Achieve Precision in Catalytic Hydropyrolysis Data