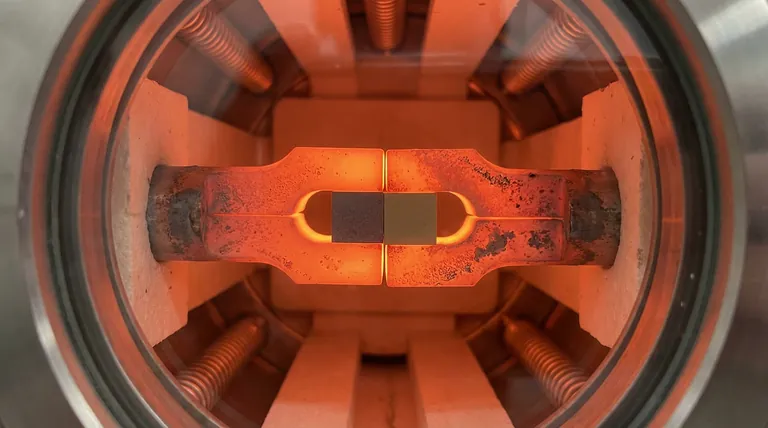

The primary function of molybdenum fixtures is to act as a stable, high-strength containment mechanism during extreme thermal processing. specifically during heat treatment at temperatures around 1150 °C, these fixtures apply continuous mechanical pressure to diffusion couples. This pressure ensures the interfaces of the two specimens remain in tight contact, preventing the separation that typically results from differences in thermal expansion.

Molybdenum fixtures utilize their high melting point to maintain structural rigidity at 1150 °C, ensuring stable pressure that counteracts thermal expansion forces and preserves the critical interface contact required for diffusion.

The Physical Necessity of Molybdenum

To understand why molybdenum is chosen over standard tooling materials, one must look at the thermal environment of the process.

Extreme Thermal Stability

Molybdenum possesses an exceptionally high melting point. This property is fundamental for any fixture subjected to temperatures exceeding 1000 °C.

Retaining Strength at 1150 °C

At the specific processing temperature of 1150 °C, most standard alloys would soften or melt. Molybdenum retains excellent mechanical strength, allowing it to function as a rigid clamp rather than deforming under the heat.

The Role of Mechanical Pressure

The fixture is not merely a holder; it is an active mechanical component in the diffusion process.

Ensuring Interface Integrity

For diffusion couples to interact effectively, the materials must share a seamless boundary. The molybdenum fixture applies stable mechanical pressure to force the two specimens together.

Counteracting Thermal Expansion

As materials heat up, they expand at different rates. Without external constraint, this differential expansion would cause the specimens to pull apart at the interface.

Preventing Separation

The fixture creates a mechanical barrier against this expansion. By maintaining tight contact throughout the entire diffusion cycle, it prevents physical separation gaps from forming between the specimens.

Understanding the Constraints

While molybdenum fixtures are highly effective, it is important to understand the operational principles that dictate their success.

The Requirement for Rigidity

The entire process relies on the fixture being stronger than the thermal expansion forces of the samples. If the fixture material were to yield even slightly at 1150 °C, the pressure would drop, and the interface would likely delaminate.

Temperature Specificity

The effectiveness of this setup is highlighted at 1150 °C. Using fixtures with lower melting points or lower high-temperature strength would result in immediate mechanical failure of the assembly.

Making the Right Choice for Your Goal

When designing experiments involving diffusion couples, the choice of fixture material is as critical as the specimens themselves.

- If your primary focus is High-Temperature Integrity: Select molybdenum to ensure the fixture retains its shape and strength at temperatures as high as 1150 °C.

- If your primary focus is Interface Quality: Rely on the stable mechanical pressure of molybdenum fixtures to neutralize thermal expansion and prevent gaps between specimens.

Success in high-temperature diffusion relies on maintaining unwavering contact pressure when thermal forces try to break it.

Summary Table:

| Feature | Function in Diffusion Couples |

|---|---|

| High Melting Point | Maintains structural integrity at extreme temperatures (>1000°C) |

| Mechanical Strength | Prevents fixture deformation or softening at 1150°C |

| Constant Pressure | Forces specimens together to ensure a seamless boundary |

| Expansion Control | Counteracts differential thermal expansion to prevent interface separation |

Optimize Your High-Temperature Diffusion Processes

Don't let thermal expansion compromise your research results. KINTEK provides the high-performance thermal solutions you need to maintain precision under pressure. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temperature furnaces designed for your unique material science requirements.

Ready to elevate your lab's capabilities? Contact us today to discuss how our customizable high-temperature systems can support your next breakthrough.

References

- Lukas Haußmann, Mathias Göken. Interdiffusion Coefficients and Strengthening Effects of Nb, Ta, and Zr in the α2-Ti3Al Phase. DOI: 10.1007/s11669-024-01105-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How is an industrial electric heating drying oven utilized in the pretreatment of copper-graphite composite materials?

- What is the function of graphite molds in the Spark Plasma Sintering (SPS) of high-entropy alloys?

- What are the technical considerations for selecting a graphite crucible? Expert Insights for Molten Salt Electrolysis

- Why are high-purity alumina crucibles used for LLZO sintering? Master Lithium Volatility Control

- Why Use Vacuum-Sealed Quartz Tubes for CVT CIPS Synthesis? Ensuring Purity and Precision

- What functions does the hot pressing mold perform? Key Roles in Al3Ti/Al Composite Powder Metallurgy

- How does the optical clarity of quartz tubes benefit laboratory processes? Enhance Control and Accuracy in High-Temp Experiments

- What is the role of mass flow controllers (MFC) in 2DP-F film preparation? Achieve High-Precision Synthesis Control