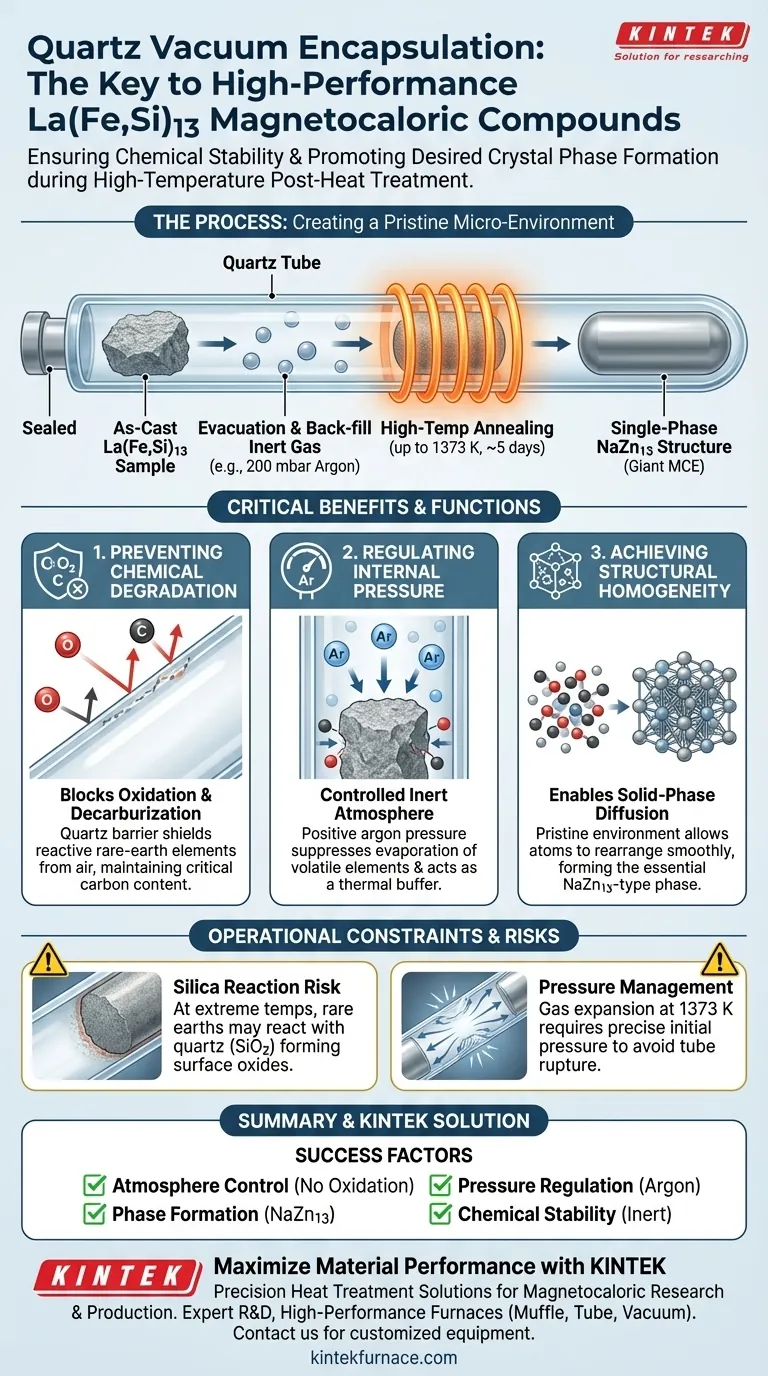

Quartz vacuum encapsulation is the primary method for isolating La(Fe,Si)13-based alloys to ensure chemical stability during high-temperature synthesis. Specifically, sealing as-cast samples under a controlled atmosphere—typically 200 mbar of Argon—shields the material from oxidation and decarburization while it undergoes the extensive annealing required to form the correct crystal phase.

The core function of this technique is to create a pristine, inert environment that facilitates smooth solid-phase diffusion. Without this isolation, the reactive rare-earth elements would degrade before the material could achieve the critical single-phase NaZn13-type structure.

The Critical Role of Environmental Isolation

Preventing Chemical Degradation

La(Fe,Si)13 compounds require aggressive heat treatment, often reaching 1373 K for durations as long as five days.

Exposing rare-earth alloys to open air at these temperatures guarantees rapid oxidation.

Quartz encapsulation prevents this by creating a physical barrier. It also specifically prevents decarburization, ensuring that the carbon content—often critical for tuning magnetic properties—remains stable throughout the process.

Regulating Internal Pressure

The encapsulation is not just a vacuum; it is often back-filled with a specific pressure of inert gas, such as 200 mbar of Argon.

This positive pressure serves a dual purpose: it suppresses the evaporation of volatile elements and provides a thermal buffer.

maintaining a consistent protective pressure is vital for the stability of the sample surface during long-duration heating.

Achieving Structural Homogeneity

Enabling Solid-Phase Diffusion

As-cast alloys are rarely usable in their raw state due to compositional segregation.

To correct this, atoms must physically rearrange themselves within the solid material.

Encapsulation allows this solid-phase diffusion reaction to proceed smoothly over several days without the interference of surface contaminants that could inhibit atomic movement.

Forming the NaZn13-Type Phase

The ultimate goal of this post-heat treatment is to obtain a single-phase NaZn13-type crystal structure.

This specific cubic structure is responsible for the giant magnetocaloric effect (MCE) in these compounds.

If the atmosphere is not strictly controlled via encapsulation, impurity phases form, preventing the stabilization of the NaZn13 structure and severely degrading magnetic performance.

Operational Constraints and Trade-offs

The Risk of Silica Reaction

While quartz is thermally stable, it is not perfectly inert in all conditions.

At extremely high temperatures, there is a risk of the rare-earth elements reacting with the silica ($SiO_2$) in the tube, potentially creating a surface oxide layer.

Pressure Management

Sealing samples under partial argon pressure requires careful calculation.

As the tube heats to 1373 K, the gas expands significantly. If the initial pressure is too high, or the tube volume is too small, the capsule may rupture during the annealing process.

Making the Right Choice for Your Synthesis

To maximize the performance of your magnetocaloric materials, consider your specific processing goals:

- If your primary focus is Phase Purity: Ensure your encapsulation includes a partial pressure of Argon (around 200 mbar) rather than a hard vacuum to suppress volatility while preventing oxidation.

- If your primary focus is Structural Integrity: Carefully clean the as-cast samples before encapsulation to ensure no surface contaminants interfere with the solid-state diffusion required for the NaZn13 phase.

Success in synthesizing La(Fe,Si)13 compounds relies not just on the temperature of the furnace, but on the integrity of the micro-environment created inside the quartz tube.

Summary Table:

| Feature | Quartz Vacuum Encapsulation Benefit |

|---|---|

| Atmosphere Control | Prevents oxidation and decarburization of rare-earth elements. |

| Phase Formation | Facilitates solid-phase diffusion to achieve NaZn13-type structure. |

| Pressure Regulation | Argon back-filling (e.g., 200 mbar) suppresses volatile element evaporation. |

| Chemical Stability | Creates an inert environment for high-temperature annealing (up to 1373 K). |

| Performance Impact | Ensures maximum giant magnetocaloric effect (MCE) by eliminating impurities. |

Maximize Your Material Performance with KINTEK

Precision heat treatment is the cornerstone of advanced material synthesis. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of magnetocaloric research and industrial production.

Whether you require precise atmosphere control for quartz encapsulation or customizable high-temperature furnaces for solid-phase diffusion, our solutions are tailored to your unique needs.

Ready to elevate your lab's efficiency and achieve superior phase purity?

Contact KINTEK today for expert guidance and customized equipment solutions.

Visual Guide

References

- Fengqi Zhang, Yang Ren. Engineering Light‐Element Modified LaFe <sub>11.6</sub> Si <sub>1.4</sub> Compounds Enables Tunable Giant Magnetocaloric Effect. DOI: 10.1002/advs.202416288

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the purpose of using integrated temperature controllers for CuInP2S6? Master CIPS Electrical Characterization

- What mechanical properties should be evaluated for alumina ceramic furnace tubes? Ensure Durability and Performance

- What are the main reasons for the alumina furnace tube being prone to breaking? Prevent Costly Failures with Expert Tips

- What is the primary function of the transparent quartz tube in the Floating-Zone technique? Optical & Atmospheric Control

- What are the advantages of water circulating vacuum pumps? Discover Oil-Free, Reliable Solutions for Clean Processes

- Why is an alumina crucible necessary when synthesizing U0.92Mn3Si2C inside a quartz tube? Ensure Vessel Integrity

- What is the function of a precision oven in drying resin-impregnated wood? Optimize Your Bonding & Structural Integrity

- Why is a high-precision Mass Flow Controller necessary for E-Ni/m-MgAlOx catalysts? Ensure Precise Gas Dynamics