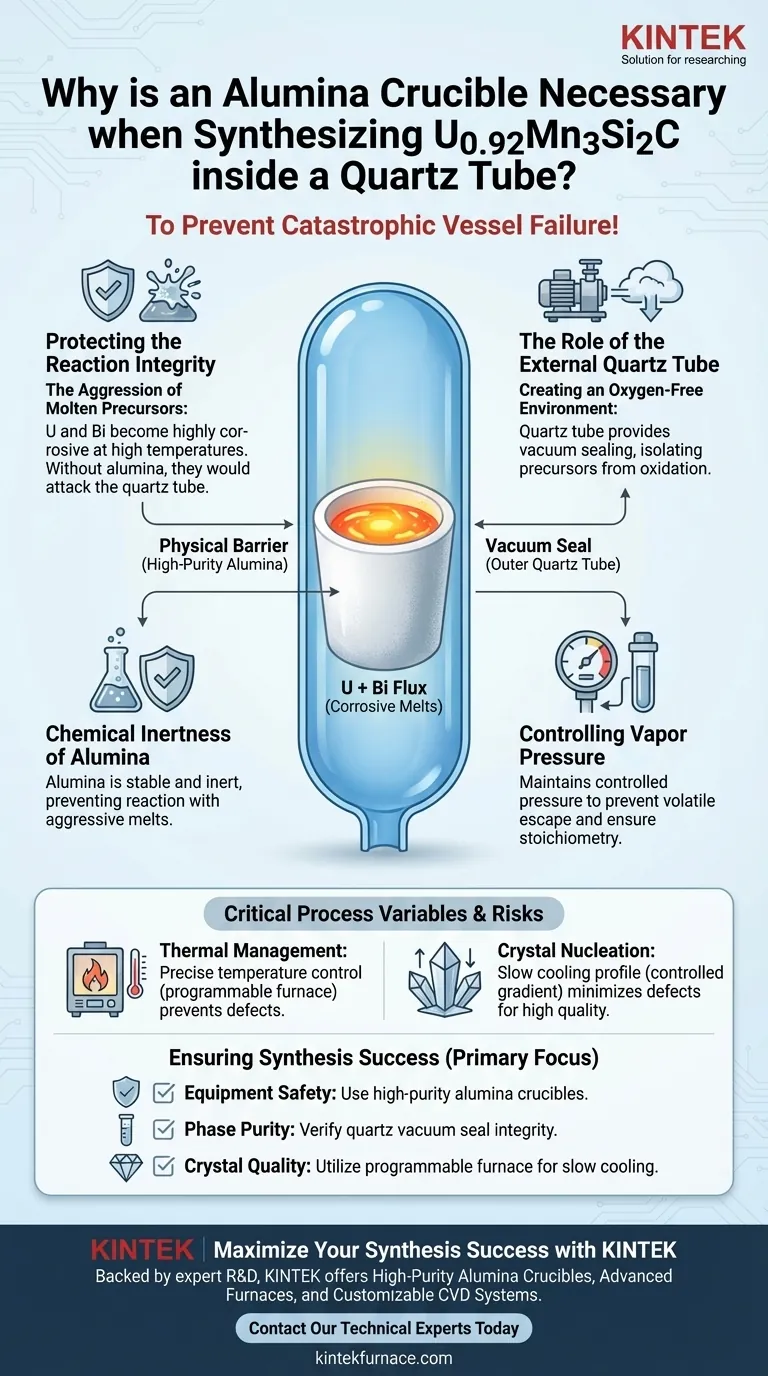

An alumina crucible is mandatory to prevent catastrophic vessel failure. The synthesis process utilizes metallic uranium and bismuth flux, both of which are chemically aggressive at high temperatures. An alumina crucible acts as a physical barrier, preventing these molten precursors from coming into direct contact with the quartz tube, which would otherwise suffer severe corrosion or breach under reaction conditions.

The synthesis of U0.92Mn3Si2C requires a dual-layer containment strategy: the alumina crucible provides chemical inertness against molten metals, while the outer quartz tube maintains the necessary vacuum environment.

Protecting the Reaction Integrity

The primary challenge in this synthesis is managing the extreme reactivity of the precursor materials. The following sections detail why the alumina crucible is the specific solution to this problem.

The Aggression of Molten Precursors

The synthesis of U0.92Mn3Si2C involves metallic uranium and bismuth flux.

At the elevated temperatures required for this reaction, these elements become highly corrosive. If allowed to touch the silicate structure of a standard quartz tube, the molten mixture would attack the walls, leading to etching, cracking, or a complete breach of the vessel.

Chemical Inertness of Alumina

High-purity alumina is chosen specifically for its resistance to this type of chemical attack.

It remains stable and inert even when in prolonged contact with aggressive melts like uranium and bismuth. By placing the reactants inside the alumina crucible, you ensure that the containment vessel does not become a participant in the chemical reaction.

The Role of the External Quartz Tube

While the alumina crucible handles the "heavy lifting" regarding chemical corrosion, the quartz tube serves a different, equally critical function related to the atmosphere of the reaction.

Creating an Oxygen-Free Environment

The quartz tube is essential for vacuum sealing.

Uranium precursors are highly susceptible to oxidation. The quartz tube isolates the alumina crucible and its contents from the outside atmosphere, ensuring a strictly closed, oxygen-free environment.

Controlling Vapor Pressure

The sealed quartz tube maintains controlled vapor pressure during heating.

This closed system is a prerequisite for maintaining the desired stoichiometry. Without this sealed environment, volatile components might escape, altering the chemical balance and preventing the formation of phase-pure U0.92Mn3Si2C.

Critical Process Variables and Risks

Understanding the interplay between your materials and your equipment is vital for avoiding defects.

Thermal Management

Precise temperature control is just as important as material selection.

Using a programmable box furnace allows you to manage heating rates and dwell times. This control prevents temperature fluctuations that could lead to crystal defects or the formation of secondary phases.

Crystal Nucleation

The cooling profile dictates the quality of your single crystals.

Accurate temperature gradient control ensures that crystal nuclei precipitate slowly under appropriate supersaturation levels. This slow growth is necessary to minimize defects and achieve the structural integrity required for the final product.

Ensuring Synthesis Success

The choice of materials in this synthesis is not arbitrary; it is a calculated decision to balance chemical aggression with atmospheric control.

- If your primary focus is Equipment Safety: Ensure you are using high-purity alumina crucibles to prevent molten flux from corroding through the containment and damaging your furnace.

- If your primary focus is Phase Purity: Verify the integrity of the quartz vacuum seal to prevent oxidation and maintain strict stoichiometry during the reaction.

- If your primary focus is Crystal Quality: Utilize a programmable furnace to enforce slow cooling profiles, ensuring nuclei precipitate without defects.

By isolating the corrosive melt in alumina while maintaining a vacuum in quartz, you create the only environment in which U0.92Mn3Si2C can successfully form.

Summary Table:

| Component | Role in Synthesis | Key Benefit |

|---|---|---|

| Alumina Crucible | Inner reaction vessel | Chemical inertness against corrosive molten metals/flux |

| Quartz Tube | Outer containment | Provides vacuum seal and prevents oxidation |

| Metallic Uranium | Active reactant | Highly reactive; requires alumina protection |

| Bismuth Flux | Solvent medium | Aggressive at high temps; safely contained by alumina |

| Vacuum Seal | Atmospheric control | Maintains stoichiometry and prevents contamination |

Maximize Your Synthesis Success with KINTEK

Precision material synthesis like U0.92Mn3Si2C demands equipment that can withstand extreme chemical environments and maintain rigorous atmospheric control. KINTEK provides the high-performance tools you need to prevent vessel failure and ensure phase purity.

Backed by expert R&D and manufacturing, we offer a comprehensive range of lab solutions including:

- High-Purity Alumina & Ceramic Crucibles for corrosive melt containment.

- Advanced Muffle, Tube, and Vacuum Furnaces for precise thermal management.

- Customizable CVD and High-Temp Systems tailored to your unique research needs.

Don't risk your experimental integrity—trust the lab specialists at KINTEK to provide the durability and precision your research deserves.

Contact Our Technical Experts Today

Visual Guide

References

- Hope A. Long, Vladislav V. Klepov. Synthesis of U<sub>0.92</sub>Mn<sub>3</sub>Si<sub>2</sub>C Using Organic Carbon Source. DOI: 10.1002/zaac.202500047

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What advantages do boron nitride (BN) crucibles offer for molten FUNaK salt? Ensure Purity & High-Temp Stability

- What is the importance of the constant temperature environment provided by a heating stage? Expert Lab Solutions

- What role does a high-density MgO crucible play in slag reduction experiments? Ensure Pure Results at 1600°C

- What is the purpose of waveguide-to-coax adapters? Key Roles in High-Temperature Measurement Chains

- What is the purpose of using a high-purity ceramic crucible with a sealed lid during the thermal treatment of biochar?

- How does an in-situ reaction chamber in HTXRD facilitate BiFeO3 synthesis study? Mapping Real-Time Phase Evolution

- What are the requirements for sealed quartz tubes for CVT? Ensure High Purity & Integrity for NiI2 and MnPS3 Growth

- What considerations lead to the selection of a corundum crucible for CVD sulfurization? Ensure Peak Sample Purity