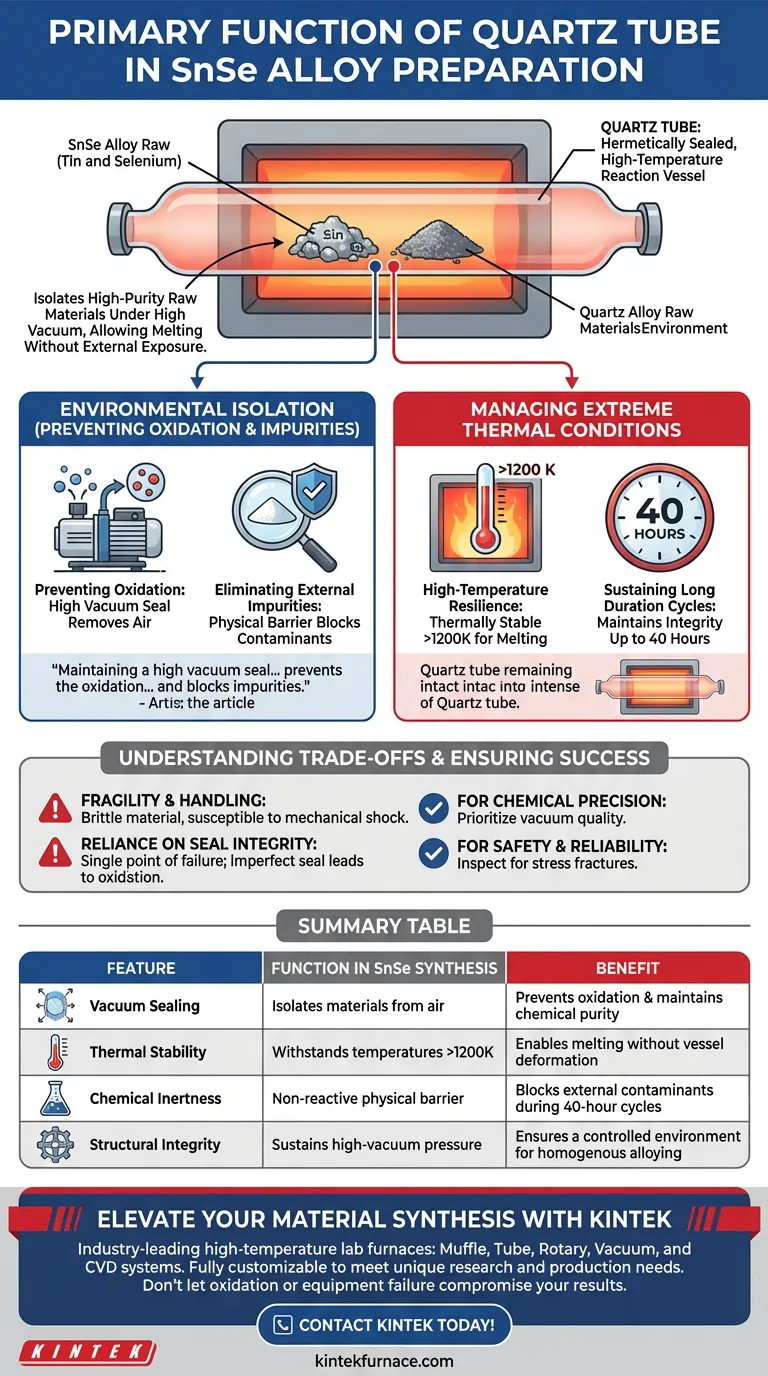

The primary function of a quartz tube in the preparation of Tin Selenide (SnSe) alloys is to serve as a hermetically sealed, high-temperature reaction vessel. It isolates high-purity raw materials under a high vacuum, allowing them to undergo melting without exposure to the external environment.

By maintaining a high vacuum seal, the quartz tube prevents the oxidation of active components and blocks impurities, which is essential for preserving the precise chemical composition of the alloy during extended heating cycles.

The Necessity of Environmental Isolation

In materials science, the environment in which an alloy is synthesized is just as critical as the raw materials themselves. The quartz tube addresses two fundamental challenges in SnSe preparation.

Preventing Oxidation

The active components in Tin Selenide alloys are highly reactive to oxygen, especially when heated.

The quartz tube is sealed under a high vacuum to remove air entirely. This isolation ensures that the raw materials do not oxidize, which would fundamentally alter the properties of the final material.

Eliminating External Impurities

Even microscopic contaminants can degrade the performance of a semiconductor alloy.

By encapsulating the raw materials, the tube acts as a physical barrier. It prevents the introduction of foreign particles during the handling and melting stages, ensuring the final alloy maintains high purity.

Managing Extreme Thermal Conditions

The synthesis of SnSe is a rigorous thermal process. The vessel used must possess specific physical properties to survive the procedure.

High-Temperature Resilience

The melting process requires temperatures exceeding 1200 K.

Standard glass or metal containers would likely melt, deform, or react with the alloy at these temperatures. Quartz is selected because it remains thermally stable and chemically inert under these extreme conditions.

Sustaining Long Duration Cycles

The formation of a homogenous alloy is not instantaneous.

The melting process can last up to 40 hours. The quartz tube must maintain its structural integrity and vacuum seal throughout this prolonged exposure to high heat without degrading.

Understanding the Trade-offs

While quartz tubes are the industry standard for this process, they introduce specific constraints that must be managed.

Fragility and Handling

Quartz is a brittle material. Despite its high thermal tolerance, it is susceptible to mechanical shock.

Great care must be taken during the loading and sealing phases to avoid micro-fractures, which could lead to catastrophic failure once the tube is under vacuum and heat.

Reliance on Seal Integrity

The entire process depends on the initial vacuum seal.

If the seal is imperfect, the long duration of the melt (40 hours) provides ample time for air to leak in. This would result in a wasted batch due to oxidation, highlighting the "single point of failure" nature of this containment method.

Ensuring Success in Alloy Preparation

To achieve the best results in SnSe synthesis, you must align your procedural checks with the function of the containment vessel.

- If your primary focus is chemical precision: Prioritize the quality of the vacuum prior to sealing; any residual air will react with the melt over the 40-hour cycle.

- If your primary focus is safety and reliability: Inspect the quartz tube for stress fractures or imperfections that could compromise the vessel when subjected to temperatures above 1200 K.

The quartz tube is not merely a container; it is the active guardian of chemical purity in the high-temperature synthesis of Tin Selenide.

Summary Table:

| Feature | Function in SnSe Synthesis | Benefit |

|---|---|---|

| Vacuum Sealing | Isolates materials from air | Prevents oxidation and maintains chemical purity |

| Thermal Stability | Withstands temperatures >1200K | Enables melting without vessel deformation |

| Chemical Inertness | Non-reactive physical barrier | Blocks external contaminants during 40-hour cycles |

| Structural Integrity | Sustains high-vacuum pressure | Ensures a controlled environment for homogenous alloying |

Elevate Your Material Synthesis with KINTEK

Precision in Tin Selenide preparation starts with the right thermal environment. KINTEK provides industry-leading high-temperature lab furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—specifically designed to handle the rigorous 1200K+ thermal cycles required for semiconductor alloys.

Backed by expert R&D and precision manufacturing, our equipment is fully customizable to meet your unique research and production needs. Don't let oxidation or equipment failure compromise your results.

Contact KINTEK today to discuss your custom furnace solution!

Visual Guide

References

- Nan Lin, Yuan Yu. Metavalent Bonding in Cubic SnSe Alloys Improves Thermoelectric Properties over a Broad Temperature Range. DOI: 10.1002/adfm.202315652

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of gold (Au), platinum (Pt), or platinum-iridium (Pt-Ir) foil in silicate melt experiments?

- Why is a high-purity quartz glass stirring rod used for phosphor dispersion? Key Benefits for Optical Glass Purity

- Why is a laboratory oven utilized during the pre-treatment stage of chicken bone waste pyrolysis?

- What function does a PTFE liner serve in NiWO4 synthesis? Ensure Purity & Prevent Corrosion in Hydrothermal Reactors

- What role does a high-temperature heating stage play in characterizing the thermal stability of piezoelectric ceramics?

- Why is a U-shaped quartz reactor required for H2-TPR? Ensure Precision for Cu–Ce/HZSM-5 Analysis

- How does Energy Dispersive X-ray Spectroscopy (EDX) assist in adjusting furnace parameters? Biochar Quality Control

- What is the role of a Teflon-lined autoclave in CeO2 synthesis? Achieve Pure, Monodisperse Nanomaterials