Energy Dispersive X-ray Spectroscopy (EDX) acts as the primary feedback mechanism for optimizing high-temperature furnace operations by quantifying the elemental transformation of biomass into biochar. By analyzing specific chemical shifts—most notably the ratio of carbon to oxygen—operators can determine the precise extent of carbonization. This data informs the adjustment of critical furnace variables, such as peak temperature and heating duration, to ensure the final product achieves maximum chemical stability and energy density.

EDX data bridges the gap between raw furnace settings and material quality, allowing operators to move beyond theoretical setpoints. By revealing the exact degree of deoxygenation and mineral concentration, it enables the fine-tuning of thermal profiles to produce biochar with targeted microstructural characteristics.

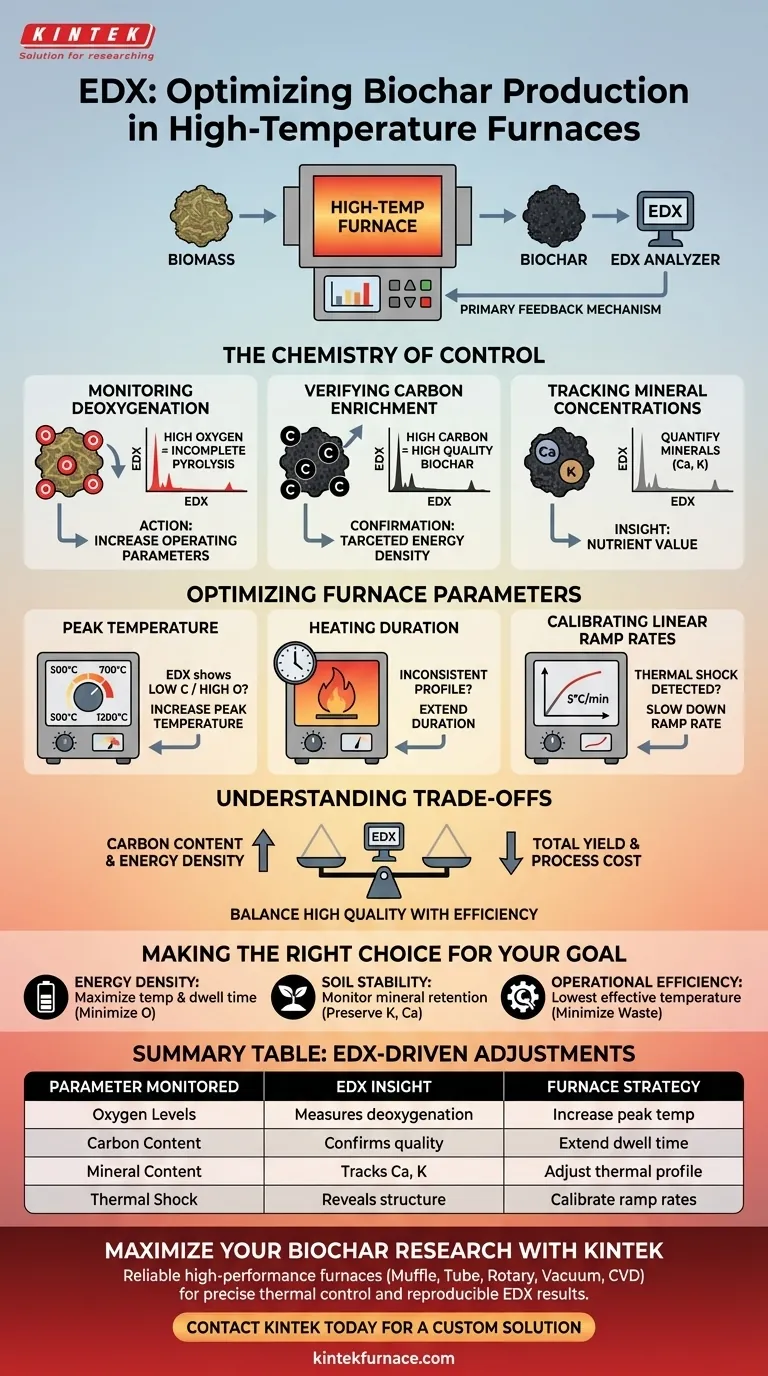

The Chemistry of Control

To understand how to adjust a furnace, you must first understand what the furnace is doing to the material. EDX provides a window into this chemical process.

Monitoring Deoxygenation

The primary goal of pyrolysis is removing oxygen to stabilize the carbon structure.

EDX measures the residual oxygen content in the sample. If EDX detects high oxygen levels, it indicates incomplete pyrolysis. This signals the operator that the current operating parameters are insufficient to drive off volatile components.

Verifying Carbon Enrichment

As oxygen leaves, the relative percentage of carbon increases. This is the defining characteristic of high-quality biochar.

EDX validates whether the material has reached the necessary carbon concentration. This confirmation is essential for applications requiring high energy density or specific adsorption capabilities.

Tracking Mineral Concentrations

EDX also quantifies inorganic elements like calcium (Ca) and potassium (K).

Because these minerals do not vaporize at standard pyrolysis temperatures, their concentration increases relative to the total mass. Monitoring these levels helps confirm that the biomass has been reduced effectively and provides insight into the biochar's potential nutrient value.

Optimizing Furnace Parameters

Once EDX provides the elemental data, it is used to adjust the specific mechanics of the high-temperature furnace.

Fine-Tuning Peak Temperature

High-precision furnaces allow for exact temperature settings, often ranging up to 1200°C.

If EDX data shows insufficient carbonization (low carbon, high oxygen), the operator must increase the peak pyrolysis temperature. Common investigation points are 500°C, 600°C, and 700°C. EDX helps identify the "sweet spot" where carbon content is maximized without unnecessary energy expenditure.

Adjusting Heating Duration

Sometimes the temperature is correct, but the material hasn't been exposed to it long enough.

If the elemental profile is inconsistent or shows only partial carbonization, the heating duration (residence time) should be extended. This allows the heat to penetrate the biomass fully, ensuring uniform deoxygenation.

Calibrating Linear Ramp Rates

Advanced furnaces control how fast the temperature rises, such as a rate of 5°C per minute.

EDX analysis of samples produced at different rates can reveal how thermal shock affects the material. If the structure is compromised, operators can use this data to slow down the ramp rate, ensuring a more gradual and stable release of volatiles.

Understanding the Trade-offs

While EDX allows for maximization of carbon content, pushing parameters to the limit involves inherent compromises.

Carbon Content vs. Yield

Increasing furnace temperature invariably drives up carbon content, which EDX will confirm as a "higher quality" reading.

However, this comes at the cost of total yield. Higher temperatures cause more mass loss. Operators must balance the high carbon readings from EDX against the reduction in the total volume of saleable product.

Energy Density vs. Process Cost

Achieving the highest carbon purity requires higher temperatures or longer dwell times.

This increases the energy consumption of the furnace. You must decide if the marginal gain in carbon content (verified by EDX) justifies the additional electricity and time required to produce it.

Making the Right Choice for Your Goal

Using EDX is not just about reading numbers; it is about aligning your furnace operations with your end goals.

- If your primary focus is Energy Density: Increase furnace temperature and dwell time until EDX confirms oxygen levels have dropped to their absolute minimum.

- If your primary focus is Soil Stability: Use EDX to monitor the retention of minerals like Potassium and Calcium, ensuring temperatures are high enough to carbonize but not so high that they alter the mineral availability.

- If your primary focus is Operational Efficiency: Use EDX to find the lowest possible temperature that still achieves your baseline carbon target, minimizing energy waste.

EDX turns the "black box" of pyrolysis into a transparent process, giving you the data needed to control quality with confidence.

Summary Table:

| Parameter Monitored | EDX Insight Provided | Furnace Adjustment Strategy |

|---|---|---|

| Oxygen Levels | Measures deoxygenation extent | Increase peak temperature if oxygen is too high |

| Carbon Content | Confirms carbonization quality | Extend dwell time to reach targeted carbon density |

| Mineral Content | Tracks Ca, K, and ash buildup | Adjust thermal profile to preserve nutrient value |

| Thermal Shock | Reveals structural integrity | Calibrate linear ramp rates (e.g., 5°C/min) |

Maximize Your Biochar Research with KINTEK

Precise biochar production requires more than just heat; it demands the reliability of KINTEK’s high-performance laboratory furnaces. Backed by expert R&D and world-class manufacturing, we provide a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific pyrolysis and carbonization requirements.

Whether you are fine-tuning carbon-to-oxygen ratios or optimizing mineral retention, our equipment delivers the thermal precision necessary for reproducible EDX results. Empower your material science with the industry leader.

Contact KINTEK Today for a Custom Solution

Visual Guide

References

- Hani Hussain Sait, Bamidele Victor Ayodele. Hybrid Analysis of Biochar Production from Pyrolysis of Agriculture Waste Using Statistical and Artificial Intelligent-Based Modeling Techniques. DOI: 10.3390/agronomy15010181

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of using a quartz boat as a catalyst carrier? Optimize Purity and Kinetics in CCVD

- Why is zirconia grinding media preferred for NN-10ST ceramic powders? Ensure Purity & Dielectric Performance

- What are the technical requirements for the Quartz Boat used as a precursor container in the CVD growth of 2D In2Se3?

- What key roles do high-purity graphite molds play in SPS? Powering High-Entropy Carbide Synthesis

- What is the function of a water quenching tank? Capturing Microstructures in Weather-Resistant Steel

- What are the advantages of using high-purity quartz tubes as reaction vessels? Unlock Active Flux Synthesis

- What are the primary functions of a self-preheating heat exchanger? Maximize Thermal Efficiency in Double-P Tubes

- Why Use Vacuum-Sealed Quartz Tubes for CVT CIPS Synthesis? Ensuring Purity and Precision